Octopart Is The Preferred Search Engine for Electronic Parts. Search Across Hundreds of Distributors to Compare Prices, Inventory and Save! Porcelain for a Tsar, a Maharajah or a King !

12v Automatic battery charger circuit and PCB Soldering Mind

This is a schematic for building a discrete transistor charger, which can be used to charge NiCd and NiMH batteries: This circuit is designed to charge a 12V battery at 50mA, but it can be easily scaled up to higher voltages and currents with suitable components. Prevent mistakes by downloading my DESIGN REVIEW CHECKLISTS for the schematic circuit, PCB layout, and enclosure 3D model design: https://predictabledesigns.. The battery charger circuit is designed around a dedicated lithium-ion battery charger TP4056 IC. TP4056 is a complete constant-current/constant-voltage linear charger for single-cell Lithium-ion batteries. Its SOP package and low external component count make the TP4056 ideally suited for portable applications. We are going to build a simple, low-cost USB powered single cell lithium polymer battery charger as a practical project. Many products integrate lithium polymer batteries. With their high energy density and a vast array of sizes and capacities, you can find the perfect battery to power your circuit.

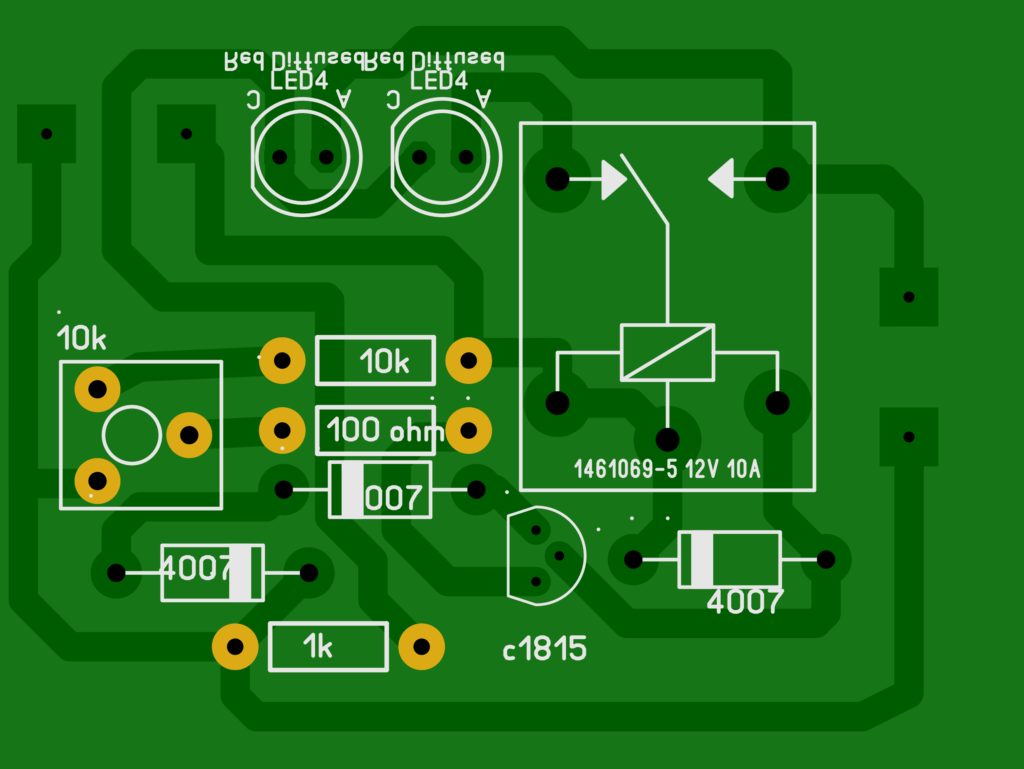

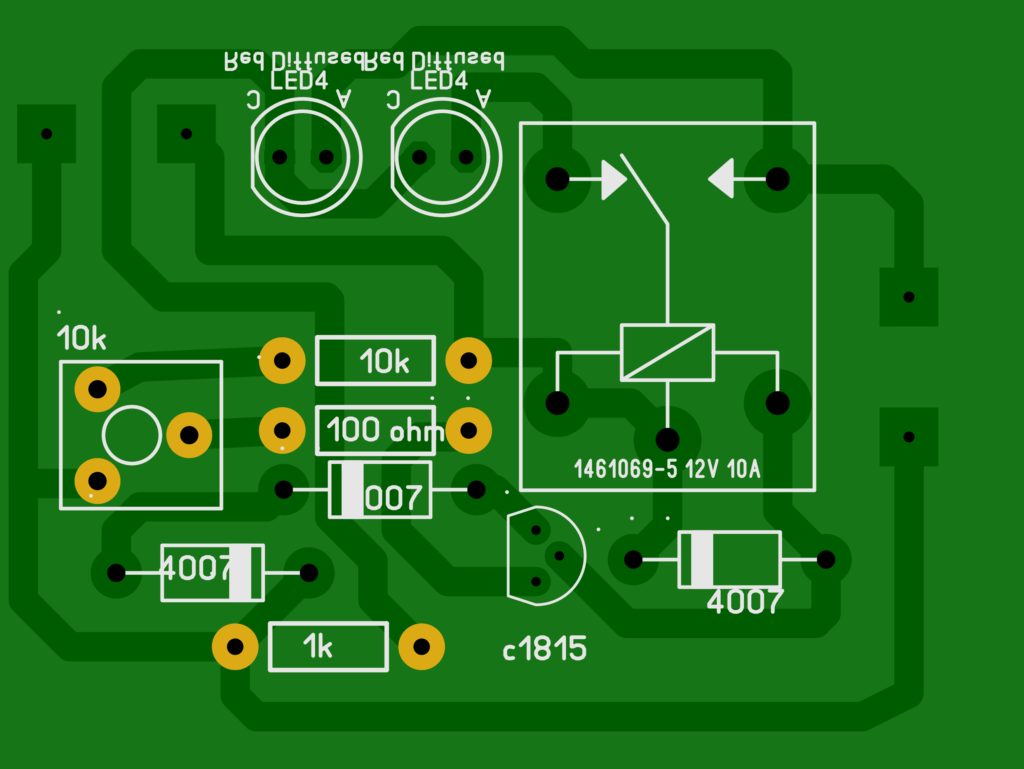

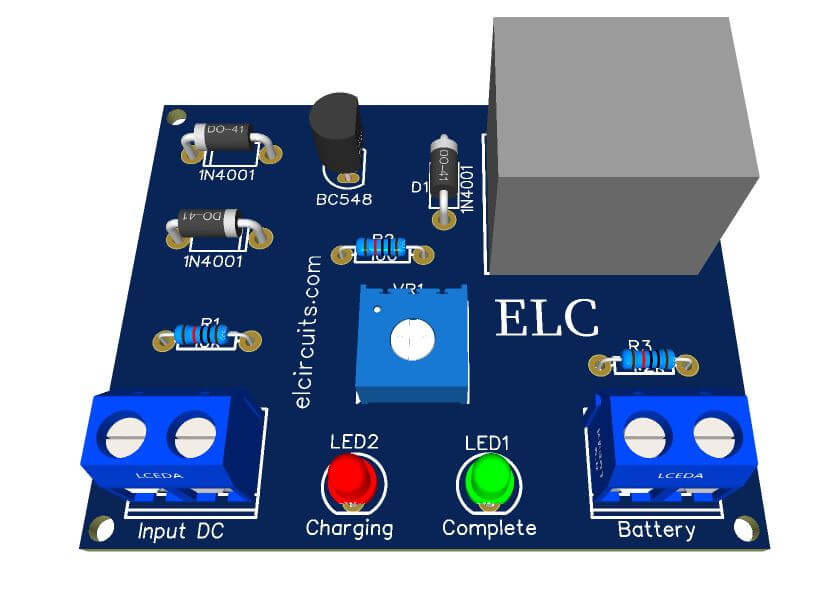

Simple 12V battery charger with automatic charging indicator + PCB Electronic Circuits

As the name states, there are three stages in this charger: bulk, absorption, and float. Let's discuss each stage. Bulk Stage About 80% of the battery is charged in the bulk stage. Here, a constant current of 25% of the Ah rating is provided. For example, in the case of 100Ah battery, 25A of constant current is fed and voltage increases with time. Battery Chargers are devices that recharge the batteries by putting energy into them. In this project, I will talk about one such battery charger module for charging Lithium Ion Batteries. It is TP4056 Li-Ion Battery Charger. Also read: HOW TO MAKE AN AUTOMATIC BATTERY CHARGER? A Brief Note on TP4056 Lithium Battery Charge Controller PMP8740 2-kW industrial AC/DC battery charger reference design with 92% full-load efficiency Overview A fully assembled board has been developed for testing and performance