Metal Laser Cutters - The Ultimate Guide by All3DP Updated Aug 31, 2023 Metal laser cutting machines have become easier to use, safer, more flexible, and more affordable. Read on to learn how to make the best laser cutter purchase for your shop. Advertisement with personalized ads Accept and continue Laser Cutting Metal | Stainless, Aluminum, Titanium | Accubeam Laser Custom laser cutting metal services from Accubeam Laser Marking are beneficial for multiple industries. Learn more about our capabilities.

Precision Sheet Metal Laser Cutting Services PA Yoder Industries

John Abraham updated May 16, 2023 Laser Cutting Metal: Expert Guide [2023] Laser cutting is an effective way of producing high-precision, intricate cuts in metals. Despite the high density and strength of metals, an appropriate laser can cut through them by vaporizing them almost instantly. Laser cutting: the definitive guide to precision cut metal January 30, 2020 Laser cutting may seem like a futuristic innovation only fit for a laboratory. It is actually a thriving industry, with the market for these machines expected to grow to $5.7 billion by 2022. Any industry can benefit from using a laser cutting machine. Metals Supermarkets offers laser cutting from 0.5mm - 20mm thick, in all the materials listed above. Advantages of laser cutting Speed: Once programmed, parts can be cut in a matter of seconds, much faster than the alternative methods of plasma or waterjet cutting. Laser cutting is a contactless cutting method that uses a laser beam to melt or evaporate the target area. Cutting Cutting is when a material is fully sliced through to separate it. For example, cutting a steel blank into two slabs. Ask KEYENCE What Lasers Are Used for Cutting? CO 2 Laser

Laser Cutting Trends for 2018 Adopted by the Top Toronto Fabricators Weldflow Metal

