The Ford Motor Company team decided to try to implement the moving assembly line in the automobile manufacturing process. After much trial and error, in 1913 Henry Ford and his employees successfully began using this innovation at our Highland Park assembly plant. What made this assembly line unique was the movement element. We aim to provide accurate and up-to-date information regarding Ford Motor Company production status. If you notice any inaccuracies, please let us know here. FoMoCo North America Production Status - Week Of August 8, 2022. Vehicle. Plant. Status. Restart Date. 2022MY Production Start Date. Ford E-Series.

PPT Ford Motor Company Supply Chain strategy PowerPoint Presentation ID337916

Fordism is an industrial engineering and manufacturing system that serves as the basis of modern social and labor-economic systems that support industrialized, standardized mass production and mass consumption.The concept is named after Henry Ford.It is used in social, economic, and management theory about production, working conditions, consumption, and related phenomena, especially regarding. DEARBORN, Mich., March 2, 2022 - Ford is continuing to transform its global automotive business, accelerating the development and scaling of breakthrough electric, connected vehicles, while leveraging its iconic nameplates to strengthen operating performance and take full advantage of engineering and industrial capabilities. "This isn't the first time Ford has reimagined the future and. After more experimentation, in 1913 the Ford Motor Company displayed to the world the complete assembly-line mass production of motor vehicles. The technique consisted of two basic elements: a conveyor system and the limitation of each worker to a single repetitive task. Despite its deceptive simplicity, the technique required elaborate. Standardization - Ford's production line did not provide for variation or deviation from the best practice. The employee who assembled the bumper for the car did so the same way, every day, once Ford determined the best way to do it.. However, the Toyota Production System (TPS) took Ford's process a step further. Ohno and other company.

Ford Motors Production Line, What It Looks Like 100 Years Ago And Now(Photos) Autos Nigeria

