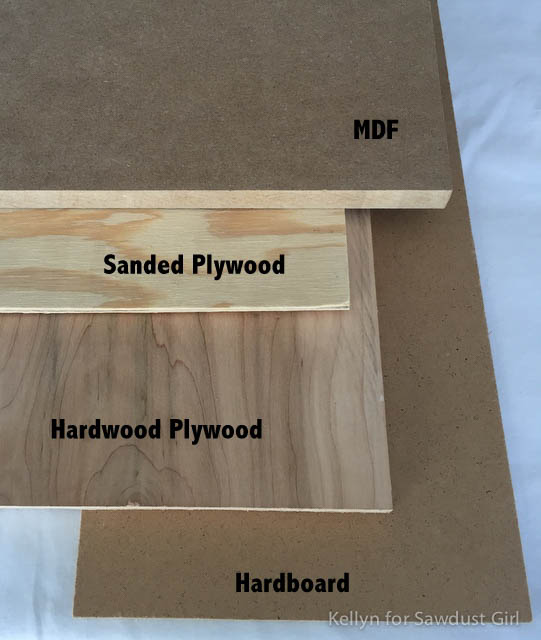

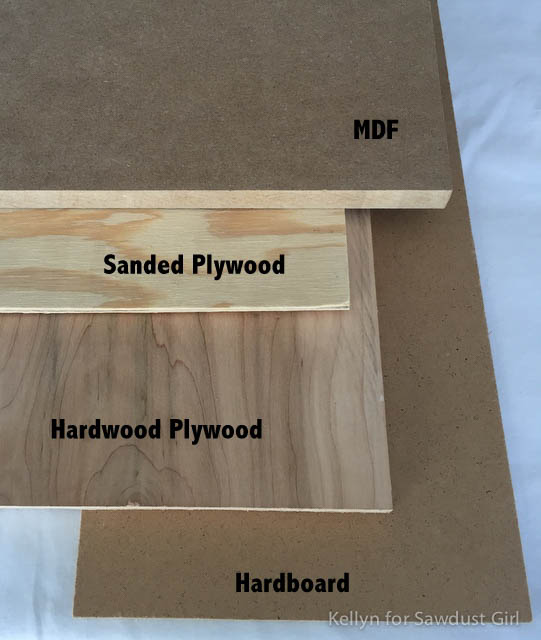

Consider the specific project requirements, such as strength, moisture resistance, surface quality, and budget constraints. Hardboard excels in structural applications, offering affordability, while MDF provides superior surface quality and versatility. Select the material that best aligns with your project goals and enjoy the benefits of using. The fundamental difference between MDF and HDF is the base ingredient. There is only one difference: the size of wood fibers used. Fine dust creates MDF, larger wood chips make HDF. The different base material creates all the other differences between the two board types. 2.

Selecting the right types of wood for your DIY project Sawdust Girl®

MDF vs Hardboard: The Conclusion. In the world of wood-based panels, MDF and Hardboard each have their own strengths and areas of excellence. MDF's versatility, smooth surface, and affordability make it a go-to choice for cabinetry, shelving, and furniture components. On the other hand, Hardboard's density, moisture resistance, and. Strength: HDF is the strongest, followed by MDF, while Particle Board is the weakest. Moisture Resistance: HDF is the most moisture-resistant, MDF is moderately resistant, and Particle Board is highly susceptible to moisture. Let's see the full comparison in a chart. Aspect. Price Comparison Between Hdf Vs. Mdf Board. While both HDF vs. MDF are used for similar applications to ensure the same durability, the construction of MDF is complicated, making it cost more than HDF. For example, you can get an entire sheet of plywood (25'x75″x3/4″) at wholesale prices less than $50, while MDF is almost 3 times as much. 7. Masonite Is Thinner. Masonite may be denser than MDF, but it is also a bit thinner. It takes a much thicker sheet of MDF to achieve the same strength when compared to Masonite. 8. Ease of Painting. If you are looking for something that is easy to paint and stain, then MDF is definitely the better of the two.

MDF vs HDF vs HDHMR Which is Better ?? (Full Comparison) YouTube

What is MDF? Sheets of MDF. MDF has a typical density of 680kg/m^3 to 730kg/m^3, but it can be as high as 800kg/m^3. As compared to HDF, it has more compact fibers that make it less likely to become 'furry' when machined. The furriness can make it difficult to use paint or primer on the product later in the process. It has a smooth surface and a high density. HDF (High-Density Fiberboard) and MDF (Medium-Density Fiberboard) differ in density as HDF has a higher density than MDF. Hardboard is made in a different way than HDF and MDF, with the wood being chopped and crushed to generate wood fibers and uses water as a flocculant from the wood fibers and binds. HDF is referred to as hardboard, a high density fiberboard (HDF) for flooring is a type of engineered wood product. It's made from wood fiber extracted from chips and pulped wood waste. HDF for flooring is similar but much harder and denser than particle board or medium density fiberboard (MDF) for flooring. While neither version does well around water, HDF is more water-resistant than MDF, and its density does also make it stronger. MDF, on the other hand, is much more suitable for furniture and decorative pieces. It's highly affordable, and has a smooth surface that lends itself well to being painted. Using veneer on MDF can also create the.

Differences between wooden boards MFC, MDF, HDF and Plywood

Advantage #1: It Is Quite Durable. As far as engineered wood products go (especially when compared to particleboard, fiberboard, and other related products), the hardboard is very durable. That is mainly due to its density and weight. It's stronger than most other types of engineered wood, and it has a great deal of impact resistance too. Quality and Cost…. When compared to MDF and particle board, hardboard has a number of great advantages like it's superior strength, durability, and water resistance. It can also be easier to work with. Unlike plywood and other fiber boards, hardboard is only sold in thin ⅛ inch or ¼ inch thick sheets.

Plywood. Plywood boards are made of overlapping wood sheets glued perpendicularly and heat pressed. Just as with cross laminated timber (CLT), cross-directional fibers in plywood allow the board. Additionally, Hardboard and MDF are the only two kinds of wood we currently offer in ⅛" thickness making it easily transferable to common metal thicknesses and applications. The material is also relatively light in comparison to Plywood or MDF (about half the weight) making it a good prototyping material for weight-dependent applications that may be transitioned to a lightweight composite.

Plywood vs. Hardboard Which Should You Use? Handyman's World

Hardboard has a hard smooth side and a soft corrugated side, and is not very strong overall. MDF is much more homogeneous, stronger, less compressible, and looks the same both sides. You have to define stronger. There are differences in flexural, compressive and shear strength. IMO, hardboard has better flex qualities. MDF typically has a density of 600-800 kg/m³, as compared to hardboard, which has a density nearly double that of MDF (1,450 kg/m³). HDF panels come closer to the densities of hardboard but are still normally 10 lb/ft³ lower in density than hardboard, making them more porous and more prone to warping, especially in a 1/8" thin version.