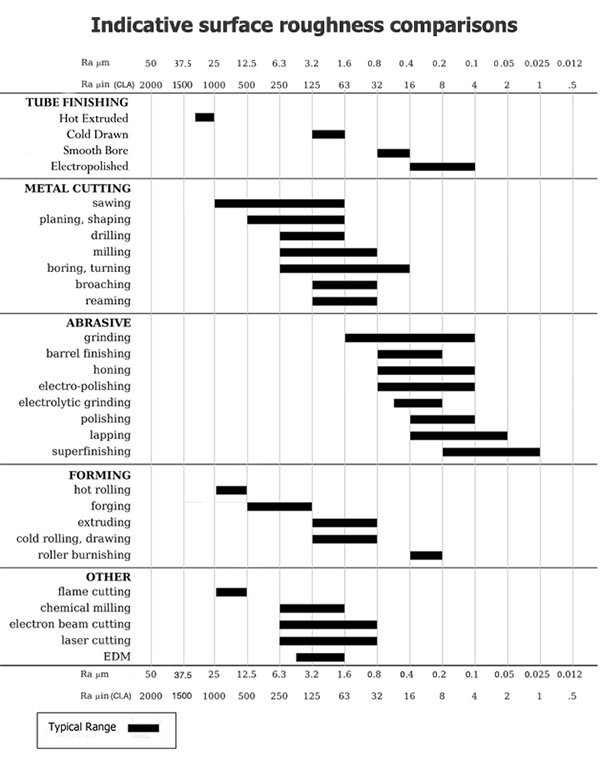

Surface Finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Surface Finish when it is intended to include all three characteristics is often called Surface Texture to avoid confusion, since machinists often refer to Surface Roughness as Surface Finish. Surface Finish and Surface Roughness Contents show The finish on a metal surface after machining depends mainly on the material and some are as follows. It depends on the structure of the metal before and after machining, Depends on cutting conditions such as type and degree of sharpness of the cutting tool, Depth of cut, Amount of feed,

