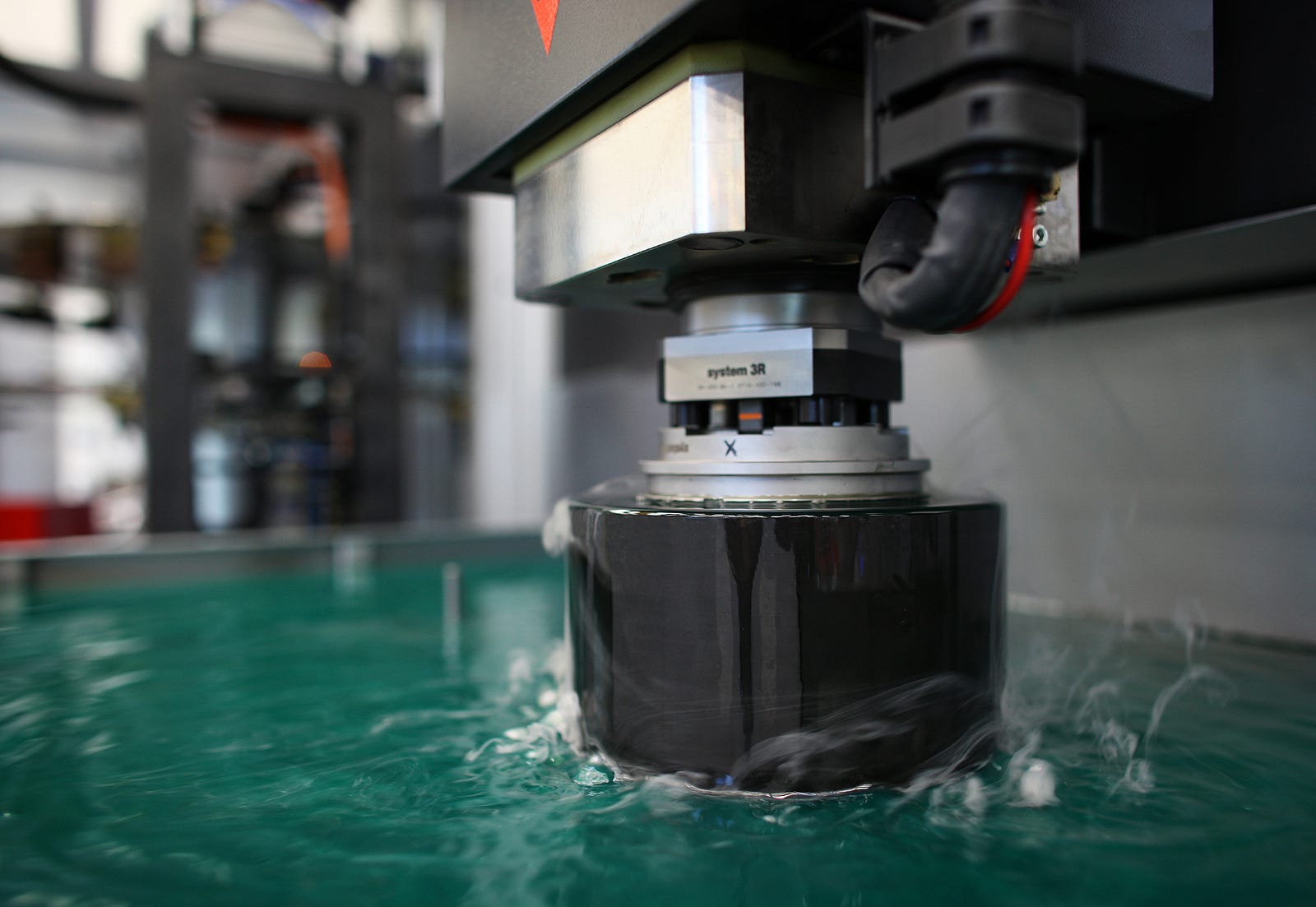

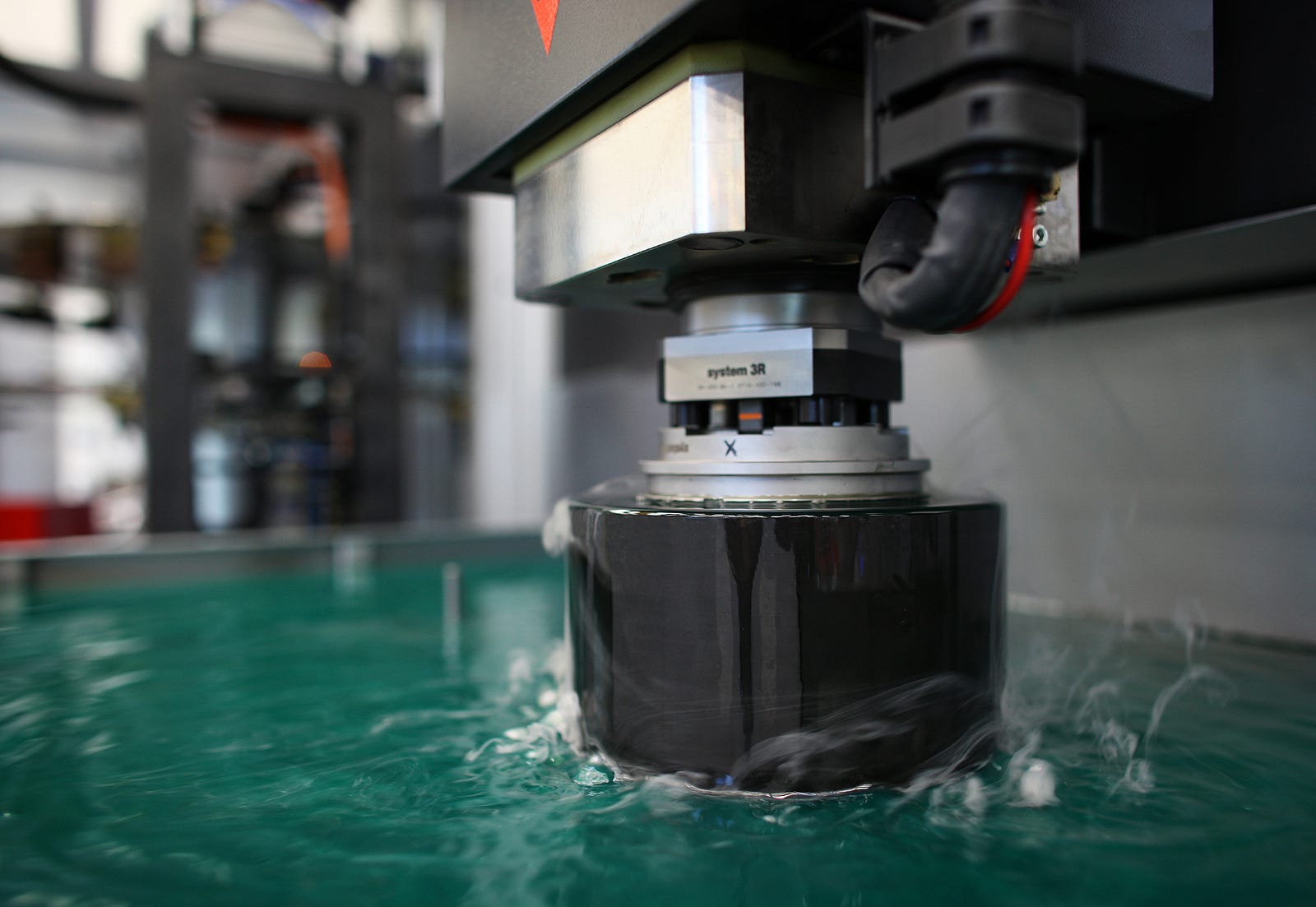

Step 1: What Is EDM Electrical discharge machining is a method of removing metal using an electric sparks, similar to a plasma cutter but on a much smaller scale and under water. April 30, 2021 Of all the methods of making big pieces of metal into smaller pieces of metal, perhaps none is more interesting than electrical discharge machining. EDM is also notoriously.

EDM (electric discharge Machining) Machine Walkthrough YouTube

DIY Wire EDM is finally a reality! This has been on our DIY CNC machine radar for quite some time, and finally we have done it. We added this attachment onto. EDM is the method of choice for hard-to-machine metals, high aspect ratio hole drilling, and precise surface finishes that let mating parts slip together with almost zero clearance. The trouble is,. Electrochemical machining, or ECM, is not to be confused with electrical discharge machining, or EDM. While similar, ECM is a much tamer process. Where EDM relies on a powerful electric. Homemade EDM (Electric Discharge Machining) Machine I made the majority of this homemade EDM a long time ago. Recently I have been finishing this project by making a better structure for the linear actuation, adding labels to the controls and other miscellaneous items.

EDM Electrical Discharge Machining 8 Steps (with Pictures) Instructables

My husband Ollie decided to build an Electric discharge machining (EDM) machine a couple of months ago. EDM machining is a process where a shape is obtained from a piece of metal by using sparks to remove material! Blog: https://blog.xuite.net/dcstudio/twblog/589518583 Welcome to the first episode of the Everything EDM - Learn to Burn series. Zero Tolerance LLC zeroes in on electrical discharge machining (EDM), starting fro. Electrical Discharge Machining (EDM) is a nonconventional machining process used primarily for tasks that would be unachievable with conventional methods. It uses electricity to erode the surface of conductive materials. Since no tool physically contacts the workpiece, EDM can maintain fine surface finishes even on intricate and delicate parts.

