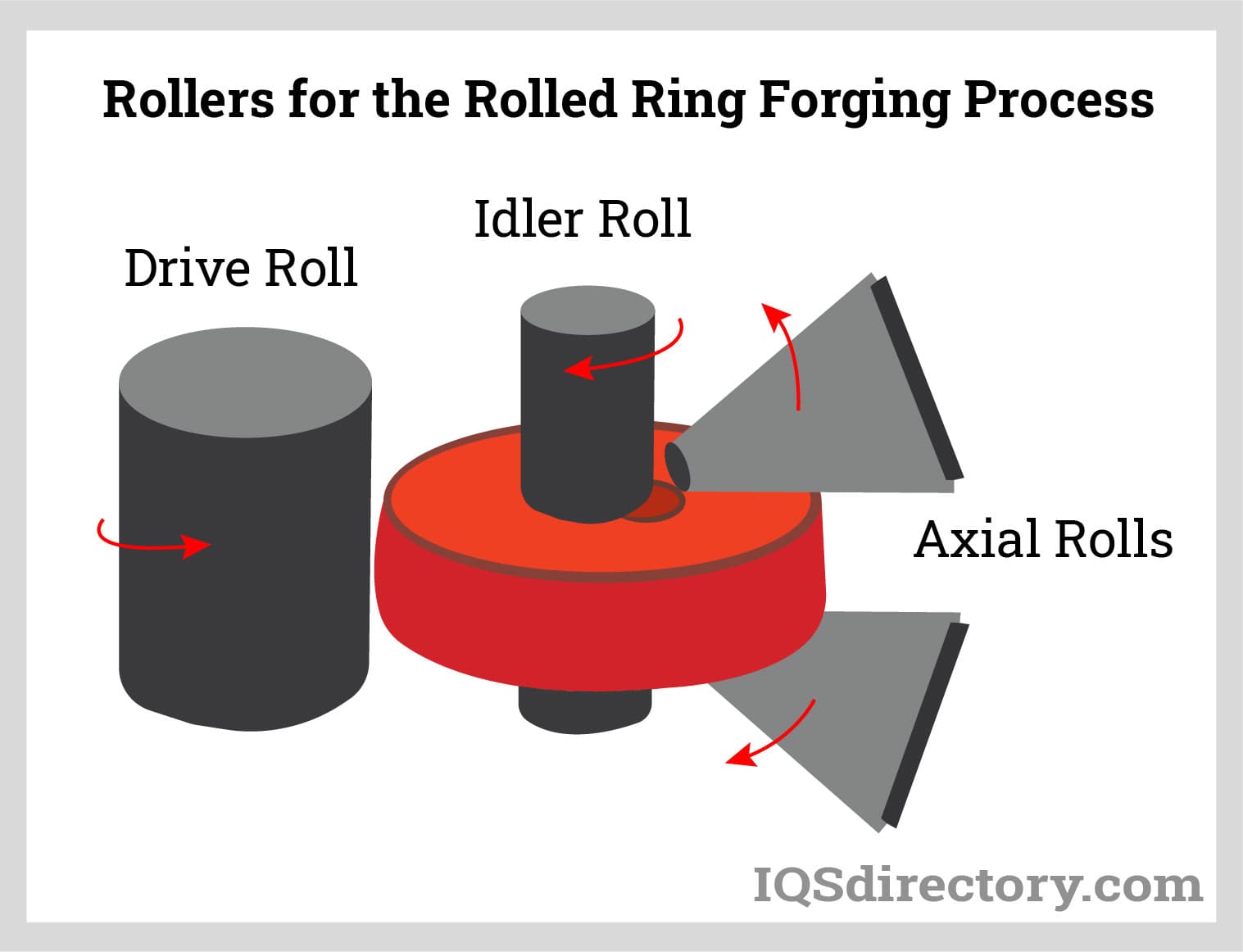

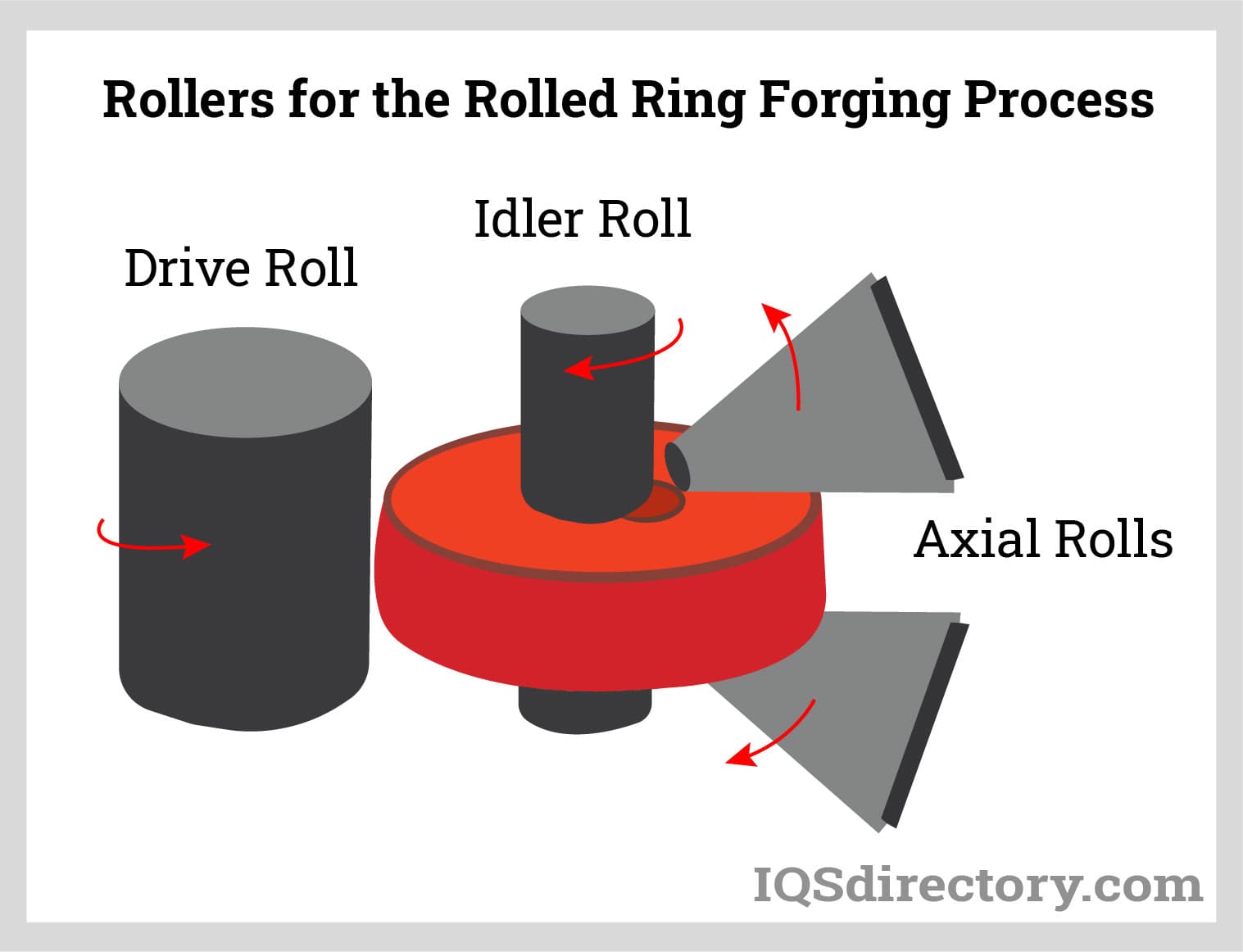

1. Starting stock first rounded, then upset Starting stock cut to size by weight is first rounded, then upset to achieve structural integrity and directional grain flow. 2. Workpiece is punched, then pierced 3. Ready for placement on ring mill for rolling Rolled ring forging process: 4. Ring rolling process begins with the idler roll Rolled rings are forged from many materials including stainless steel, carbon steel, alloy steel, aluminum alloy, brass alloy, titanium alloy, nickel alloys, copper, and many others. These forgings can meet nearly any strength requirement, whether for stress, impact, or load. Visit the forged materials section to see a full listing.

