The milling process in large commercial mills combines a number of operations that produce better quality and higher yield of white rice from paddy or rough rice. The modern milling process 1. Pre-cleaning When paddy comes into the mill, it contains foreign materials such as straw, weed seeds, soil, and other inert materials. Weighing of rice Did this page help you? Milling systems A rice milling system can be a simple one or two step process, or a multi stage process. Read more Milling by-products The main by-products of rice are rice husk or hull, rice bran, and brewer's rice. Read more Measuring moisture content

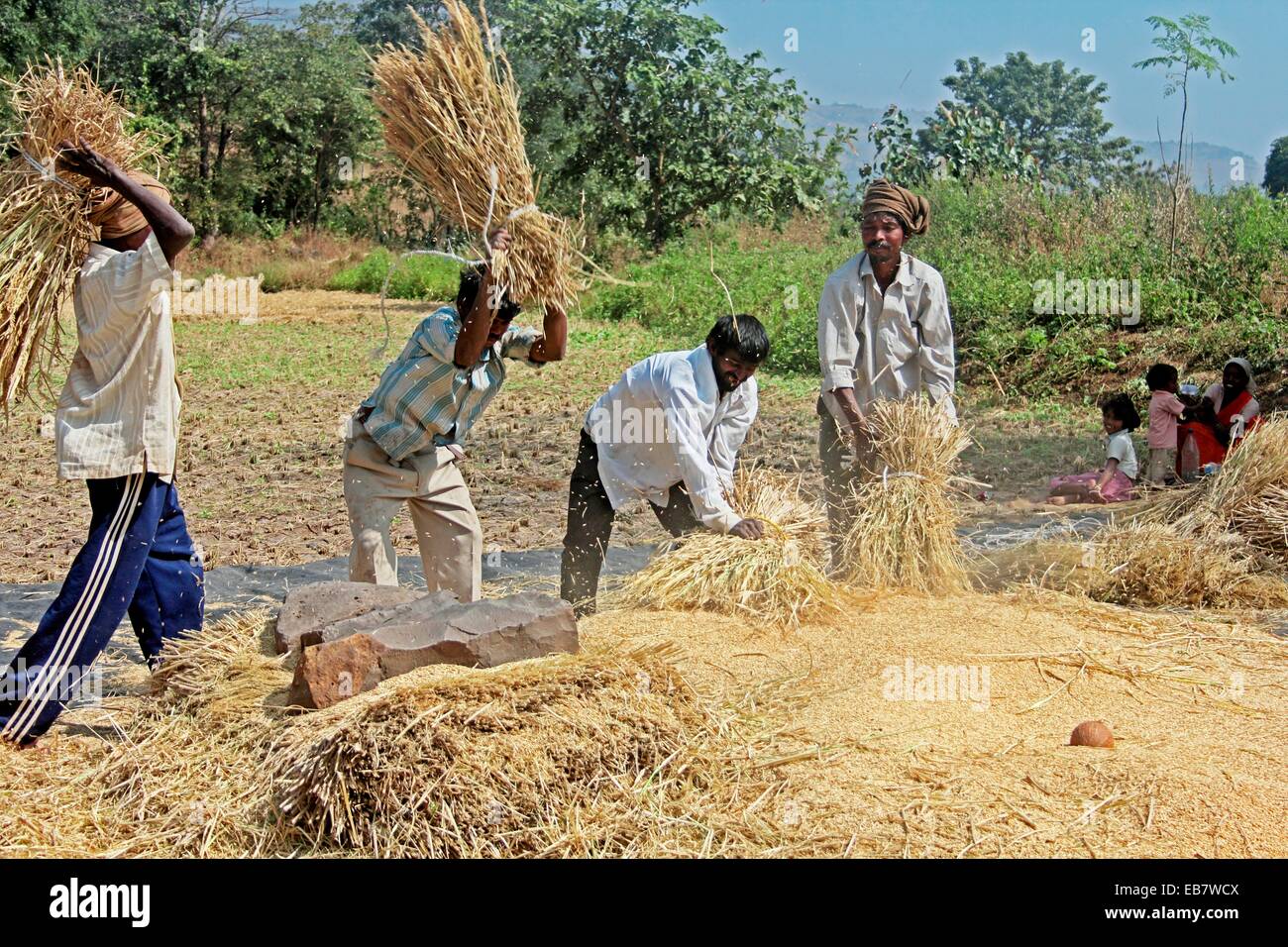

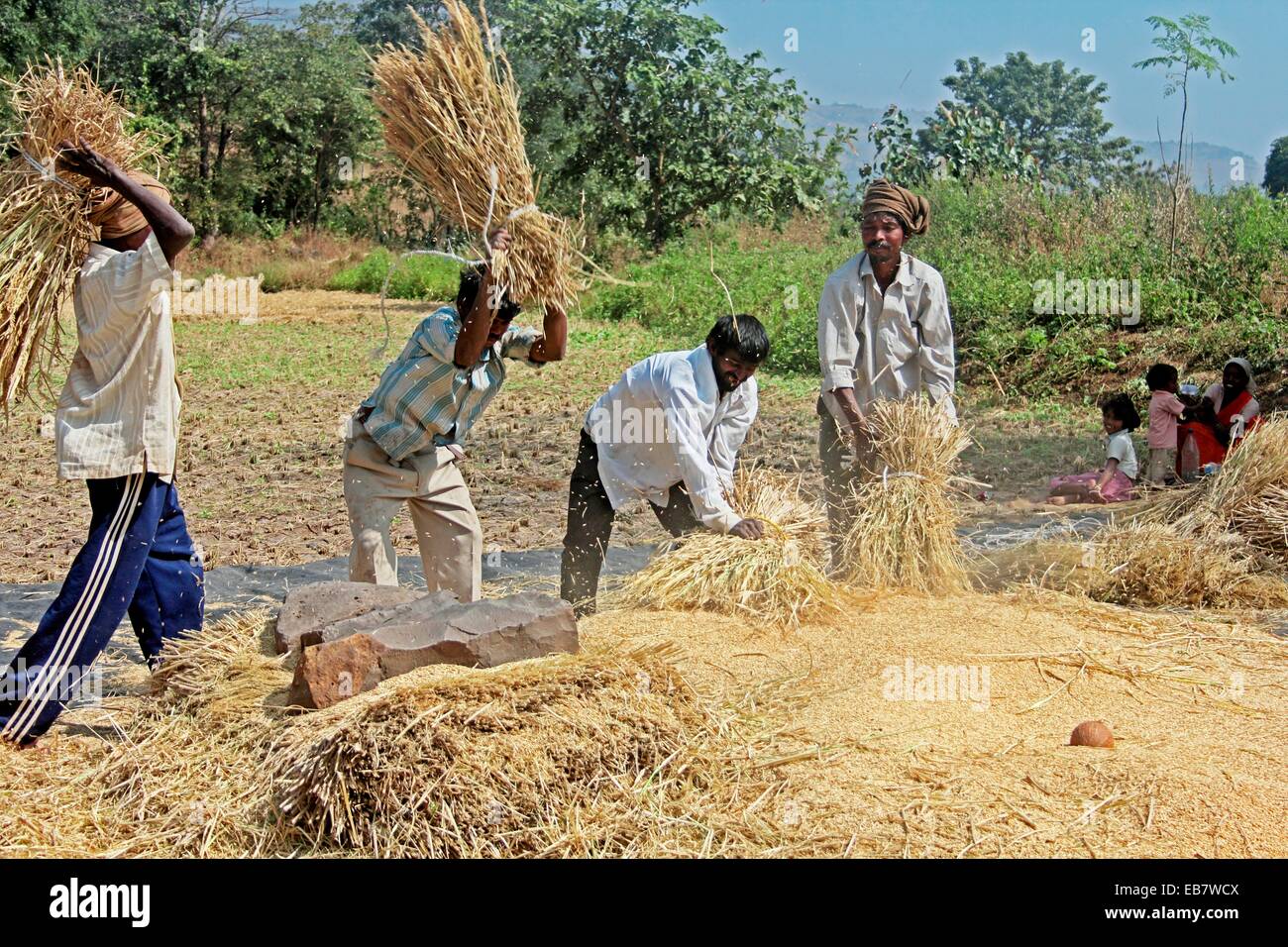

Harvesting paddy,Paddy Processing after Taken from Field, Threshing and winnowing Maharashtra

