Combustion Engine Cooling Water System (Jacket Water System) Online Course Article Introduction All internal combustion (IC) engines ( four stroke and two stroke) require some form of temperature control in order that they do not overheat and seize. Some engines are air cooled whilst others are water cooled. Water Jacket Passages - YouTube © 2023 Google LLC From a great question about water jackets and cylinder head gaskets.VIDEO SEARCH - https://the-workshop.net/STICKERS here -.

Coolant in Engine Block and Cylinder Head Water Jackets ASE Certification Training HQ

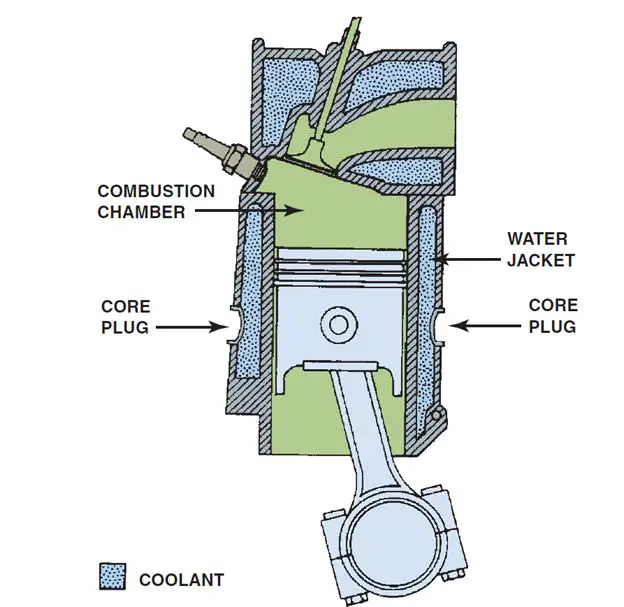

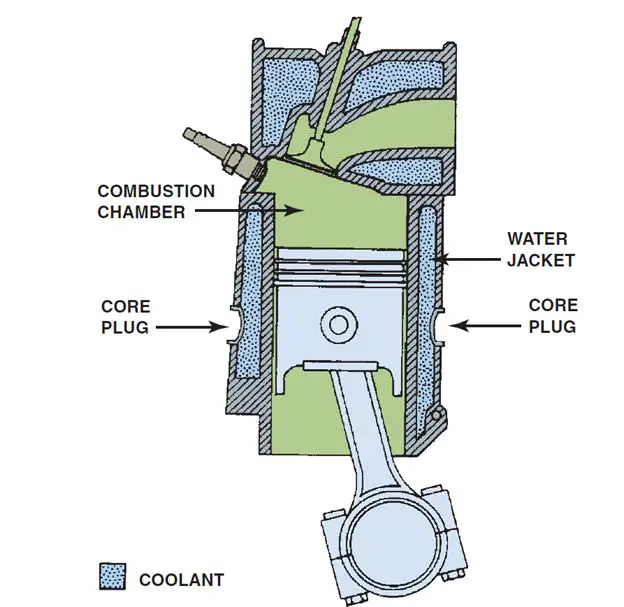

. the cylinder head water jacket, the cooling water flowing into the cylinder head water jacket from the body water jacket through the upper water hole is divided into two paths. Water cooling system mainly consists of: -Radiator -Thermostat valve -Water pump -Fan -Water Jackets -Antifreeze mixtures Various types of water cooling systems are given as; (a) Thermo-syphon cooling (b) Forced or pump cooling (c) Cooling with thermostatic regulator (d) Pressurised water cooling system (e) Evaporative cooling For most diesel engines, a jacket water discharge temperature of about 180oF is preferred with a temperature rise through the engine in the range of 8 to15oF. 6.1.1.2 Engine Coolant - Water is the most common coolant used in diesel engines. However, water alone presents the possibility of corrosion, mineral deposits, and freezing. A water cooling system for a slow-speed diesel engine is shown in Figure above. It is divided into two separate systems: one for cooling the cylinder jackets, cylinder heads and turbo-blowers; the other for piston cooling. The cylinder jacket cooling water after leaving the engine passes to a sea-water-

Combustion Engine Cooling Water System (Jacket Water System) Explained saVRee

In the enclosed system, the water that flows through the engine's water jacket and ports is the fresh water and coolant. The only part the raw water flows through is the heat exchanger. The same scaling occurs however. Jacket water cooling of main engine on ships has to be carried out in order to lower the temperature.Components of the This JW Cooling system are cooler, two. Jacket cooling water system. marine. The jacket cooling water system is used for cooling the cylinder liners, cylinder covers and exhaust valves of the main engine. Download scientific diagram | Coolant temperatures at the inlet and outlet of the engine water jacket. from publication: Revising engine heat transfer | Heat Transfer and Engines | ResearchGate.

3 Internal Combustion Engines cooling and lubrication system (automobile engineering)

marineinsight 177K subscribers Subscribe Subscribed 2.3K Share 129K views 3 years ago Marine Engineering and Technology #shipengine #jacketcooling #marineengine #enginecooling The Main engine. 1 Below Fig shows a typical jacket water system for marine diesel engines. Header Tank/ Expansion Tank: Expansion tank having mainly three functions storage fresh water, Maintain constant head and allow for the expansion/contraction of the water as its temperature changes. It is also known as a Make up water tank. Air Separator/ De-Aerator:

The characteristics of boiling heat transfer coefficient of a single-and two-phase flow heat transfer in a diesel engine water-jacket are investigated by Mohammadi et al. [12] [13][14]. They used. Received: 09 May 2021; Accepted: 16 August 2021. Abstract: The STAR-CCM + software is used to investigate the flow inside a cooling water jacket of an in-line six-cylinder diesel engine. The results show that the average flow velocity of the cooling water inside the jacket is 1.669 m/s while the flow velocity distribution is not uniform for.

12. The generator arrangement in the engine jacket cooling water system. Download Scientific

Engine Jacket Cooling Water Systems (JCW) are used for providing process cooling water to engine jackets to prevent damage to the engine; typically in power generation and Cogen applications. Typical system layout consists of recirculat ing pumps, heat exchangers, air separation/expansion control, and integrated temperature controls. 3 Table of Contents Contents 1.0 Cooling System Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8