validation only, and is not available for sale. Design files & products Design files Download ready-to-use system files to speed your design process. TIDT140.PDF (3505 K) The TP4056 is a LiIon charger IC able to top up your cells at rate of up to 1 A. Many TP4056 boards have a protection circuit built in, which means that such a board can protect your LiIon cell.

12v, 7Ah Smart Battery Charger with PCB Diagram Engineering Projects

Basics of battery charging circuit design By Jeff Shepard | June 1, 2021 Charging batteries is simple (in theory) - put a voltage across the terminals and the battery charges. If safe charging, fast charging and/or maximum battery life are important, that's when things get complicated. Quick Steps to Make a DIY Battery Charger Circuit. So, here are the quick steps you should take to create a DIY battery charger circuit with power output and emergency power: 1: Build a bridge rectifier by connecting four 1N4007 diodes. 2: Solder the +Ve and -Ve terminals of the bridge rectifier to the secondary winding of the non-C.T transformer.

Charging time (for a given current) is ultimately determined by the battery's capacity. For example, a 3300 mAhr smartphone battery will take approximately twice as long to charge as a 1600 mAhr battery, when both are charged using a current of 500 mA. The Lithium-Ion Battery Charger Circuit is popular because of its excellent energy density, high cell voltage, and reasonable load characteristics. Everything from small electronic devices, smartphones, and laptops to vehicles now feature lithium chargers.

Anmbest 5S 18V 21V 15A 18650 Charger PCB BMS Protection Board, Liion Lithium Battery Charger

integrated circuit with a switching mode power supply (SMPS) to realize a battery charger. An example of realization of a 12V Nickel-Cadmium battery charger is given. 1 - TSM101 PRESENTATION The TSM101 integrated circuit incorporates a high stability series band gap voltage reference, two ORed operational amplifiers and a current source (Figure 1). In this section of the guide, we'll cover various battery charge circuit functions and configurations. We will go over the parts and principles for each. 12V Constant Voltage Battery Charger Parts List . To create your constant battery charge circuit for a 12V 100 Ah Battery, you'll need: 10kΩ Resistor x 2 (R1 and R2) 1KΩ Resistor (R3)