With over 100 years of application expertise from the Henkel adhesive business, LOCTITE 3D Printing is leveraging deep application knowledge to develop high-performance photopolymer materials, transforming unique needs into scalable manufacturing processes. Are you exploring different photopolymer materials? Have a unique material need? The Promise Realized. LOCTITE's new 3D portfolio of resins, post-processing bonders and equipment, and printers addresses those shortcomings. It expands the available materials for 3D printing - and the properties they possess. It allows you to create truly functional parts, across a wider u0003range of applications.

LOCTITE 3D Printing EQ DW11 3DP4U

LOCTITE® 3D Printing provides high performance resins designed to operate in a broad range of DLP/SLA platforms for large scale production. Loctite 3D PRO9274 is a durable dark gray resin that enables fast printing of highly detailed parts. Designed to seamlessly print on various types of DLP/LCD printers the material enables users to produce a broad range of products all at a cost-effective price point. LOCTITE 3D Printing provides a wide range of high-performance engineering-grade resins specifically designed for industrial applications. Designed for various DLP and LCD platforms, LOCTITE resins have the mechanical properties to support aerospace, automotive & transportation, industrial & manufacturing, medical, and consumer goods applications. LOCTITE 3D materials are available globally, and with Henkel's legacy of business excellence, customers have the security of working with one of the world's largest industrial materials companies that is committed to bringing LOCTITE Additive Manufacturing solutions to industry.

Henkel Onboards Prodways As Its New Loctite 3D Printing Ecosystem Partner Manufactur3D

Henkel launches a new class of 3D Printing resins for healthcare applications under its leading Loctite brand. The broad portfolio of high-performance photopolymers offers a range of biocompatibility standards from safe to touch parts to medical devices. In addition to the established portfolio of Loctite 3D Printing resins, the company innovates to deliver tailored formulations to fit the. Welcome to Learn with LOCTITE 3D Printing! This video series will teach tips and tricks to make the most of your Loctite 3D printing materials. In this episo. LOCTITE® 3D Printing PU Bonder is a 2-component polyurethane adhesive specifically designed for bonding multiple substrates with rapid fixture and gap filling properties. This product is suitable as a surface filler during the repair of 3D printed models. Excess adhesive on the part can be easily sanded for good surface finish. For easy application, use the manual gun (50 ml dual cartridge. LOCTITE brings new substance to the promise of 3D printing with their new, industrial-grade 3D printer and a complete range of differential manufacturing resins. Designed for truly functional prototyping and speedy, multi-component production, LOCTITE's portfolio of resins and equipment turns your 3D vision into reality.

