It has been produced artificially and is also known as "green gold". [3] Electrum was used as early as the third millennium BC in Old Kingdom of Egypt, sometimes as an exterior coating to the pyramidions atop ancient Egyptian pyramids and obelisks. It was also used in the making of ancient drinking vessels. Whether nickel aluminum bronze, manganese bronze, or anything in between, green alloys are environmentally-friendly metal alloys that have an extremely low lead content, or no lead at all in some instances.

Green Alloy Wheels find the perfect alloys and buy online LK Performance

The man-made alloy of gold and silver is chemically similar to electrum but usually is called green gold . Electrum Chemical Composition Electrum consists of gold and silver, often with small amounts of copper, platinum, or other metals. Copper, iron, bismuth, and palladium commonly occur in natural electrum. Greenhouse Gas Emissions Associated with Primary Metal Production shows that the various forms of greenhouse gases can be divided into two groups, both of which are important when addressing metallurgical process emissions and mitigation strategies. Green metals. Green metals is a term used to describe a set of metals that are utilized in clean energy applications and can help achieve net zero emissions targets. [1] [2] These metals include copper, nickel, zinc, cobalt, neodymium, graphite, lithium, manganese, and molybdenum. [2] [3] The measure of "green" (Clc) includes carbon (Cm) related to the mining of raw materials, carbon (Ct) from transporting the metals, carbon (Cp) from refining and purifying the metals for use, carbon (Cf) from melting and forming the metal, carbon (Cr) from the recovery and recycling of the metal so it can be used again, and last, the carbon (Cd).

