by Jackson O'Connell Updated Jun 11, 2023 PETG is a durable, non-toxic filament that can be difficult to print. Learn how to find the best Cura PETG settings/profile for your needs! Fine Tuning Print changing only layer height slightly and check the results until you find the perfect layer height for your specific project. Ideal PETG Layer Height: For Detail: 25% of nozzle size or extrusion width (0.1 mm for 0.4 mm nozzle) Overall best layer height: 25% - 40% of nozzle size or extrusion width (0.15 mm for 0.4 mm nozzle)

PETG Cura Settings

Find the best PETG print settings for your needs, by adjusting things like temperature, stringing, print speed, and retraction settings! June 25, 2023 3DSourced Guides, 3D Printer Materials, Feature Stories, Filament, Rigid Ink Is PLA or ABS not cutting it anymore? For something more durable that can handle higher temperatures than PLA, but is easier to print than ABS - PETG is the filament for you! 0:00 / 7:45 How to 3D Print PETG Filament! Tips and Settings to 3D Print PETG Like a Pro - Cura tr3nD maker 5.29K subscribers Subscribe Subscribed 3.6K 118K views 2 years ago #3dprinter #petg. Printing Temperature As the materials that a filament is composed of affect the filament's melting point, you'll notice that the recommended print temperature values (usually listed in the specifications section of the product page) show slight differences across various brands of PETG.

The Best Cura PETG Settings / Profile All3DP

Setting the proper retraction is essential. Without the appropriate retraction settings, you will face issues like stringing. This keeps the filament from oozing out too much from the nozzle. There are two settings that you have to go through for retraction. It's the retraction distance and speed. Navigate to the Prepare tab on the top of the Cura window. Click the middle pane below (with material and nozzle size information). Click the material dropdown, and choose Manage Materials. Click Generic PETG from the list on the left, and hit the Duplicate button. Sponsored by https://www.creality3dofficial.com by Comgrow.Chuck gives you some Tips for printing with PETG along with sharing his PETG Cura Profiles on this. How it was Done. In this video I explore some of the PETG print settings for Cura including printing on a Bowden and Direct Drive, speed, retraction, support, and much more. PETG (Affiliate link, no extra charge to you) eSUN Opaque Black PETG: https://amzn.to/2IZIfQ2. eSUN Semi-Transparent Blue PETG: https://amzn.to/2s1JqUC.

Cura profile for PETG? Filament Lulzbot

Set up your print bed If you've ever printed with ABS, then you know how complicated it is to get the first layer of the ABS print to stick to the print bed. PETG is also somewhat problematic, but in the opposite manner - it sticks a little too well. Get retraction perfect. I'm using the same retraction settings for PETG as PLA. Don't attempt PETG if you can't get a perfect print with PLA. You may have other issues at hand. Start with a fresh spool to take out some of the moisture variables. Start on the low end temperature of your recommended filament setting and a bed heat of 70*C.