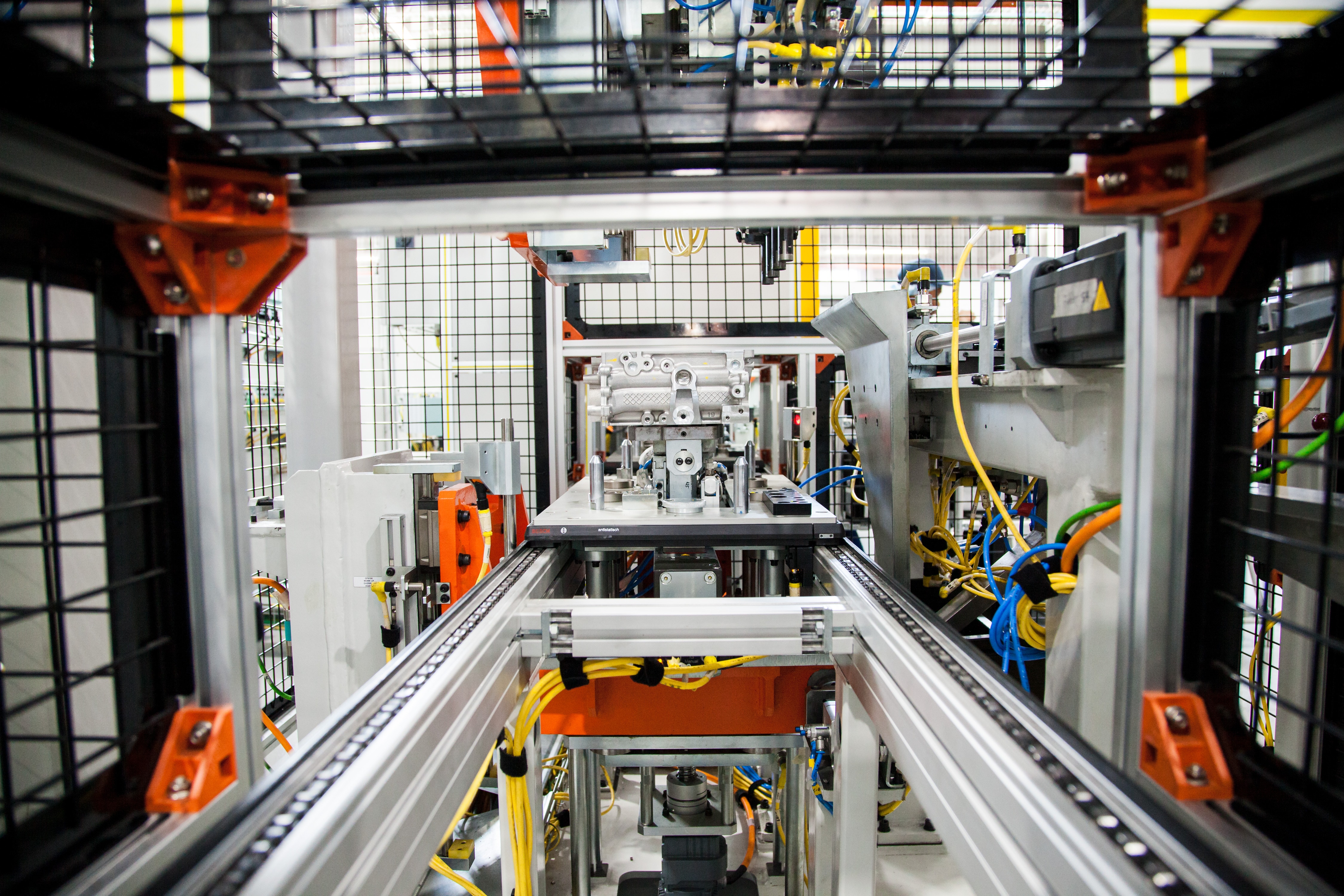

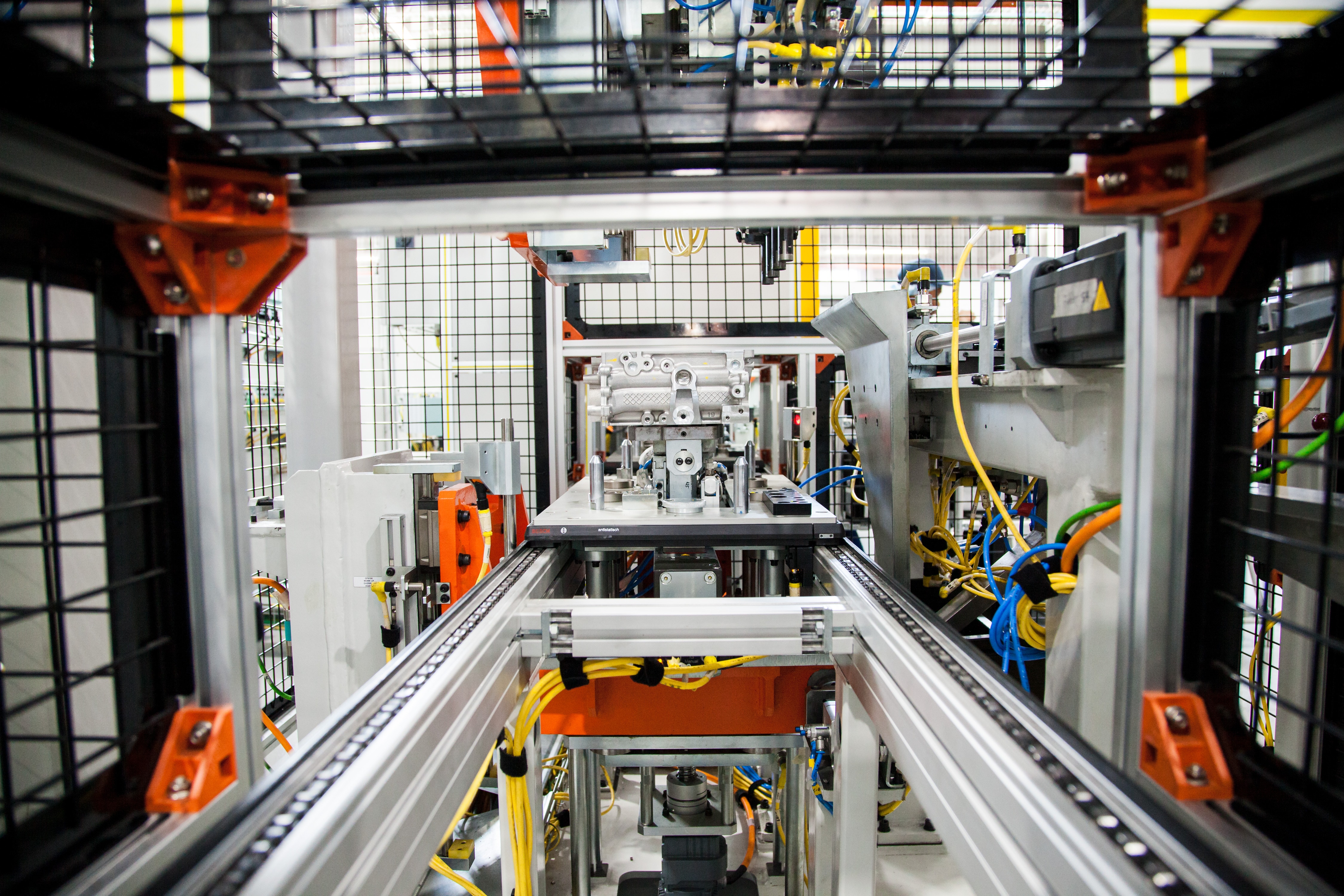

Augmented Reality. Augmented Reality has helped reduce the time it takes to make changes within the work and assembly areas of plants by 25 percent. In addition, this technology also helps to identify potentially dangerous processes to adjust them before the start of production and thus, protect both employees and production. Ford has pioneered several innovative automobile manufacturing techniques since its inception. In the mid 1990s, Ford restructured its manufacturing operations in its efforts to induce more flexibility and enhance the efficiency of its automobile production systems. The restructuring effort was known as Ford Production System (FPS). The case discusses the keys elements of FPS and how it was. For Ford, having the right technology in place was an enabler for production teams to move quickly and deliver with more precision or produce at lower cost, explains Johnson. "During our response to COVID-19, our use of technology helped our engineering team move more quickly to deliver much needed PPE to front line responders," he says. In the mid 1990s, however, this began to change with the introduction of the Ford Production System, in which all large manufacturing engineering programs in the Powertrain Group were centralized with an eye toward greater standardization. In 2000, Ford had adopted its Flexible Manufacturing System, a key component of which involved the.

Ford Motor Company constructeur automobiles crée le 16 juin 1903