Rolled Ring What Is It? How Does It Work? Seamless

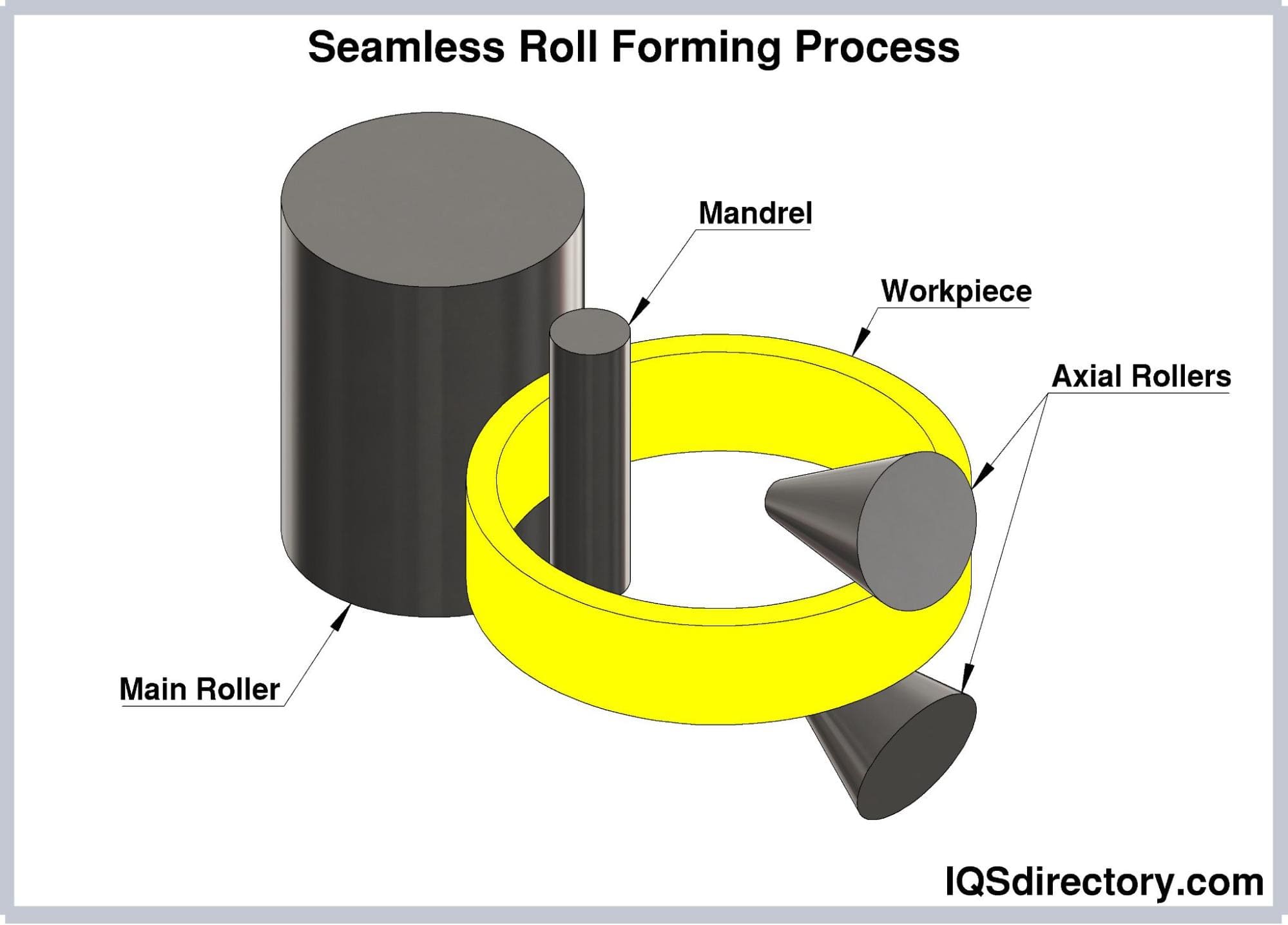

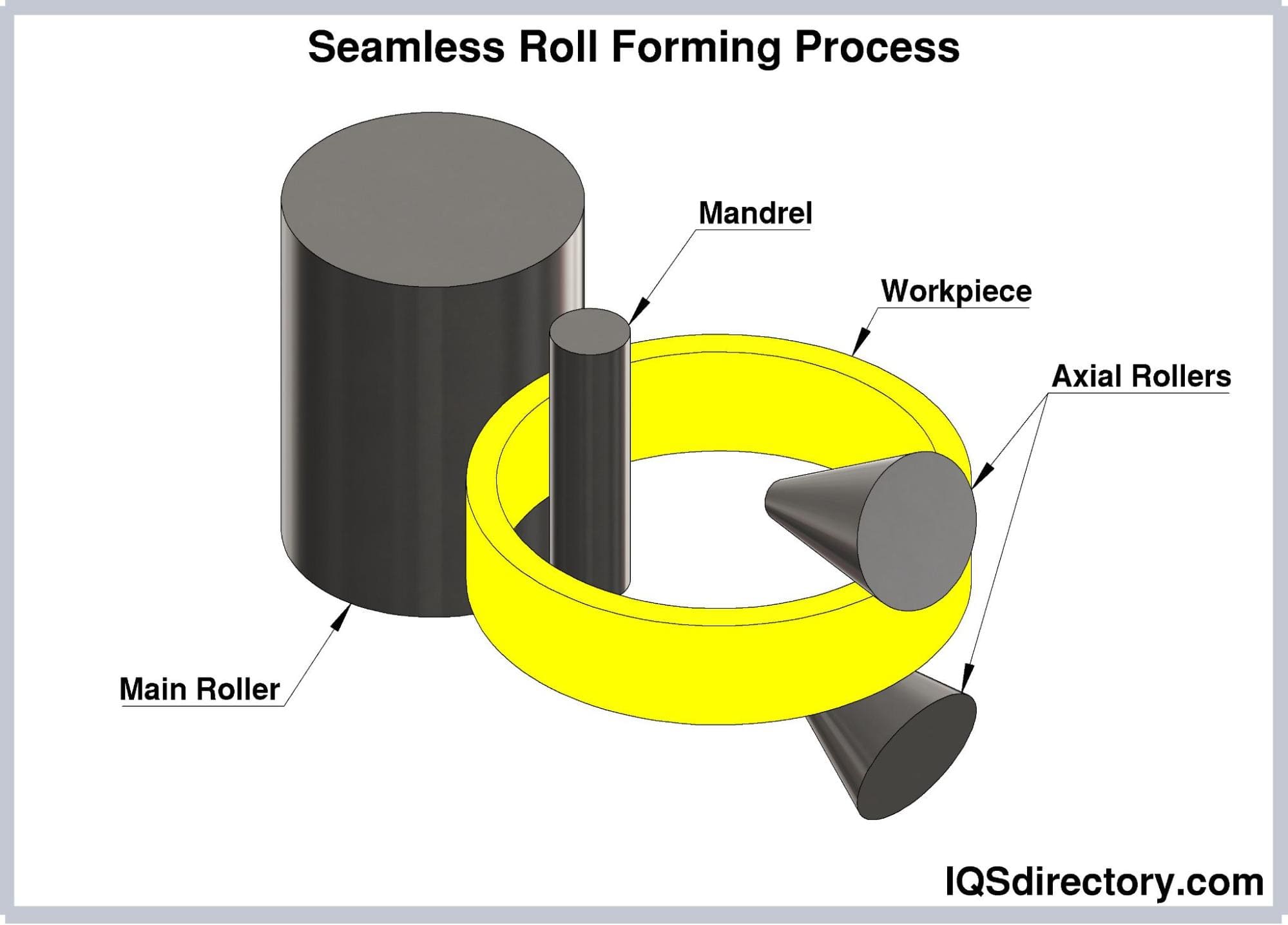

Our seamless rolled rings can be forged into various configurations to suit your needs. Ranging from flat, rectangular-cross section parts to tall, cylindrical shapes, every ring delivers high strength and toughness. Rolled ring forging is a metalworking process that begins with a circular preformed piece of metal that has been upset and pierced to form a doughnut-like shape. The temperature of the doughnut shape (torus) is heated to a point above the recrystallization temperature and placed over a mandrel or idler. Charles E. Larson and Sons, a manufacturer of open die and seamless rolled ring forgings, is committed to providing products and services that meet or exceed our customer requirements.Our unparalleled capacity affords flexibility in meeting or exceeding production lead times. SHAPING THE NEEDS OF AN INDUSTRY WORLDWIDE 06 CUSTOM CRAFTED PRODUCTS Since 1890, Specialty Ring Products (SRP), the premier source for forged, seamless rolled rings and shapes, has consistently met the most demanding, high-stress needs of clients in aerospace, defense, bearing and other industrial applications.

Seamless Rolled Ring Rolled Ring Steel Cromdane Steel, Inc