LOCTITE 3D 3818 High Accuracy

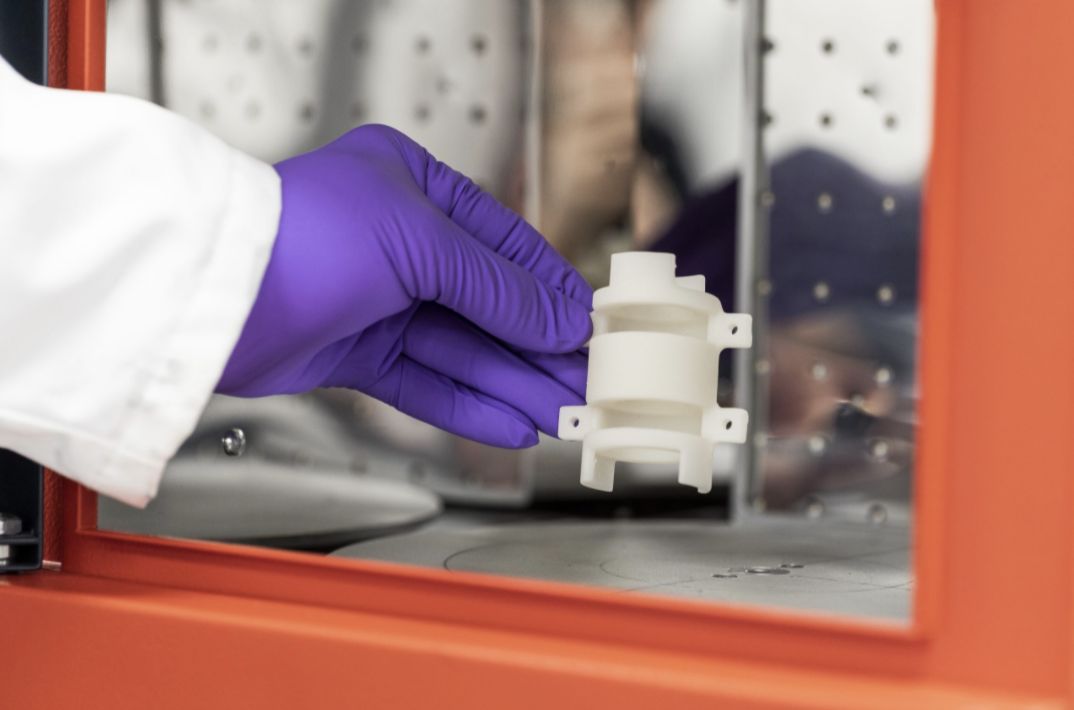

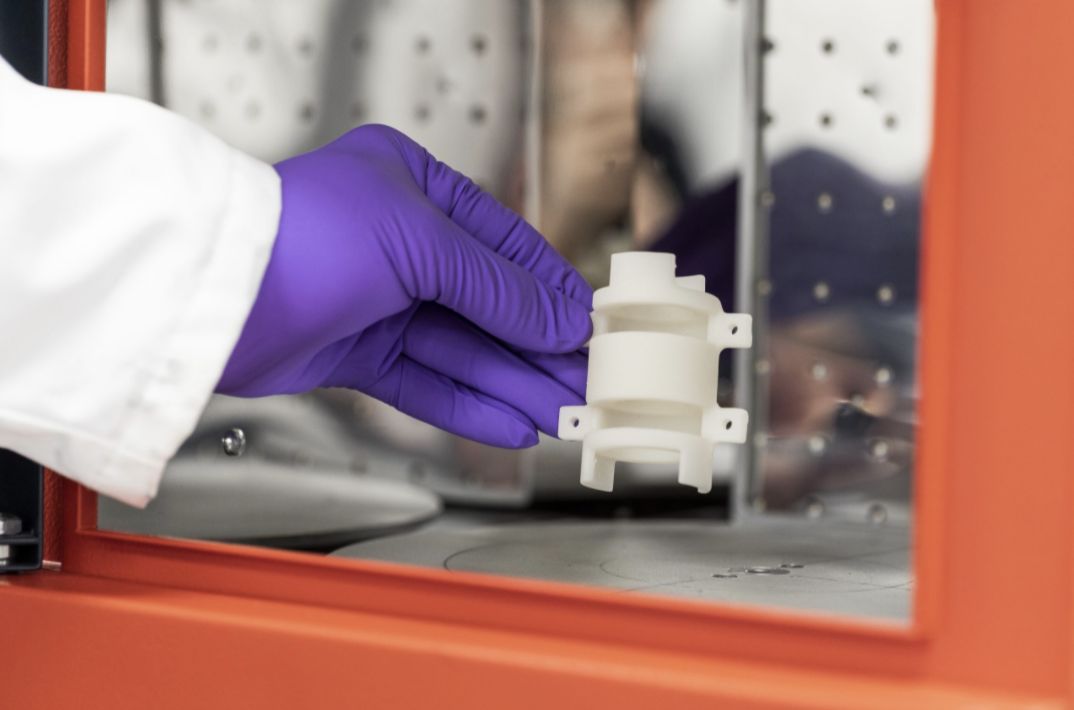

The high degree of design complexity, offered with 3D printing, is appealing, but the practical limitations of slow print speed, build space and the need for post-processing of printed. space of the printer .LOCTITE 3D Printing Universal Bonder was used to assemble the final parts, because it offers a good performance on PA12 . Additionally. The LOCTITE® CL36 LED Curing Chamber a high-performance LED system for curing UV resins. The chamber is a closed system permitting manual loading of the cure chamber. 405 nm UV light from multi-directional UV LEDs and a rotating turntable ensure uniform dosing and complete penetration, to achieve the most desirable finish for all engineering resins.