On December 1, 1913, Henry Ford installs the first moving assembly line for the mass production of an entire automobile. His innovation reduced the time it took to build a car from more than 12. Ford/USPTO. A new patent registered to Ford Global Technologies on Tuesday could shed some light on the automaker's upcoming electric vehicle platform. The patent features a powertrain setup.

Fordism, a specific stage of economic development in the 20th century. Fordism is a term widely used to describe (1) the system of mass production that was pioneered in the early 20th century by the Ford Motor Company or (2) the typical postwar mode of economic growth and its associated political and social order in advanced capitalism. Ford patent shows new Ultium-like EV platform. The patent, filed with the USPTO, was published on January 2, 2024,. It's for a "Vehicle Chassis with Interchangeable Performance Packages and.

Ford Struandale Engine Plant Using the World’s Best Practices to Optimise Exportdriven

Ford has pioneered several innovative automobile manufacturing techniques since its inception. In the mid 1990s, Ford restructured its manufacturing operations in its efforts to induce more flexibility and enhance the efficiency of its automobile production systems. The restructuring effort was known as Ford Production System (FPS). The case discusses the keys elements of FPS and how it was. In January 1995, Ford initiated Ford 2000 program, which was aim to develop and implement a new manufacturing system called the Ford Production System (FPS). According to Ford's website, "The vision of FPS is a lean, flexible and disciplined common production system, defined by a set of principles and processes, that employs groups of capable.