This guide is an introduction for those who want to explore the potential of ceramics as a 3D printing material. First, we'll explain the fundamentals of ceramics in the following sections, and then we'll proceed with 3D printing solutions. What Do We Mean by Ceramics? Most people would identify everyday household items as ceramics. The Best Ceramic / Pottery 3D Printers by All3DP Updated Jan 4, 2022 From bowls to pots to mugs, ceramic, clay, and pottery material is ideal for 3D printing. Take a look at the latest in ceramic 3D printers. Advertisement with personalized ads Accept and continue

3D Print Ceramics Collaboration Between Art & Tech

Most 3D printed ceramics fall into the technical category but the extrusion based printing process (discussed below) works primarily with classic ceramics. Why print with ceramic? Aesthetic Tactility Chemical resistance Biocompatible High or low thermal conductivity, depending on formulation Electrical insulator Very hard The introduction of 3D printing into the manufacturing of ceramic components offers entirely new possibilities for addressing the above-mentioned problems and challenges. The 3D printing of ceramics was first reported by Marcus et al. [3] and by Sachs et al. [4] in the 1990s. To date, with the latest advances in materials science and computer. Ceramic 3D printing is the technology of choice for the manufacturing of functional prototypes. We have also further developed 3D printing so that high-precision series production is also possible. We have therefore established ourselves as the market leader in industrial 3D printing. 3D Printing News 5 minutes read Introducing Alumina 4N Resin, an Accessible Technical Ceramic 3D Printing With Extreme Performance Watch on Formlabs is proud to announce Alumina 4N Resin — the first accessible, affordable, high-performance technical ceramic 3D printing material for stereolithography (SLA) 3D printers .