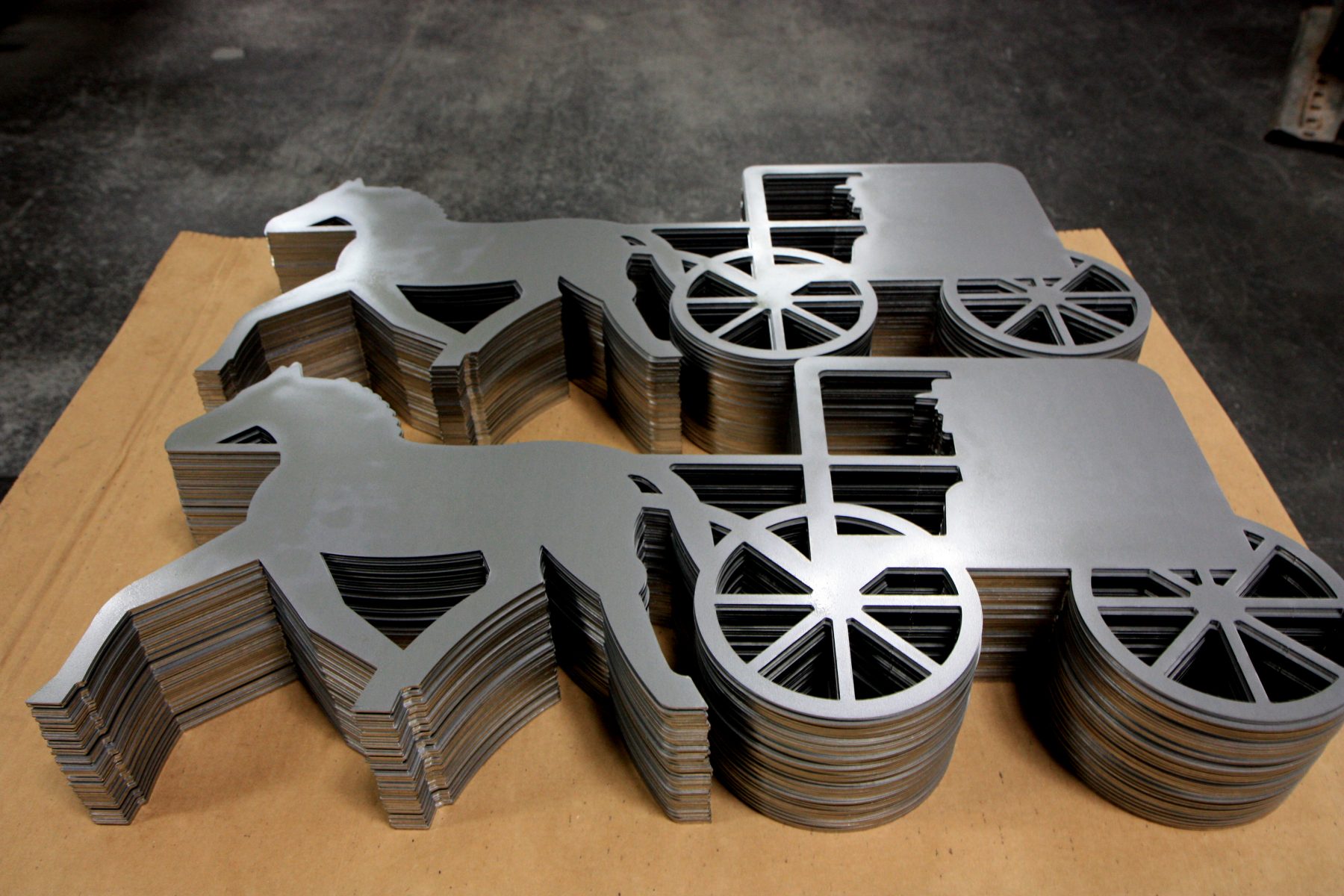

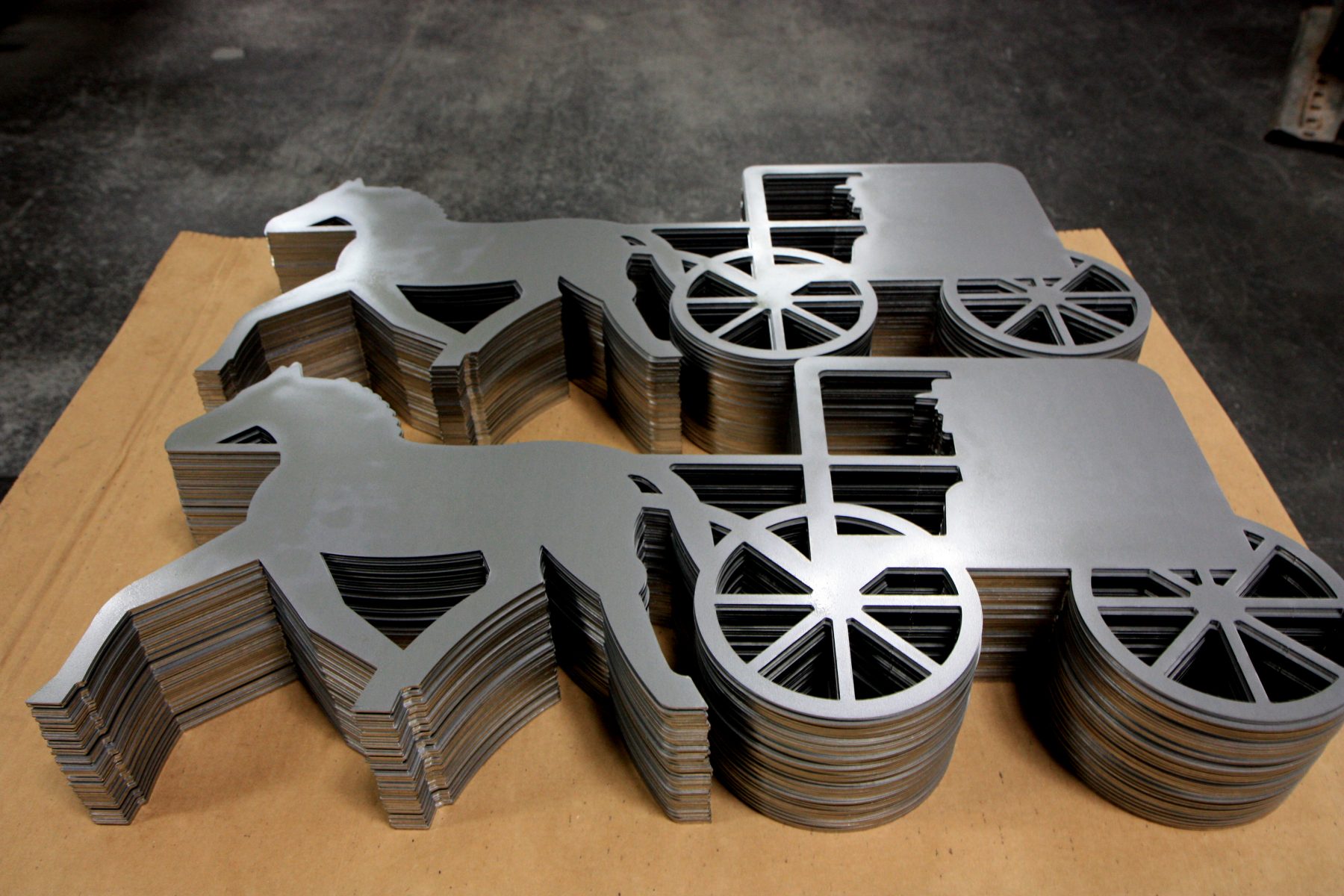

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. Give us a call at 801-850-7584 and we'll be glad to help. We are a direct metal cutting service, with no fabrication brokers or 3rd-party service providers between you and your parts. That means better prices, better customer support, and better lead-times. Online laser cutting has never been easier. TRY OUR ONLINE PLATFORM Laser cutting is a manufacturing process where a laser beam pierces raw sheet stock to produce flat geometries. A range of metals are available, which work well for components such as washers, mounts, brackets, and housings. Laser cutting is commonly used for: prototyping designs or testing product requirements efficiencies of scale up to 50+ parts Custom Laser Cutting Metal Parts. If you need thin metal laser cut parts, Micron Laser Technology has the capability to cut a variety of metals in a range of thicknesses to accommodate intricate designs and features. We specialize in the laser cutting of flat sheet metal, foils, or rollstock from .0005" to .5" in thickness.