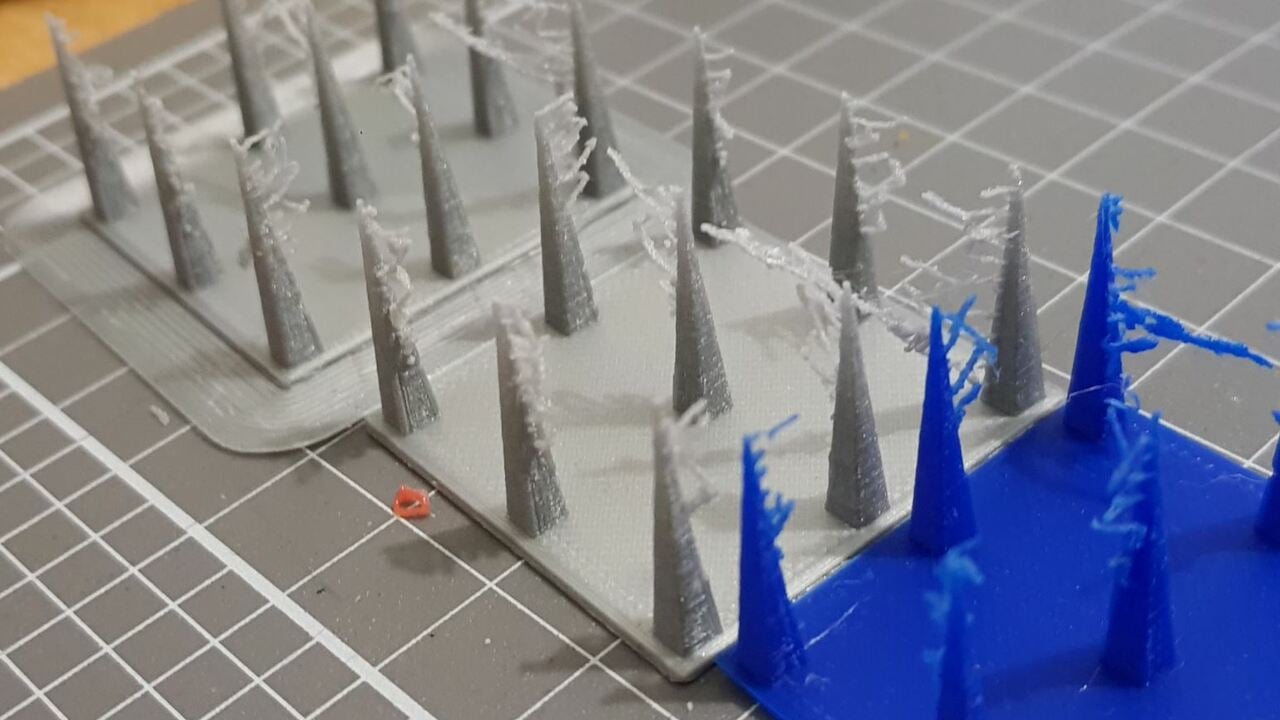

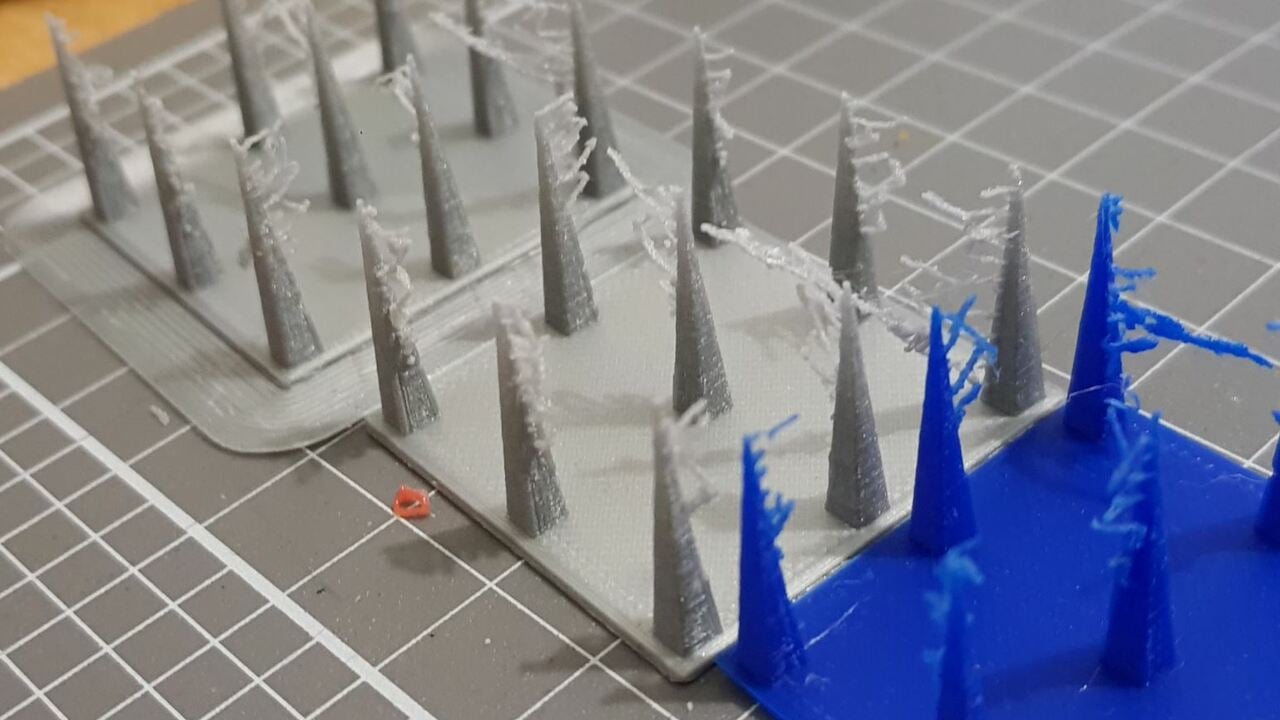

PETG Settings. These are the correct Cura settings for the Creality K1 for PETG: Print temperature: 250-270 °C; Print bed temperature: 70-75 °C;. 0% cooling, 100% extrusion width, 100% layer height; PETG filament is renowned for its strength and flexibility, but it tends to string, which can be quite problematic in 3D printing. Stringing. The best settings for retraction for the QIDI Tech X-Max 3 in Cura: PLA: 1,0 mm at 30 mm/s. ABS: 1,0-1,2 mm at 30 mm/s. TPU: 0,8-1 mm at 30 mm/s. PETG: 1,0 mm at 30-40 mm/s. Incorrect retraction settings in 3D printing can lead to a range of issues that detrimentally affect the final print quality.

Ideal Cura PETG Settings & Profiles for Perfect Prints! 3D Solved

PETG, or Polyethylene Terephthalate Glycol, is a type of filament widely used in 3D printing. It's a variant of the standard PET (Polyethylene Terephthalate) material, with the 'G' standing for 'Glycol'. Glycol is added to the material composition to prevent crystallization and increase the material's durability. The material used for 3D printing is called filament, which is heated by the extruder and extruded through the nozzle. The molten filament is deposited on the print bed to build a 3D model layer by layer. Filaments are made of a variety of materials, and different materials have different properties. The most commonly used are PLA and ABS filaments, which are simple and easy to use. But in.