PPT Surface Finish PowerPoint Presentation ID3866407

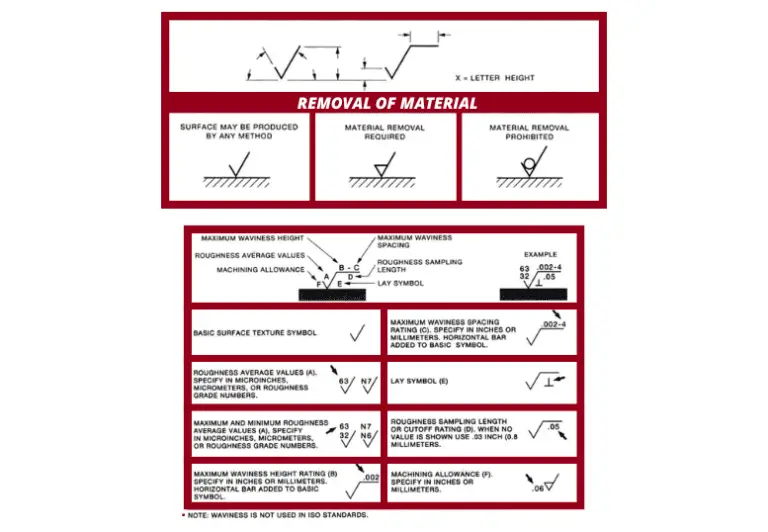

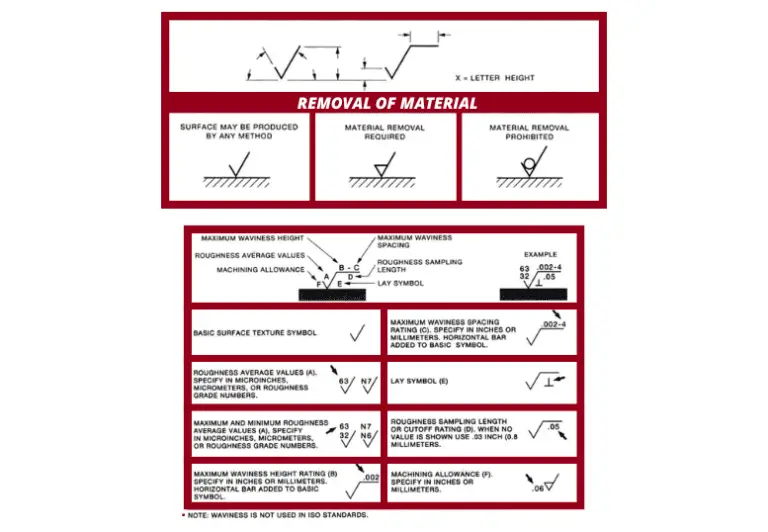

Surface finish is composed of three distinct elements - roughness, lay, and waviness (See Figure 1 below). However, it is not uncommon in machine shops for the term surface finish to be used to describe only surface roughness. Lay - The direction of the predominant surface pattern (often determined by the manufacturing process). Waviness - Pertains to fine detail imperfections or coarser irregularities, such as surfaces that are warped or deflected from specifications. Surface Roughness - A measure of finely spaced surface irregularities. A symbol for defining the surface finish of a part. There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface. Machinist also refers to surface roughness as surface finish. So what is Surface texture? Surface texture measures a surface's overall texture, defined by the surface's lay, surface roughness, and waviness. This graphic illustrates how to think about the link between Waviness, Lay, and Roughness: Surface texture characteristics What is Roughness?

Surface Finish Lay Symbols

a: Passband or sampling length and surface texture parameter symbol and value b: Indications of the second and subsequent parameters when multiple parameters are required c: Machining method d: Crease and its direction e: Machining allowance The descriptors shown below are used when pictorially representing surface roughness. Whenever machinists talk about "surface finish," they often refer to surface roughness. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Lay refers to the direction the predominant surface pattern takes. Machinists often determine the lay by the methods used for the surface. Surface Finish: A Complete Guide to Surface Roughness In Manufacturing May 13, 2022 Surface an important aspect of machined parts. The finish of a surface has a significant impact on the durability and performance of a product. So, it is essential to understand surface roughness and its role. What is Surface Finish/Surface Roughness? Definition and Importance of Surface Finish The surface finish is more than just a smooth touch or shiny look. It encompasses the texture of a surface, its roughness, waviness, and lay. These factors are not just for show; they play a pivotal role in determining the quality and functionality of machined parts.