Precision Sheet Metal Laser Cutting Services PA Yoder Industries

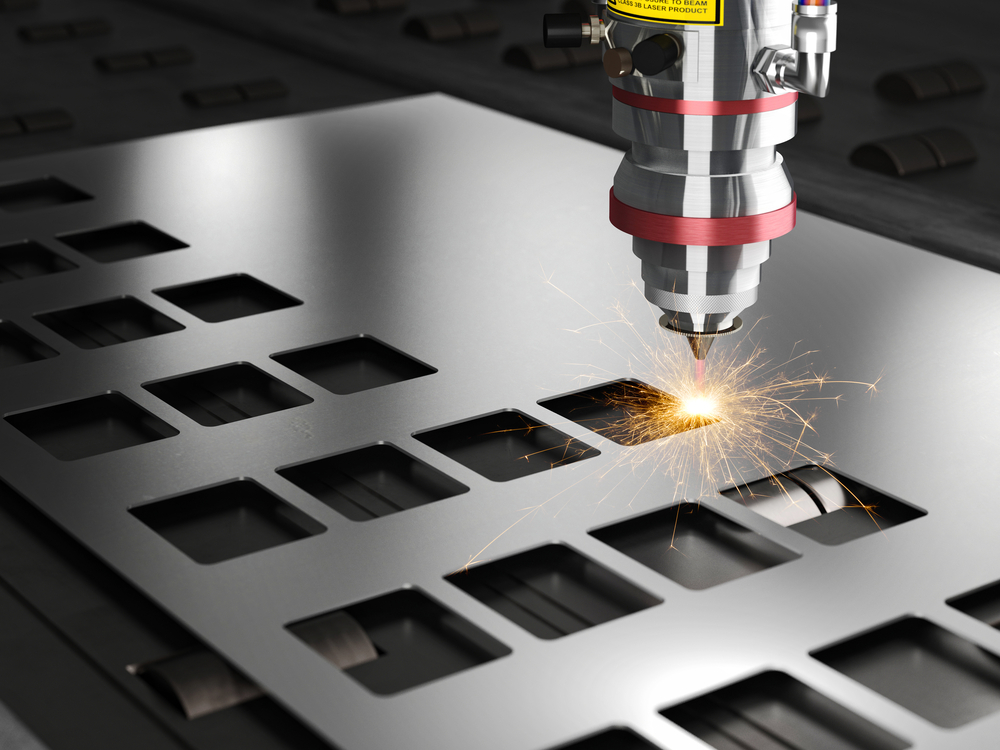

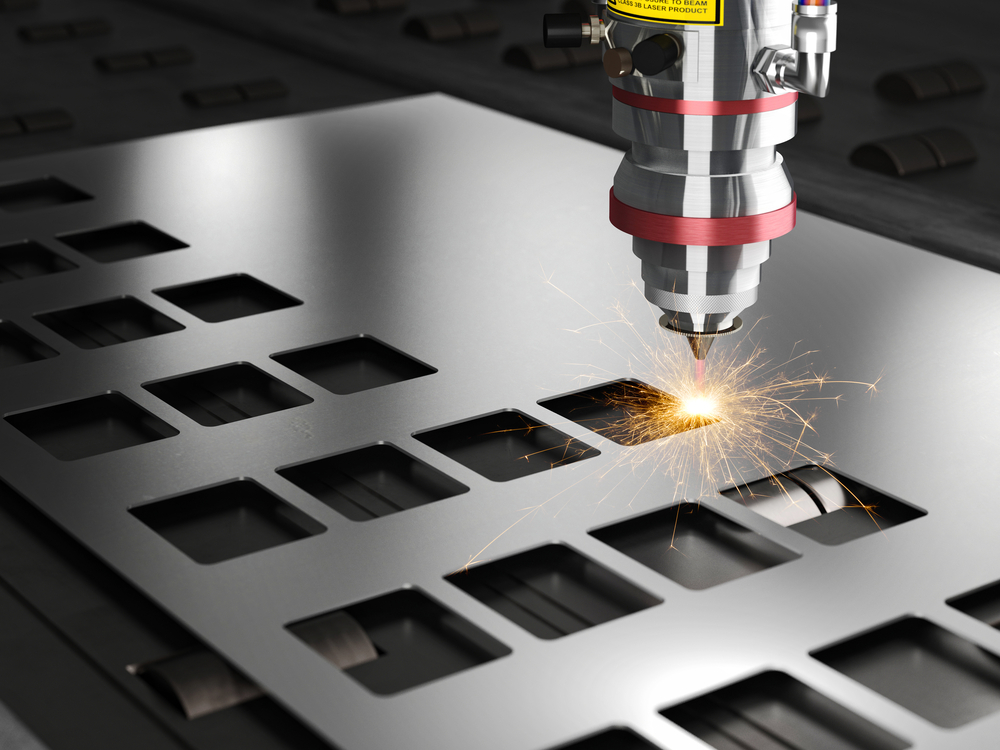

Laser cutting fabrication uses a high-power beam of light (laser) to cut out flat and thin sheets of metals. The process is directed by optics and computer numerical control (CNC) technology, which accounts for the high precision of laser cut parts. History of Sheet Metal Laser Cutting BOSS METAL CUTTING MACHINES Boss fiber laser cutting machinery utilizes the highest quality manufactured power sources for either of its pulsed or CW (continuous wave) cutting lasers. A fiber laser's power, wavelength, spot size, beam quality and power ranges are the basic parameters that modify the fibers cutting dynamics.

Laser cutting of metal is a process of heating and destroying metal with a laser beam. This technology is called Laser Beam Cutting (LBC). Modern lasers are able to cut metal 0.2 mm - 40 mm thick. The metal cutting technological process includes several steps: Focusing of the laser beam at a given point of the processed metal. Online laser cutting services made easy Upload your CAD file We accept DXF, EPS, DWG, AI, STP & STEP and files. Get an instant quote Prices include materials, cutting, deburring and free shipping anywhere in the USA, $19 to Canada Standard orders out the door in 2-4 days or less 1-3 day shipping on all standard orders No CAD File? No Problem!

Get the right machine for Laser Cutting

The short answer is that you can use a CO2 laser cutter or a fiber laser cutter for processing most types of metals (ferrous & non-ferrous) In addition, crystal laser cutters can be used to cut thick metals, but they are usually more expensive. The preferred choice is the gas (CO2) or the fiber laser cutters. Very smokey. The TTS-55 by Two Tree's is a no-frills 5 watt diode laser cutter / engraver that's a good starting point for budget minded buyers. It's easy to use and produces nice dark.