Now certified for Carbon 3D printers, Loctite 3D IND405 Clear is a tough, semirigid material produced as a one-part resin, making the clear polymer easily printable through Carbon's DLS process. 3D PRINTING MATERIAL SOLUTIONS FOR HEALTHCARE Loctite Additive Manufacturing LOCTITE 3D Printing Resins for Healthcare Applications MEDICAL WORKFLOW VALIDATIONS Product Code Version Printer Model Build Style Operation Conditions Model Clearing Fluid Process Operating Conditions Duration Model Process Operating Conditions Duration

iMakr Loctite 3D Printing LED Cure Chamber Loctite Accessories

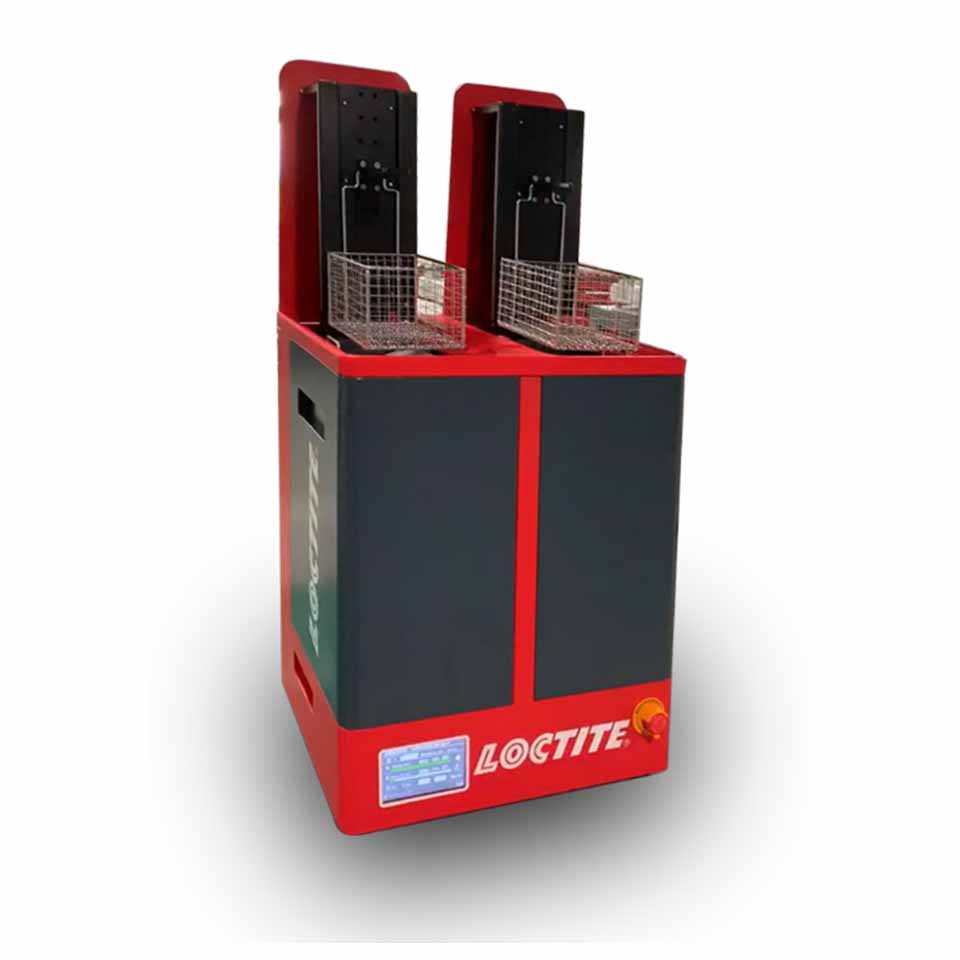

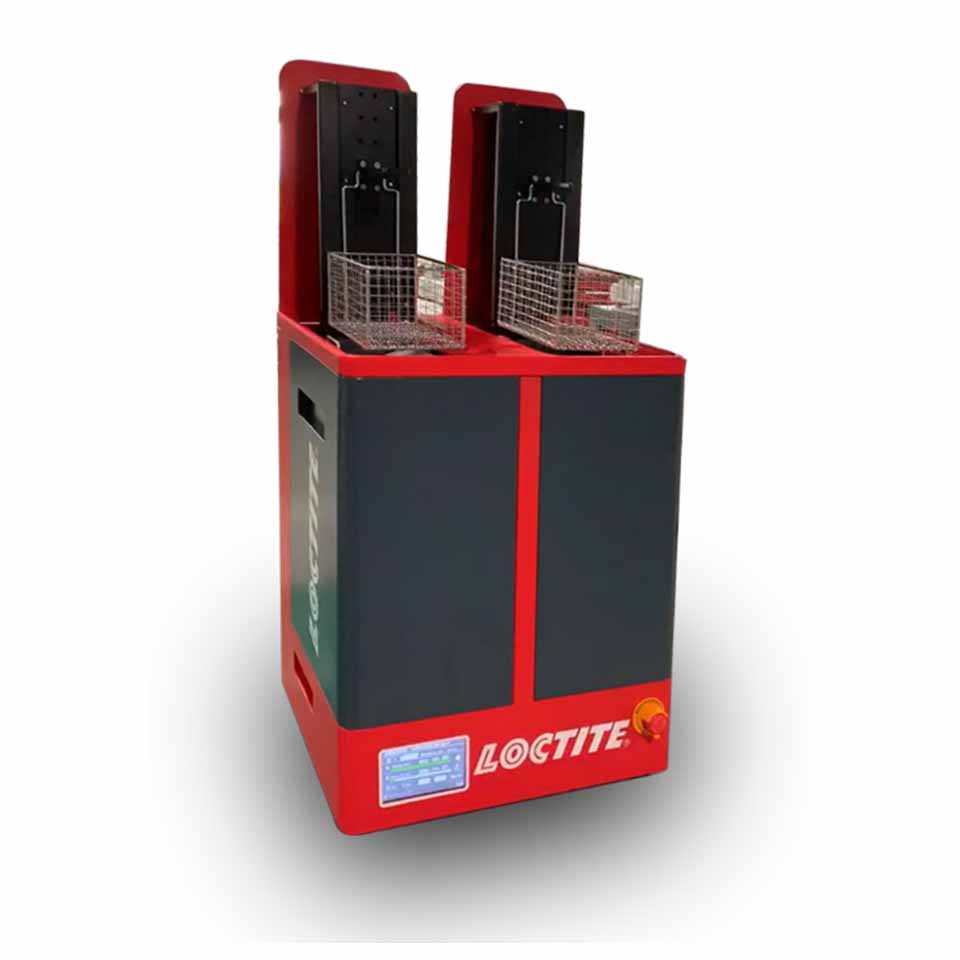

The Loctite 3D Printing portfolio from Henkel offers a vetted ecosystem of partners and revolutionary performing materials that enable the use of additive manufacturing for a wide range of applications with validated workflows. With this joint alliance, the companies bring together the combined expertise of fast printing using high resolution. To maintain equipment, removable tanks enable cleaning at the end of each shift. The washer is designed to work with Loctite 3D Printing Cleaner C to ensure the best performance.".