Step 1: Hardware Depending on the design you choose to make you can substitute parts with the ones you find locally. For example, you can switch the steel tubes/smooth rods with a Drawer slider, which can act as a linear axis. Plywood (12mm) Rails (Steel tubes, Smooth rods) Lead screw (M8 x 600mm, as long as you need the axis to be) Using the new Adafruit Motor Shield v2 and an Arduino UNO I'm showing how to control 4 stepper motors at once with GCode, the standard language for CNC machines like 3D printers, mills, and lathes. If you are designing your own machine this is the simplest way to get started.

Tindie Blog 4Axis Arduino GRBL CNC Shield

Using the Adafruit Motor Shield v2 and an Arduino UNO I'm showing how to control 4 stepper motors at once with GCode, the standard language for CNC machines like 3D printers, mills, and. GitHub - dguerizec/grbl-Mega-4axis: An open source, embedded, high performance g-code-parser and CNC milling controller written in optimized C that will run on an Arduino Mega2560 Sign in to GitHub Password New to GitHub? Terms Privacy Docs Contact GitHub Support Manage cookies Do not share my personal information dguerizec / grbl-Mega-4axis Public To create a CNC machine with Arduino, you will need: -An Arduino microcontroller -A stepper motor driver -Stepper motors -A power supply -A frame or base for your CNC machine Kindly note that these are just the basic electronic components we need to understand how a CNC machine works. 1. Frame or Base I set up the electronics with two Y axis motors and 2 Y axis stepper drivers for extra torque. You will need (see 0:59 in the video): RAMPS 1.4 board; Taurino board - based on Arduino but can handle higher voltage and current; RepRap wiring kit, with 1 metre wires. You can make your own cables, but the wiring kit is cheap and easy.