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA

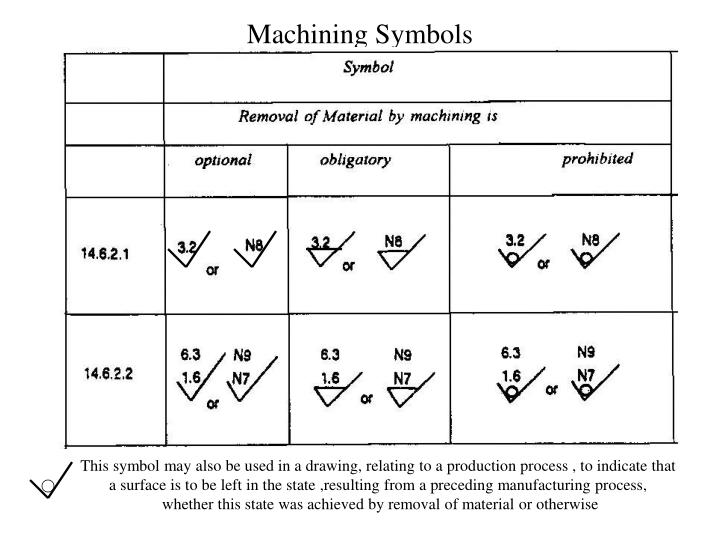

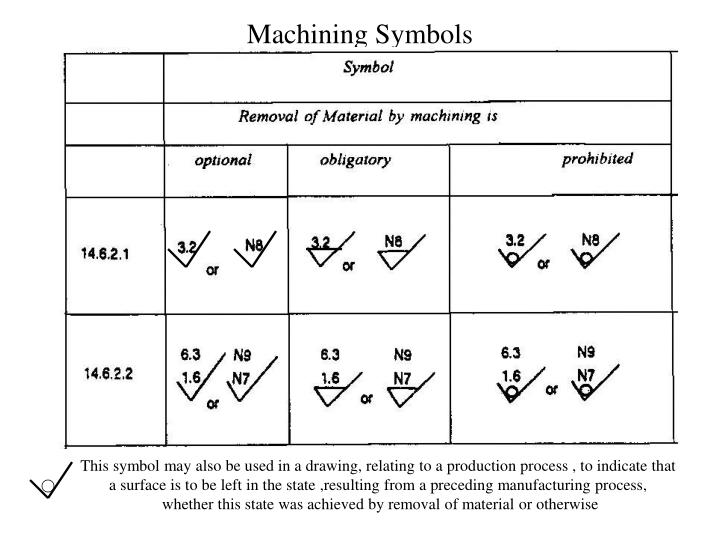

Learn more about: Surface Roughness Parameters for CNC Machining. Symbols and Abbreviations in Surface Roughness Chart. There is a variety of symbols and abbreviations simply explaining the parameter for surface finish, such as Ra, Rz, Rq, Rku, Rsk, and more.. Good machine finish: Production under controlled conditions: 0.8: 32: 1. Basic shaped roughness symbol. It is consists of two lines of unequal length inclined at an angle of approximately 60 degrees to the line representing the considered surface, the symbol must be indicated by thin lines. Surface texture obtained by any manufacturing process, such as CNC turning, grinding, bending, etc. 2.

1. As Machined As-machined parts are just off the production line and contain light tool marks, an average amount of surface abrasion, and a particular texture or completed appearance. According to the use case, a component's average surface roughness (Ra) is the difference between its real and ideal machining surface roughness. Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction.

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

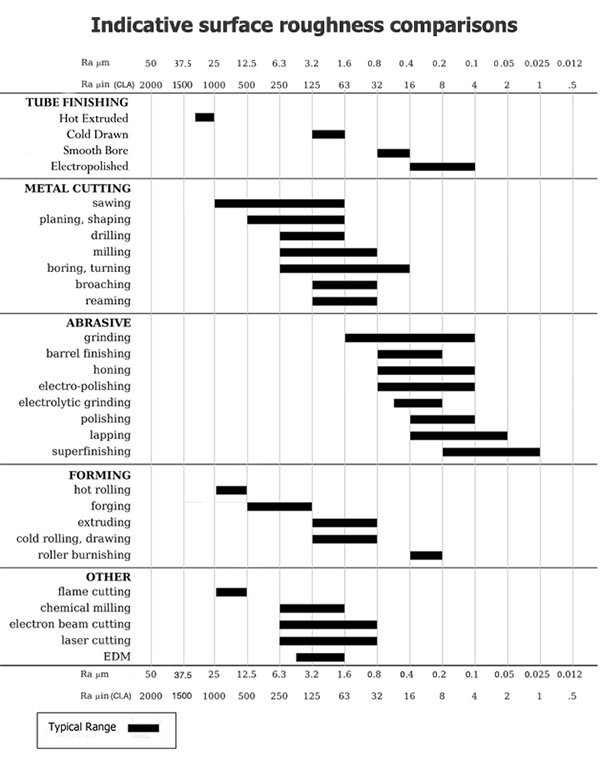

A surface finish symbol is a mark found on pieces that have been machined by either turning, grinding, or boring. Surface finish symbols are not the same across all industries. Surface finish specification and comparison. Finish Symbol N Finish R a μinch R a μm Super finishing: N1 1 0.025 Lapping. Machining N9 250 6.3 N10 500 12.5 Rough Machining N11 1000 25.