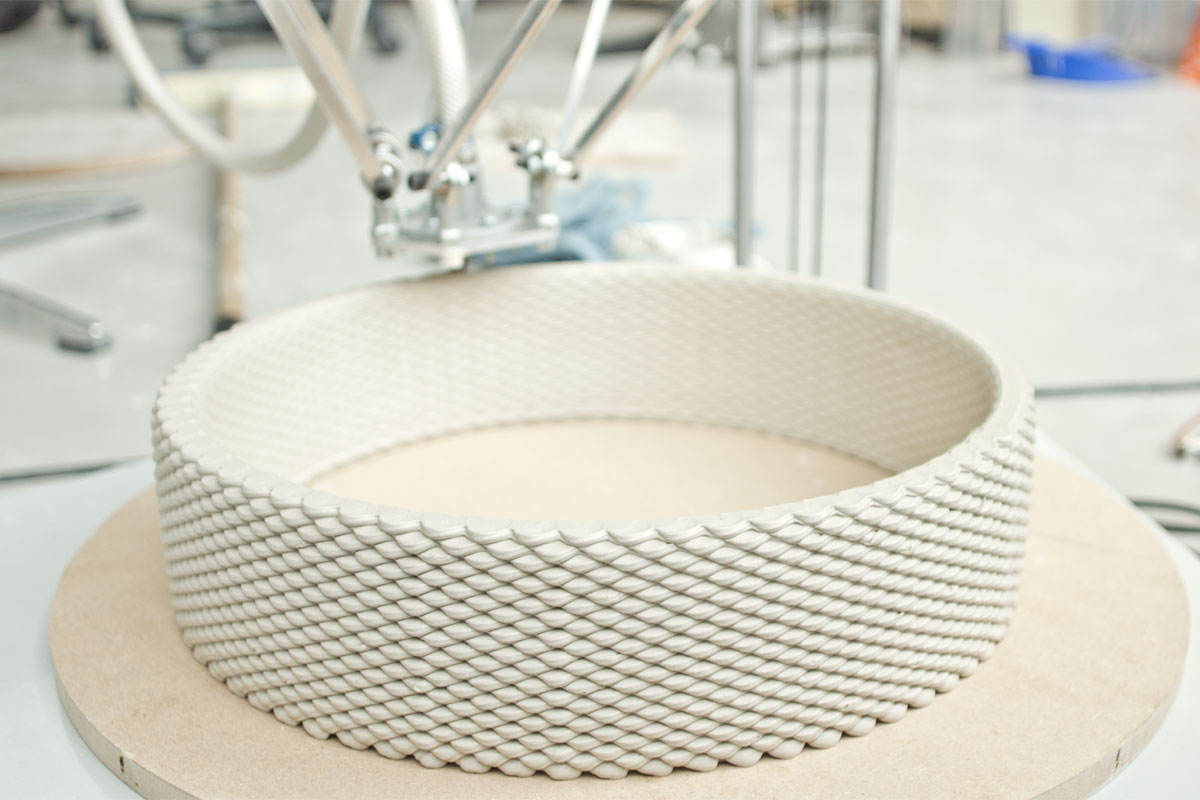

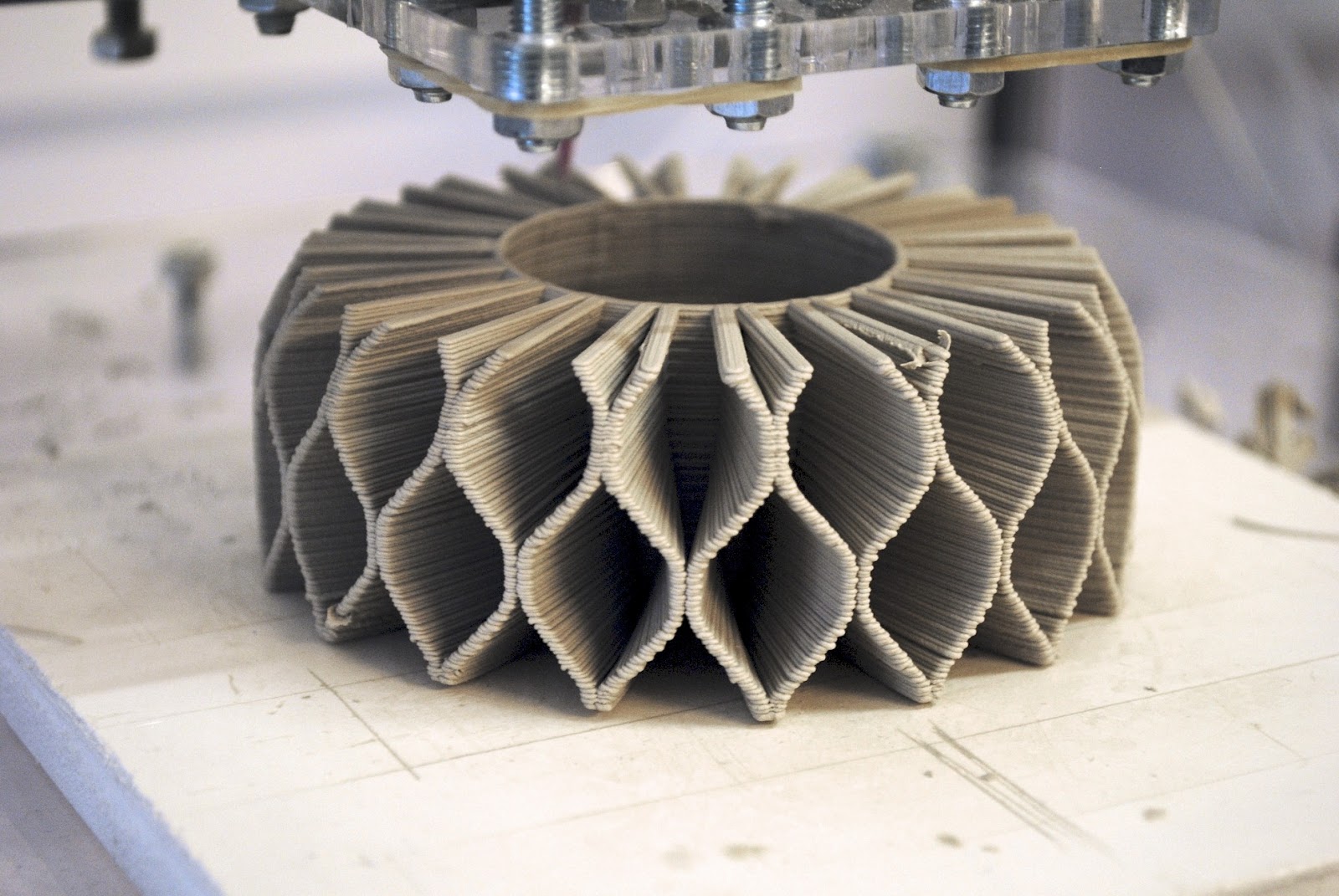

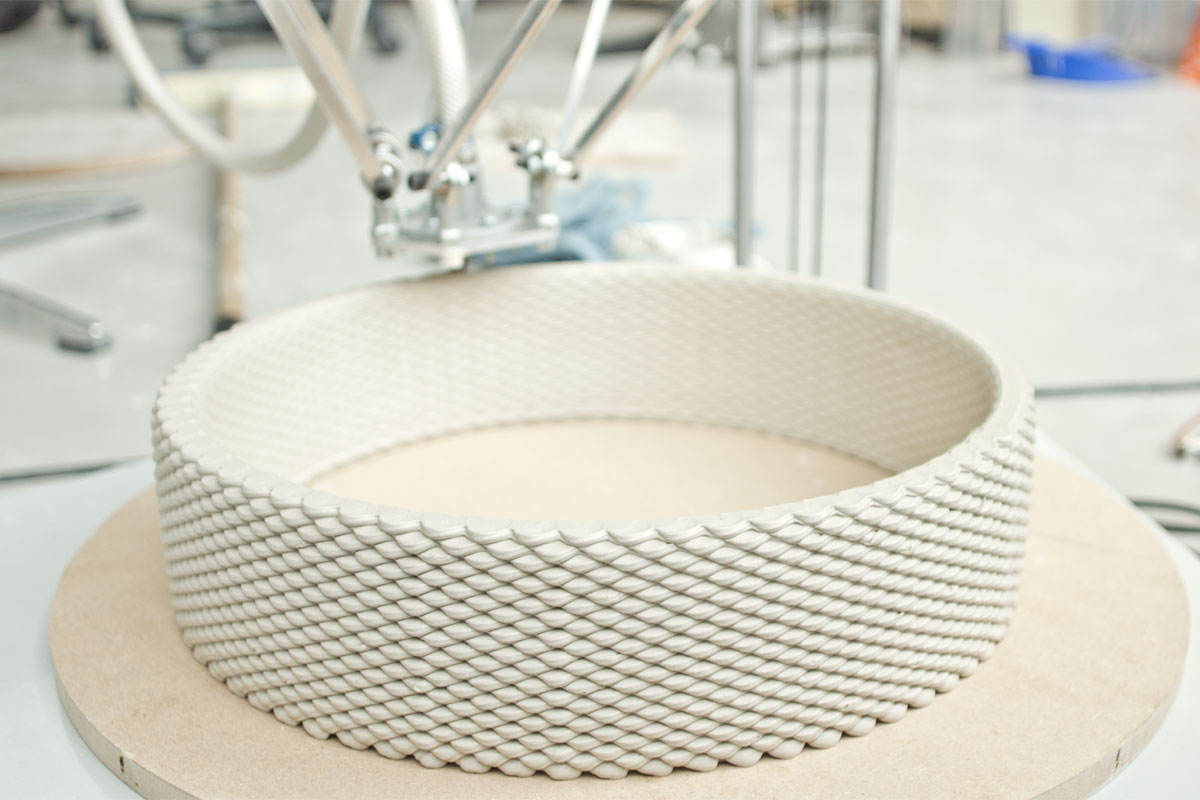

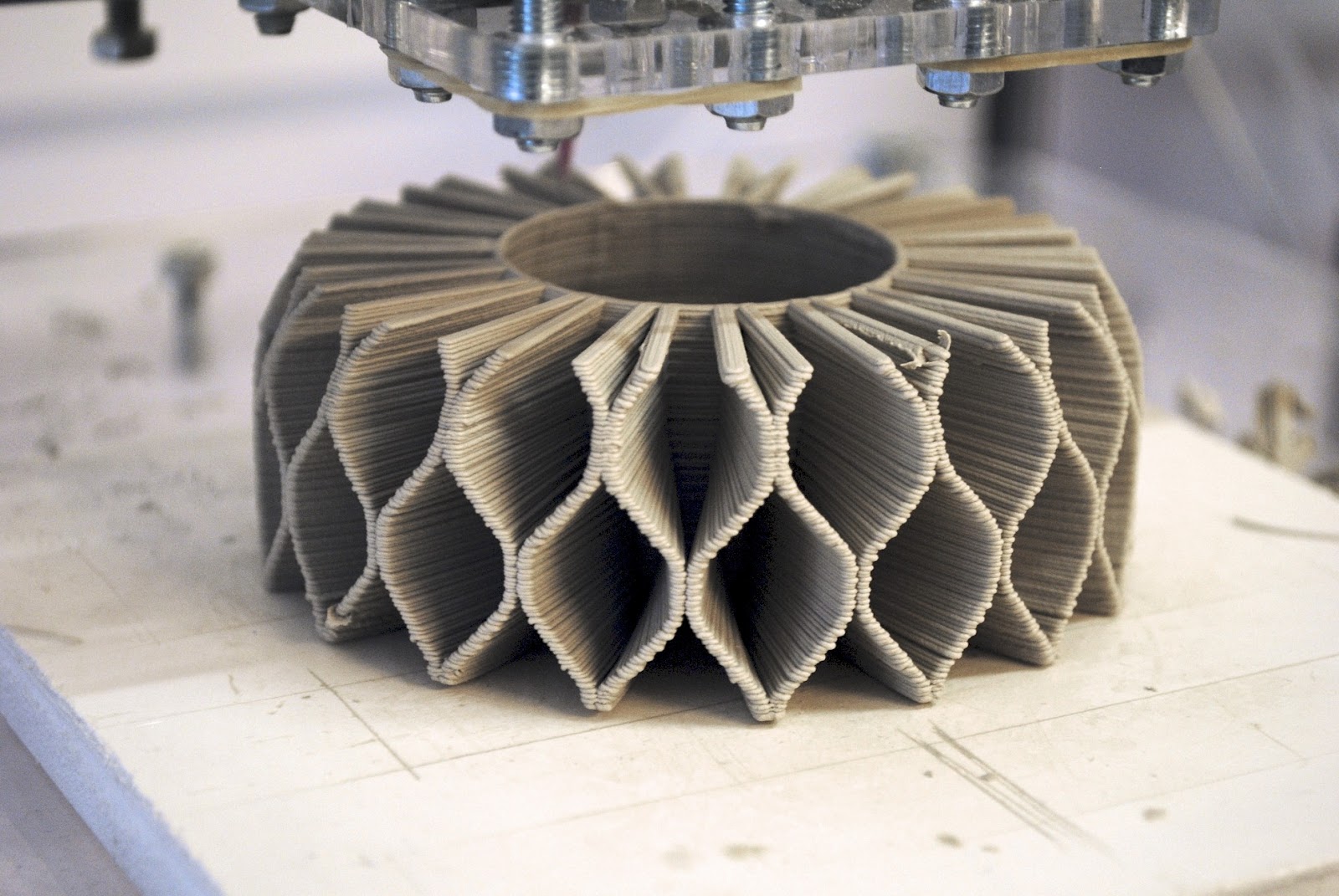

Functional 3D Printed Ceramics Olivier van Herpt

Ceramic 3D printing is a type of 3D printer technology specifically designed for the pottery industry. It allows ceramic artists to create pieces for museums and private collections using computer design software and prints them in clay on a 3D printer. 3D printing ceramics is a fascinating and rapidly developing technology that combines the precision of 3D printing with the versatility and durability of ceramic materials. Using printing technology for exotic materials like ceramic and metal is now possible for many commercial applications. There is no doubt that the evolution of additive manufacturing techniques with ceramic materials is a fact. But like all other 3D printing techniques it is adopted in different ways in each industry. Just as the 3D printing of metals has found special acceptance in the aerospace or automotive industry, 3D printing of ceramics has to find its place. 