GRBL & Arduino How to Set Up and Get Started All3DP

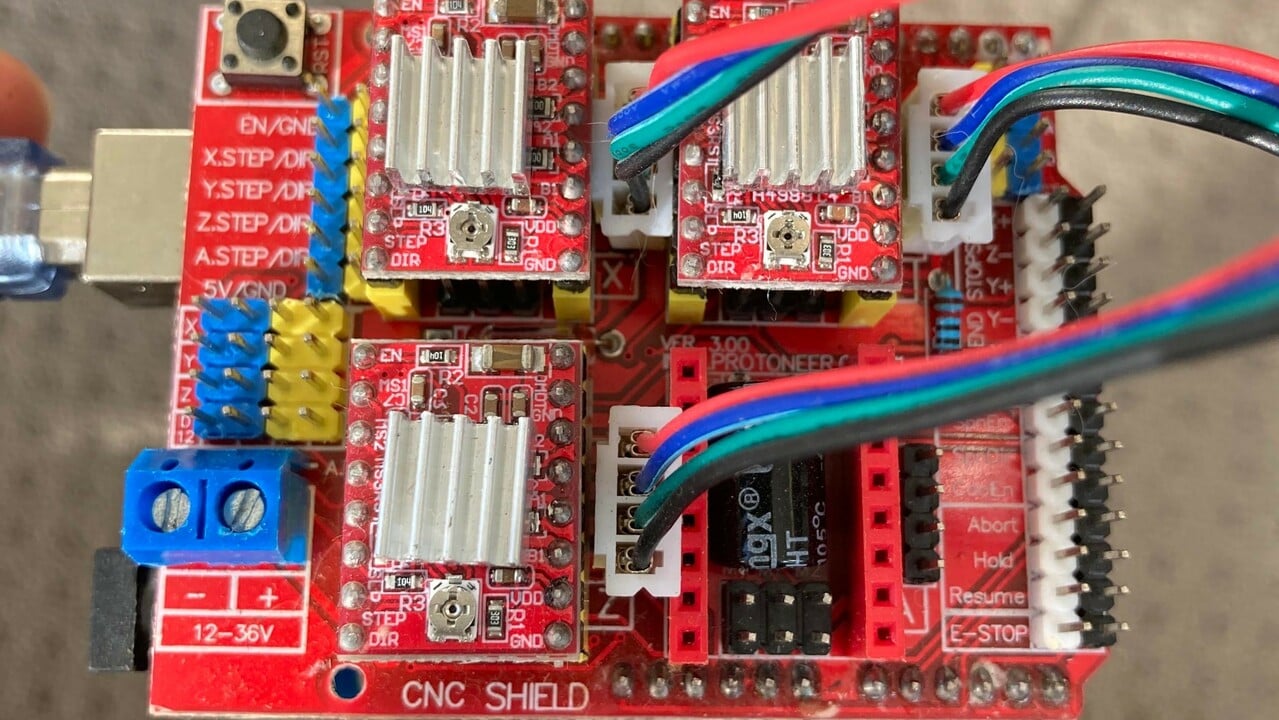

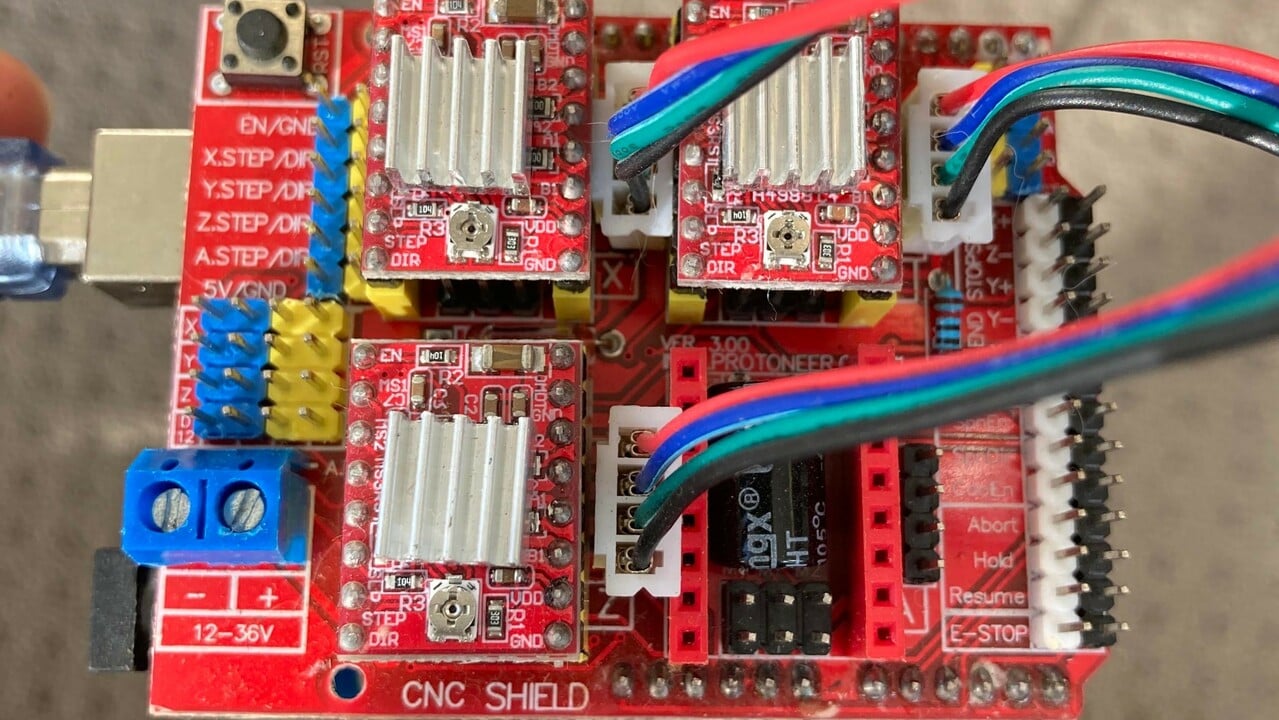

4-axis Arduino based CNC hot wire foam cutter Using Arduino Project Guidance sorenvedel June 15, 2015, 1:05am 1 Yesterday I tried to calibrate with the M92 command. // NEMA 17 with standard pitch M8 threaded rod: (400 * 16) / 1.25 = 5120 because my steppers are 0,9 degrees/ step = 400 per turn So i sent these two commands to my board: Description DRV8825 stepper motor driver compatible, 4-axis Arduino CNC Shield v3. Features GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals) Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others) ( Not Included) PWM Spindle and direction pins 4-Axis Arduino GRBL CNC Shield. February 8, 2018 ; Tindie; Jeremy Cook; When you decide to build your own CNC, choosing a controller is a big decision and there are a few different directions you can take. If you can find or modify a PC to output parallel port signals, you can control things directly. This is become far less common as finding a. A DIY 4-axis CNC hot-wire foam cutter using Arduino and Grbl for cutting RC wing Cores.The Frame is made from 1/2inch plywood and each axis is driven by a st.

ArduinoCNCShieldV34thAxisJumpers Protoneer.co.nz

Arduino CNC Shield - For connecting the stepper drivers to the Arduino, the easiest way is to use an Arduino CNC Shield. It utilizes all Arduino pins and provides an easy way to connect everything, the stepper motors, the spindle/ laser, the limit switches, cooling fan etc. Which was firstly adapted for 4 axis by Letartare, further improved by Skwee and adapted to work with the Ramps1.4 board by myself. There are currently new efforts to make 4 axis GRBL version based on the latest 1.1 version, but those are not finished yet. - GRBL HotWire Controller. The program is a modified version of Grbl-Panel, adapted by.

1512×2016 1.07 MB (5) DRV 8825 Drivers with Heatsinks Source: Ebay - many vendors some cheaper, I chose stepperonline. Price: $10.00 2202×1374 385 KB So for under $40.00 hopefully I will have a 4 axis capable machine running GRBL 1.1 and be able to run OpenBuilds Control software as a bonus. This shield goes on top of an Arduino UNO board, and can control up to 4 individual stepper motors, and have all the remaining Arduino pins available for use. I used this combination of an Arduino UNO board and the CNC shield for controlling my 4-axis SCARA robot arm.

4Axis CNC Hotwire Foam Cutter (Arduino+Ramps1.4) 9 Steps (with Pictures)

The first step is to include the library with #include . // Include the AccelStepper library: #include. The next step is to define the TB6560 to Arduino connections and the motor interface type. The motor interface type must be set to 1 when using a step and direction driver. You can find the other interface types here. If you have an Arduino, you can use it to control a CNC machine. Read on to find out all about Arduino CNC shields!