An Intro To Electrical Discharge Machining Keen Home Medium

Introduction to EDM Electrical discharge machining (EDM) is a fabrication technology that carves material off of a workpiece by producing many sparks between an electrode and the workpiece. Electrical discharge machining provides a way to cut metal without needing to develop high forces at the cutting tool. For this reason, EDM is a good candidate for machining metal using a RepRap-style machine.. DIY Electro Discharge Machine - 4 (uses a DVD player motor and diesel fuel)

T0VYrleH1-g|640|480

Current can be controlled electronically, but the voltage across the arc is mostly dependent on the gap distance between the electrode and workpiece, and has to be regulated mechanically (this coupling of the electronic and mechanical control is called the EDM servo system). The electrical properties of the spark gap also mean that the current E lectrical D ischarge M achining ( EDM) is a process that uses electrical discharges emitted from an electrode to erode an electrically conductive material. Therefore, it is possible to erode or "burn "electrically the reverse shape of the electrode into the work piece.

Wire Cut Electro Discharge Machining Process Working Animation Video Explained with Setup

Electical discharge machining is a techinque in which electricity is used to machine (cut, grind, etc.) metal. It usually invovles sophisticated tools and equipment, but not here! Watch this video for a guide to making a small electrical discharge machining machine with an old electric doorbell. EDM (Electrical discharge machining) machine built by myself at home. A new control strategy was applied to this system which does not rely on the traditiona.