Homemade Sheet Metal Bender Creative Mind 54K subscribers Subscribe Subscribed 30K Share 3.2M views 4 years ago Homemade Sheet Metal Bender I have used 2.5 feet long 50/50, 4 mm thick angle. DIY Sheet Metal Bender - Diy Projects Iron Man Restoration 184K subscribers Subscribe Subscribed 60K Share 6.1M views 3 years ago #diyprojects #homemadetools #diy In this video i have made.

Plans for a DIY Sheet Metal Bender Etsy UK

Step 1: Tools and Materials Tools 1. Angle grinder 115mm 4 ½" or 125mm 5" Angle grinder 180mm 7" 2. Cutting disk according to grinder ø115 x 1mm/ø4 ½" x 0.04" or ø125 x 1mm/ ø 5" x 0.04" Grinding disk 180mm 3. Drill Need to bend sheet metal? It's really easy to build a simple DIY metal brake!!TOOLS & SUPPLIES:https://kit.co/iliketomakestuff/my-metalworking-toolshttps://k. Step 1: What I Used I used the following items for this build: (1) 1/8" x 1.5" x 1.5" x 4' Steel Angle (1) 1/8" x 2" x 3' Steel Plate (1) 1/2" x 3' Steel Box (1) 3/4" x 2.5" x 6' Dimensioned Board (2) Hinges (6) 1" x 5/16" Cap Screws (6) 5/16" Lock Nuts (10) 1" Drywall Screws (2) 5/16" Wing Nuts (2) 5/16" Washers (2) 5/16" x 2.5" Carriage Bolts The Family Handyman. Bending sheet metal and flashing into crisp angles is easy with this two-board bending tool designed by reader Wayne Jung. To build one, you need just a couple of short boards, a few screws and access to a table saw. Set the table saw fence far enough away from the blade to slice off a 1/16-in. wide x 2-in. deep notch, then push one board edgewise through the saw to create.

Plans for a DIY Sheet Metal Bender Etsy

How To Bend Sheet Metal With Common Tools If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal without needing a brake. On our farm, we've got an old outbuilding and a dream to build a party barn. Progress is coming along nicely. 1 Select materials that will be strong enough for your needs. 1⁄4 inch (0.6 cm) steel plate with bracing will enable you to bend 14 gauge galvanized steel sheet metal in lengths up to about 3 feet (0.9 m), which is the size and specification for the project described in this article. Here are some materials used to build this particular brake. STEP 3: ATTACHING THE FLAT METAL PIECES. TIP: Place scrap 2×4's under the boards to raise the brake so clamps can secure the metal to the brake. You are now going to attach the two 12.5″ flat metal pieces to the boards. These will be placed between the hinges with a gap of 1/4″ from both hinges. Metal brakes are machines used to bend sheet metal into any desired shape to be used for building projects, and other constructions. A metal brake is quite affordable, but it's always a thing of joy to build one yourself with a few cheap and available materials and tools.

DIY Sheet Metal Bender Diy Projects YouTube

Plans: https://www.etsy.com/de/listing/998022110/plans-for-a-diy-sheet-metal-bender?ref=shop_home_active_1Plans to my other projects https://madebythemetalis. 1 Gather your materials. Having the right tools on hand will help this process go smoothly and quickly. To bend your sheet metal with a vise and hammer, you will need: 2 wooden or metal form blocks Block of hardwood and heavy-duty hammer or mallet (optional) Calculator or online bend calculator Marker Protractor Rubber, plastic, or rawhide mallet

Bending sheet metal with a vise is a slow and laborious process. This simple homemade brake will cut your bending time in half. The DIY Sheet Metal Brake is an inexpensive angle iron and hinge construction that makes bending sheet metals, copper, copper alloys, and other similar materials a lot easier. Easy to build, no welding required! DIY Sheet Metal Bender Brake Fully Modified : 5 Steps - Instructables DIY Sheet Metal Bender Brake Fully Modified By kess_gr in Workshop Metalworking 20,886 65 5 Download By kess_gr Follow More by the author: At a previous instructable, we had seen the build of a simple version, Sheet Metal Brake.