EXPERTISE & EXCEPTIONAL QUALITY Backed by the resources of Scot Forge and Frisa, Ringmasters has led the seamless rolled ring industry with a diverse product offering, exceptional quality, a culture of continuous improvement and fast turnaround. Quality & Certifications Rolled Rings View Capabilities View OEMs View Industries View A seamless rolled ring is made in a three-step process, directing grain flow in tangential and radial directions to provide the pieces with strength, ductility, and resistance to impact and fatigue. When it comes to rolled rings, basic shapes with rectangular cross-sections are the norm. The seamless rolled ring forging process starts with heating a pre-cut billet, then the malleable metal is placed on a hammer or press. The ring shape begins with a centerpiece "snapped" from the pre-form to produce a hollow center, similar to a donut, and moved to the ring mill. The seamless rolled ring forging process begins by cutting a desired material's starting stock to size before rounding it on the open die presses. The rounded piece is then upset and then pierced to make a preform. The preform is a donut-shaped forging ready to be placed on a ring rolling mill. On the ring rolling mill, there are axial rolls.

OpenDie Seamless Ring Rolling Independent and Alloys

What is Seamless Rolled Ring Forging? In this blog post, we'll look at seamless rolled ring forging what it is, what it's used for, and the industries in which you'll find it.. Seamless forged rings are created through a process called ring rolling, which uses a machine called a rolling mill.The rolling mill can generate rings of a range of diameters and weights. How to reduce machining expenses for rolled ring forgings? This pdf document provides a comprehensive overview of the advantages, applications, and design considerations of this versatile process. Learn how to optimize your ring rolling process and achieve high-quality products with minimal waste.

Small or large quantities of open die or rolled rings Up to 252" maximum O.D. Up to 49" maximum face height Rolled ring weights to 60,000 lbs., open die weights to 300,000 lbs. Downstream processing such as heat treat, testing, machining, segmenting, parting or splitting can all be performed in house Guaranteed delivery programs Seamless Rolled Ring Forging Process. This section will assist you in understanding the seamless rolled ring forging process, product and terminology of forgings. Hover over each step to learn and see more of our process! McInnes Rolled Rings. 1533 E 12th St Erie, PA 16511. 1.800.569.1420. ABOUT. OUR TEAM; DOCUMENT CENTER; TESTIMONIALS;

Rolled Ring What Is It? How Does It Work? Seamless

"We can produce seamless rolled rings or contoured rolled rings up to 200 inches in outside diameter and custom forgings up to 40 feet long or 80,000 lbs.," said Weiss. All Metals & Forge Group has been manufacturing and selling open die forgings and seamless rolled rings for more than 50 years. What Are Rolled Rings Used For? Custom rolled ring forgings can be used in applications such as valves, bearings, clutches, ring gaskets, flanges, machines, and many more. They are often needed in some of the most demanding industries including automotive, oil & gas, mining, and heavy-duty manufacturing.