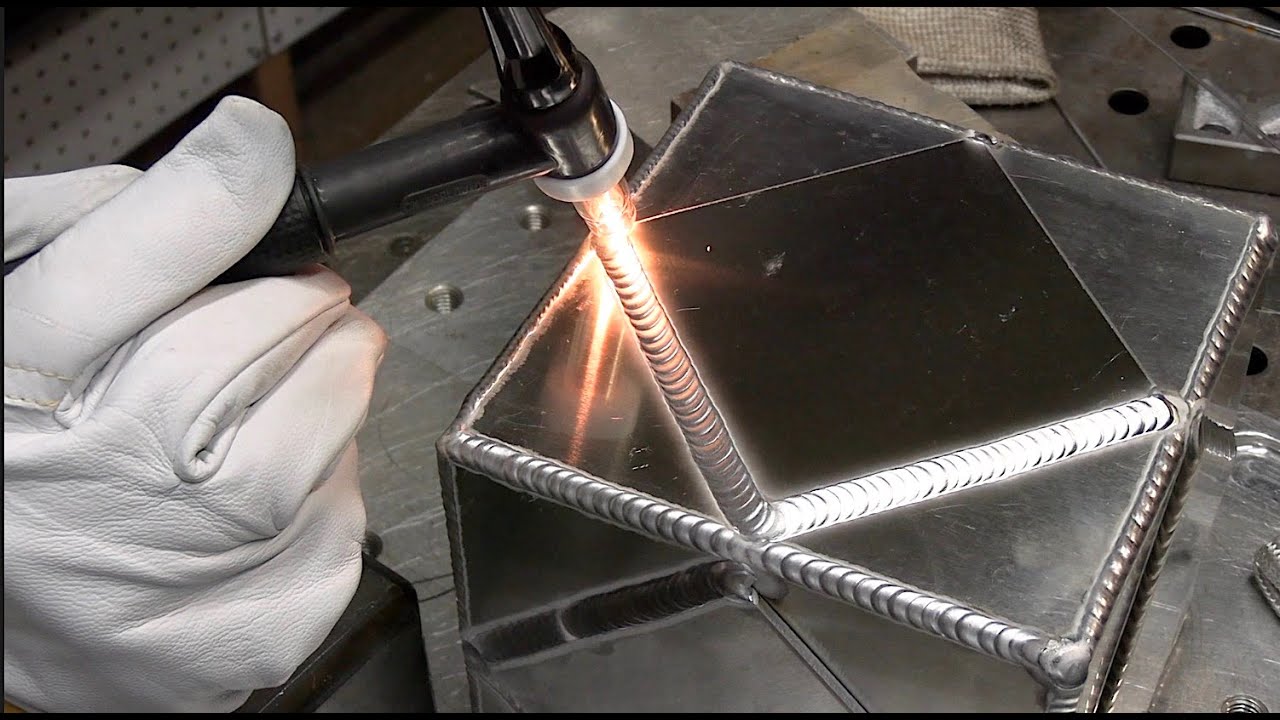

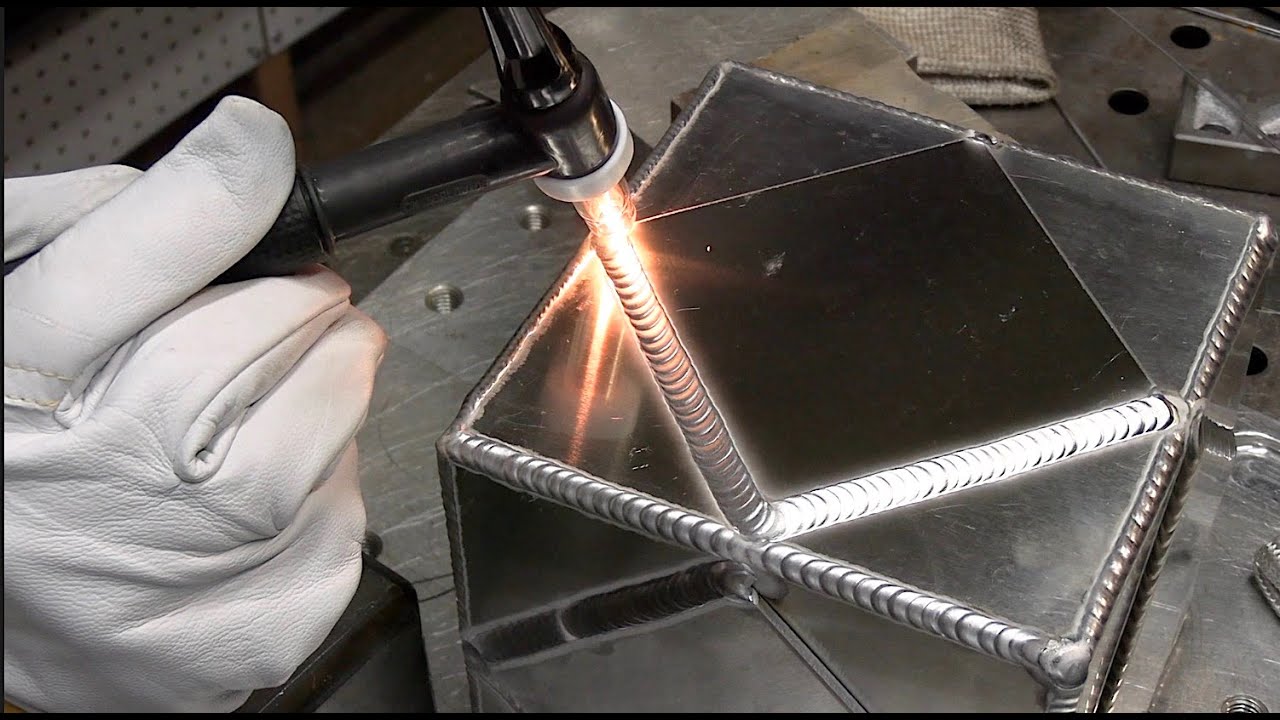

Step 1: Watch hand and torch placement Beginning TIG welders often unintentionally produce a lot of scrap because they don't practice basic hand placement and control before striking an arc on the base material. Aluminum acts like a big heat sink and rapidly transfers heat away from the weld area, which makes puddle control crucial to success. A comprehensive explanation to get you started with TIG welding aluminum. Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) or Heliarc.

11 Tips for TIG Welding Aluminum with DC Welding Mastermind

TIG (GTAW) welding is one of the cleanest and best ways to weld aluminum. TIG welding allows maximum control over every aspect of the welding process, resulting in high-quality, clean weld beads that look amazing. The issue with TIG welding aluminum is that it can be daunting for beginner welders. Shop the Justin Voss store #tigwelding #howtotig #aluminumtigweldingIn this guide I try to walk you through every step to get started practicing your aluminum TIG welding.Thank you to. Welcome to this beginner's guide on How to TIG Weld Aluminum! In this video, we'll walk you through the basics of TIG welding aluminum, including the equipment you'll need, safety tips,. During aluminum welding with the gas metal arc welding (GMAW) process, filler metal is fed into the puddle as soon as the welder squeezes the gun trigger. These "cold starts" can result in lack of fusion and insufficient penetration.

TIG Welding Aluminum YouTube

New to TIG welding aluminum? Learn how to start your arc, establish the weld puddle, and manage your current with this quick, practical how-to.Andy Weyenberg. 5 tips for TIG welding aluminum 1. Clean everything scrupulously. TIG welding aluminum requires that everything be squeaky clean, and this is particularly important with aluminum. Any trace of oil can cause porosity and may inhibit the flow of molten metal. I recommend getting in the habit of using a degreaser, since even the invisible oil from. How to Weld Aluminum like a pro with TIG, MIG & Stick Welding Last Updated On October 15, 2023 by Sandeep Kumar Learning How to Weld aluminum is not as difficult as it may seem. In fact, with the right welding filler wire rod, technique and a little practice, anyone can learn to weld aluminum. Therefore, beginners need to follow some steps and tips to master the art of TIG welding aluminum. I. TIG Welding Aluminum Steps. Step 1: Choose the Right Equipment and Materials. The first step to TIG weld aluminum is to choose the right equipment and materials for the job. You will need: A TIG welder that can handle AC (alternating current.