Green Metals in Focus Vanadium Capital 10X

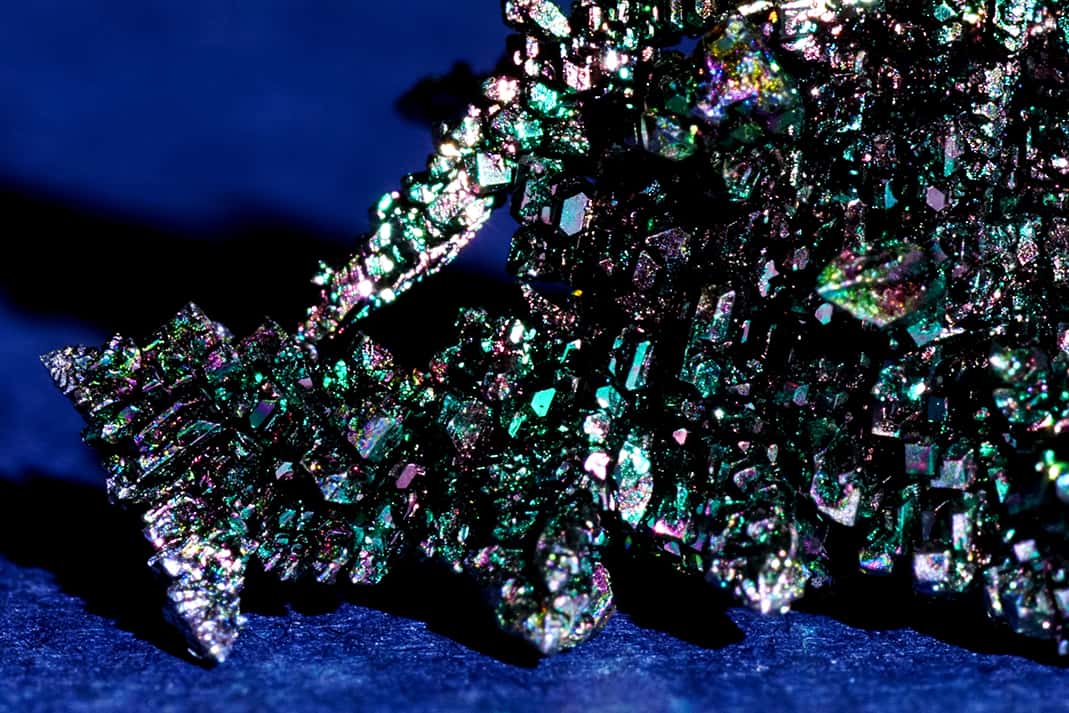

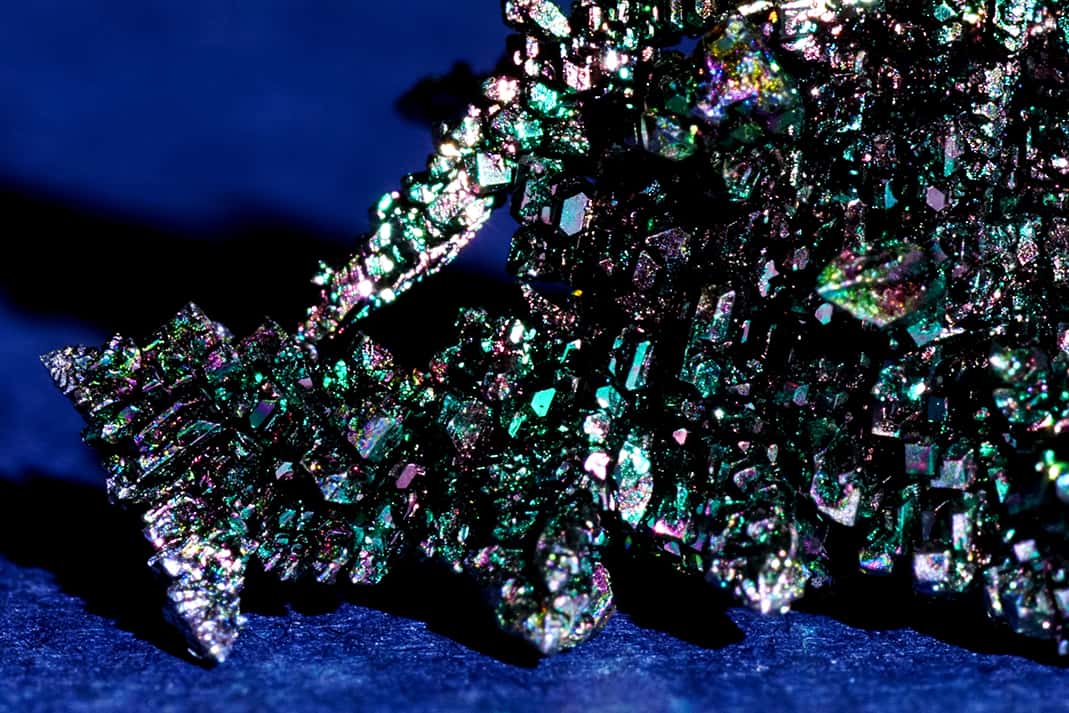

Researchers use rare-earth metals in alloy powders to produce green, eye-catching sparklers by American Chemical Society Graphical abstract. Credit: ACS Omega (2022). DOI:. Sustainable Metallurgy and Sustainable Metals. Metallic materials such as steels, aluminium, titanium, lithium or nickel which have enabled progress over thousands of years and given entire ages their name, are now facing severe limits set by sustainability . The accelerated demand for practically all structural alloys in key areas such as. Composite development gravitated towards the use of efficient materials, which include metal-based alloys, polymeric composites, and metal-organic frameworks (MOF) [84]. Green metal-based. Green Quicktake How Steel Could Become Green, and What It Would Take A worker supervises the flow of hot liquid metal as it flows from the blast furnace at the Evraz Consolidated.

Polished brushed green metal texture 09849

What Is Green Aluminum and Why the Shift? The global aluminum market is in considerable expansion, expected to reach a value of $86.5 billion by 2025. The growth is attributed to ongoing demand increases in several key markets, including in the auto, beverage, construction, and electrical market. - SMS group GmbH British Indian Ocean Territory What are green metals? Why are metals so essential for our lives and for the world? Why do they have to be made "green" and how can this be done? We want to provide all the answers to this in a multi-part series.

Alloys with silver and copper in various proportions, producing white, yellow, green and red golds. These are typically malleable alloys. Intermetallic compounds, producing blue and purple golds, as well as other colors. These are typically brittle, but can be used as gems and inlays. Surface treatments, such as oxide layers. Audubon Metals to commercialize Ohio State green aluminum alloy technology. The Ohio State University and Audubon Metals have entered into a licensing agreement to advance commercialization of technology that could increase manufacturing usage of recycled aluminum alloys, which cost half as much and require a fraction of the energy of mined alloys.

Concast Metal Products Green Alloys YouTube

A promising new metal alloy system could lead to commercially viable magnetic refrigerants and environmentally friendly cooling technologies, according to a scientist at Rochester Institute of. Energy saving has become a priority for welding industry. This is due to the recent increase in energy demand and constraints in carbon emissions. Increasing environmental demands from governmental and customers strain the importance of reducing the environmental pollution while welding. Therefore, the minimum energy-oriented green welding process is must. Friction stir welding (FSW) is.