The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled, free of impurities and contain a minimum number of broken kernels. MILLING OF PADDY Traditional method is "Home-Pounding" Stages of Modern Rice Milling Process Cleaning: the removal of foreign matter Husking : shelling the husk from rice kernels Separating: husk, un-shelled and brokens Polishing: the selective removal of bran and germ from rice kernel Grading: the removal of broken grain form milled rice Impact of Parboiling Rice milling : process description Paddy Cleaning - Essential for removal of undesired foreign matter, paddy cleaning is given utmost importance to ensure proper functioning of the Rice Milling machinery. The h ydrothermal treatment prior to paddy milling is called as parboiling of rice. Parboiling is the process of boiling of rough paddy in hot wat er (70ºC) up to full soaking of paddy [2]. It.

Best sale cheap domestic rice husk milling machine,paddy pounder AWN 68 YouTube

Parboiling. Parboiling is a hydrothermal process that includes soaking, steeping and steaming, usually done to get parboiled white or brown rice. In soaking, the paddy is soaked either in normal or hot water for predefined duration. The soaking is the result of molecular absorption, capillary absorption and hydration. The paddy milling consumes significant quantity of fuels and electricity. The major energy consuming equipments in the rice milling units are; boilers and steam distribution, blowers, pumps, conveyers, elevators, motors, transmission systems, weighing, etc. Though, wide variety of technologies has been evolved for efficient use of energy for. Milling of paddy the major operation in paddy processing. It removes husk and outer layer of bran so as to produce acceptable white rice with minimum breakage and impurities. (The main objective of milling is to obtain maximum head rice Vitb-minimum breakage. Breakage of Rice milling is the process that helps in the removal of hulls and brans from paddy grains to produce polished rice. White rice is the result of further milling by machines that rub the grains together under pressure. This abrasion removes the bran layers, revealing "white" or "polished" rice. Rice milling machine is used.

Rice Mill, Paddy Machine, Paddy Husker, Paddy Peeler, Paddy Thresher China Rice Mill and Rice

Milling by-products. The main by-products of rice are rice husk or hull, rice bran, and brewer's rice. Rice husks or hulls are generated during the first stage of rice milling, when rough rice or paddy rice is husked. Rice bran is generated when brown rice moves through the whiteners and polishers. When paddy is hand-pounded or milled in a. The basic Rice Milling Processes consist of: Paddy Cleaning: Paddy cleaner is the most essential equipment in a rice mill, as it separates all the impurities like dust, straw, sand, clay and heavy particles of even an uneven sizes from paddy. The advantages with the paddy cleaner are that increases the life of rubber rollers and the percentage.

Rice Cleaning Process Removing the husk (dehusking or dehulling) Brown rice is actually produced by removing the husk from rough paddy rice. The husk is actually removed using friction so that paddy grains can easily pass in between two abrasive surfaces that move following different speeds. The hydrothermal treatment prior to paddy milling is called as parboiling of rice. Parboiling is the process of boiling of rough paddy in hot water (70ºC) up to full soaking of paddy [2]. It this work an attempt has been made to do the parboiling quicker. The soaking and drying are the long time consuming process, both are major barrier in

PPT Milling of Paddy Shelling and separation PowerPoint Presentation ID1046634

The State government had procured 92.34 lakh tonnes of paddy from farmers in the rabi of 2020-21. And at 67 per cent yield, it was supposed to deliver 62.59 lakh tonnes of rice but met only 58.92. The mill shall utilize the new SBT gunnies supplied with paddy stocks for delivery of custom milled rice. It shall return the leftover gunnies received with paddy after completion of custom milling. If not, the cost of the same will be collected at the 60% of the cost of the gunny. The mill shall maintain and furnish the detailed gunny account.