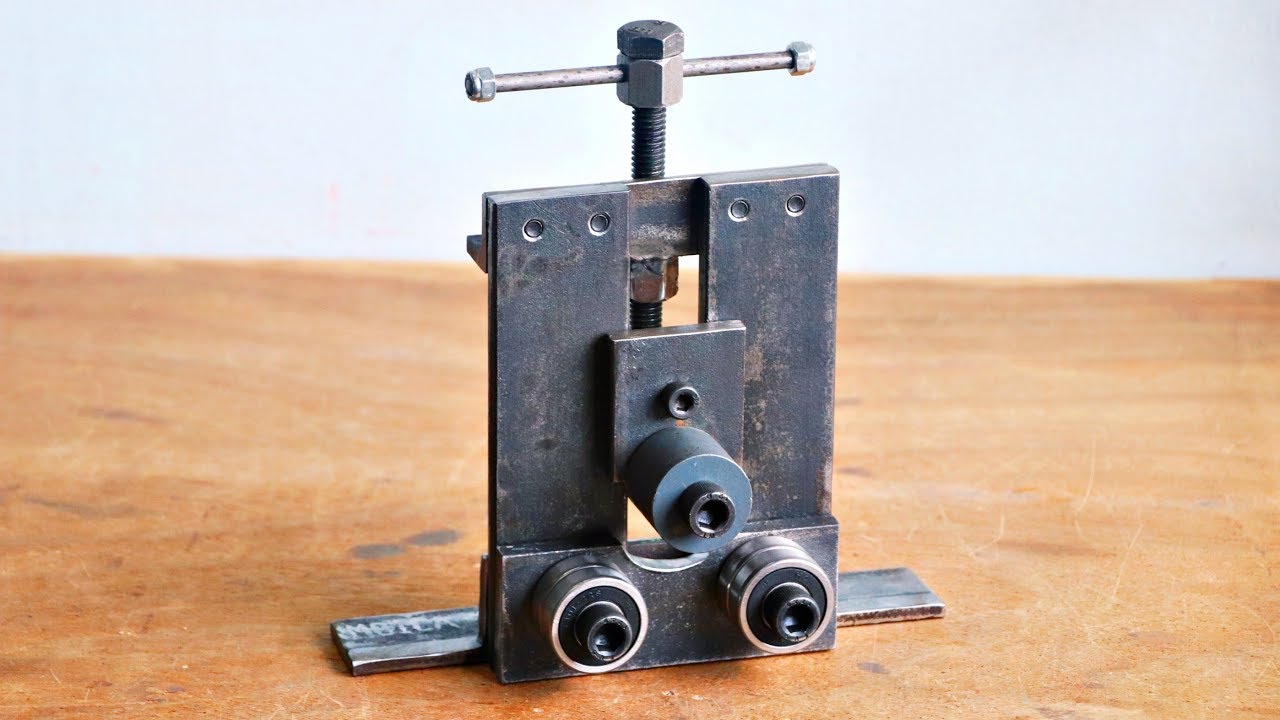

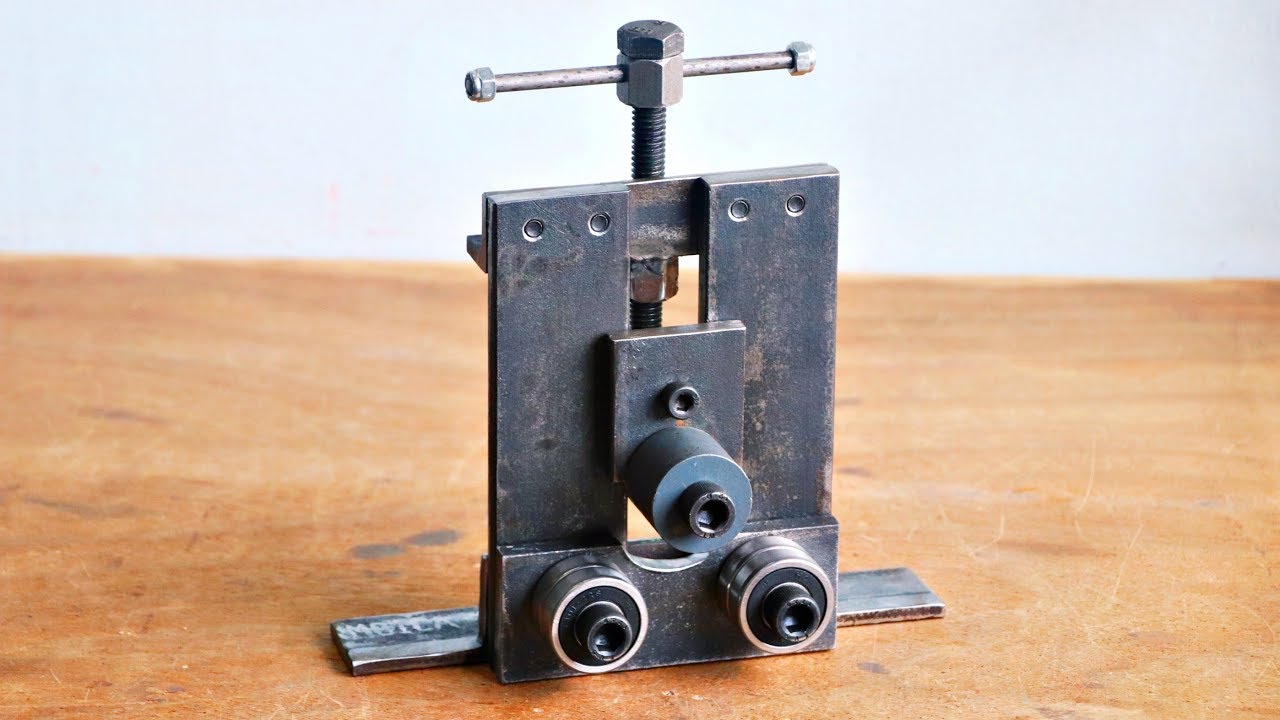

Make A Metal Bender Homemade Roller Bender YouTube

How to make : Step 1 :- Cut The L- section channel First step of making a sheet metal bending tool is cut the two L- section channel of correct size. Step 2 :- Attach hinges After cutting of L - section channel next step is attach this two channel by hinges as shown in the image. first create holes for screws to atach the hinges. This homemade metal bender is very simple and easy to make. High thickness metals can also be eas. Hello Everyone!Today I show you how to make a metal bender.