Aluminum TIG Welding Basics for Beginners How to TIG Weld Aluminum YouTube

Preheat Your Workpiece: It's a general practice that aluminum is preheated before performing any welding operation. This is because it makes the joining work a lot easier. Using any propane torch or putting it inside an oven could be enough. Just make sure it reaches 300 to 400 degrees Fahrenheit at least. Setting up the TIG welder for Aluminum will require you to go through the following steps: Choosing the Right Equipment (Right Type of TIG Welder) Selecting the Right Tungsten Electrode Cleaning the Aluminum Workpiece Choosing the Right Gas & Connecting the Gas Supply Adjusting the Amperage Adjusting the Alternating Current Balance Control

Arc welding processes work well for welding aluminum, but some are better than others. The TIG welding process offers the best aluminum joining method, while the MIG welding process has a speed advantage. Welding aluminum can quickly take a turn for the worse. All it takes is one mistake, and there are many parts of the welding process that. December 28, 2022 | 12:11 pm Tig welding aluminum with tungsten is a great way for welders of all levels to get the job done. In this blog post, we'll discuss why tungsten is such an ideal metal for welding aluminum and provide tips on safely and effectively creating a strong weld.

How to Improve the Look and Quality of Aluminum TIG Welds MillerWelds

The torch should be held at a 5-15º backward tilt and moved forward steadily. A close distance between the tungsten and aluminum workpieces must be maintained. The ideal distance is from the tungsten diameter up to around ¼" to prevent overheating and a loss of puddle control. 2. Smooth Movement and Filler Deposition. For best results, use an AC/DC TIG welder when welding aluminium. Ensure you also have the correct consumables fitted in the torch, suitable for aluminium. Select the correct welding parameters. As a general rule, it is advisable to use 1 amp per 0.001 inch material thickness. However this reduces when material thickness is over 1/4 in.