3D Printing in our Ceramic materials gives your designs excellent temperature resistance, high strength and low conductivity. Another recent addition to our 'Strong & Durable' and 'Fine Detail' service, our Ceramic 3D printing service gives you an ideal material where you need Strength, Smooth surface finish and excellent temperature resistance.

The Perfect Architecture Company Architectural 3D Printed Ceramics in California

Industrial-grade printing technology is used to create ceramic prints. The printer builds a 3D model, from bottom to top, one layer at a time. First, the printer's rolling mechanism spreads a thin layer of ceramic powder on a platform, and a print head places organic binder at specific locations. This is the first paper-thin layer of your model. Ceramics 3D Print Ceramic And Use Your Home Microwave As A Kiln Chinese ceramic printer company Cerambot has just announced the release of their new ceramic printer, dubbed the Cerambot Eazao, following on the success. read more » 3D Printers Intro to Ceramic 3D Printing

The 3D printing process also enables previously unthinkable geometries. Overall, ceramics will continue to gain importance as a material in the future, and the same applies to 3D printing as a manufacturing technology. As 3D printing empowers designers to push complexity in part geometry, new material possibilities are leading to true application breakthroughs. The Next 3D Printing Material Frontier. Used in construction for centuries, ceramics have evolved into cutting-edge manufacturing materials. Silica sand, for example, is a ceramic used in metalcasting.

More ceramic printing from Unfold

3D printing of hard-wearing materials. At 3D Matters Limited we work with organisations to deliver the best 3D printers on the market capable of producing parts in ceramic and metal materials. Whilst 3D Matters is primarily a technology hardware and materials provider, we do offer project support in the form of our 3D printing services. The Global 3D Printing Ceramic Market size is expected to reach 797.9 Million by 2028, exhibiting a Compound Annual Growth Rate (CAGR) of 27.1% during the forecast period. The aerospace & defence segment accounted for a share of 39.7% in terms of value in the 3D printing ceramic market in 2020 and is projected to reach USD 172 million by 2025.