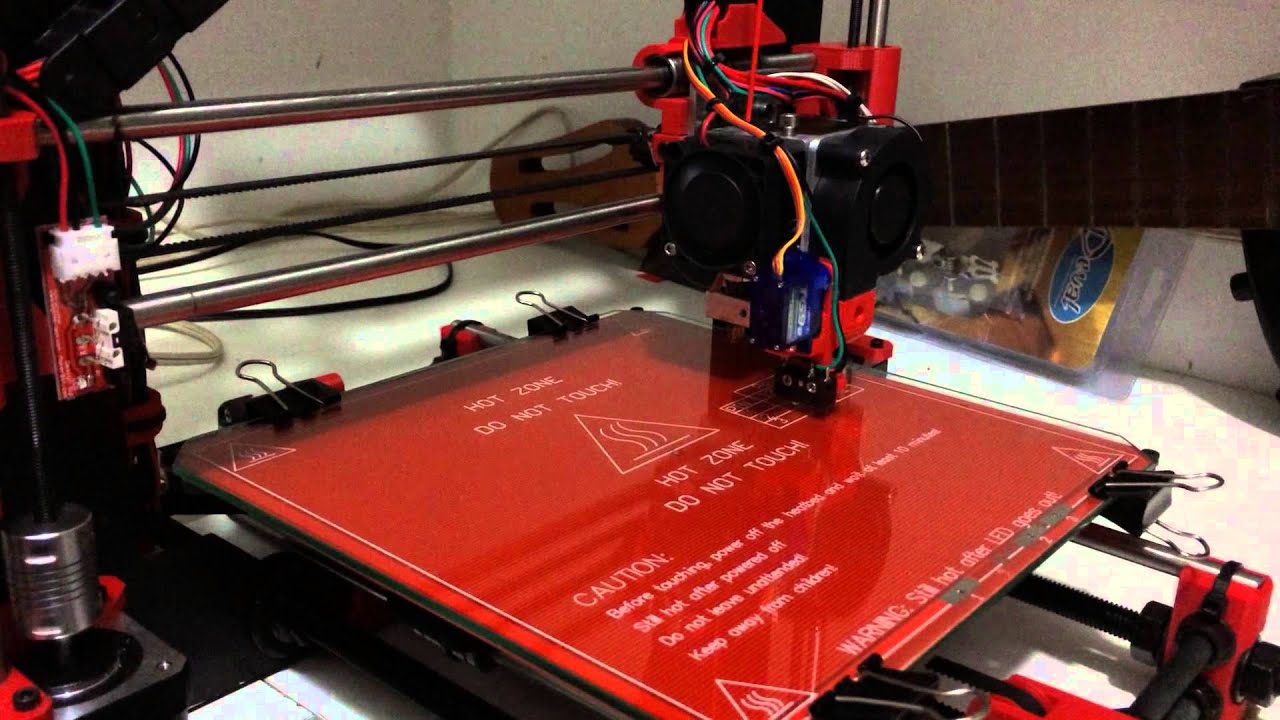

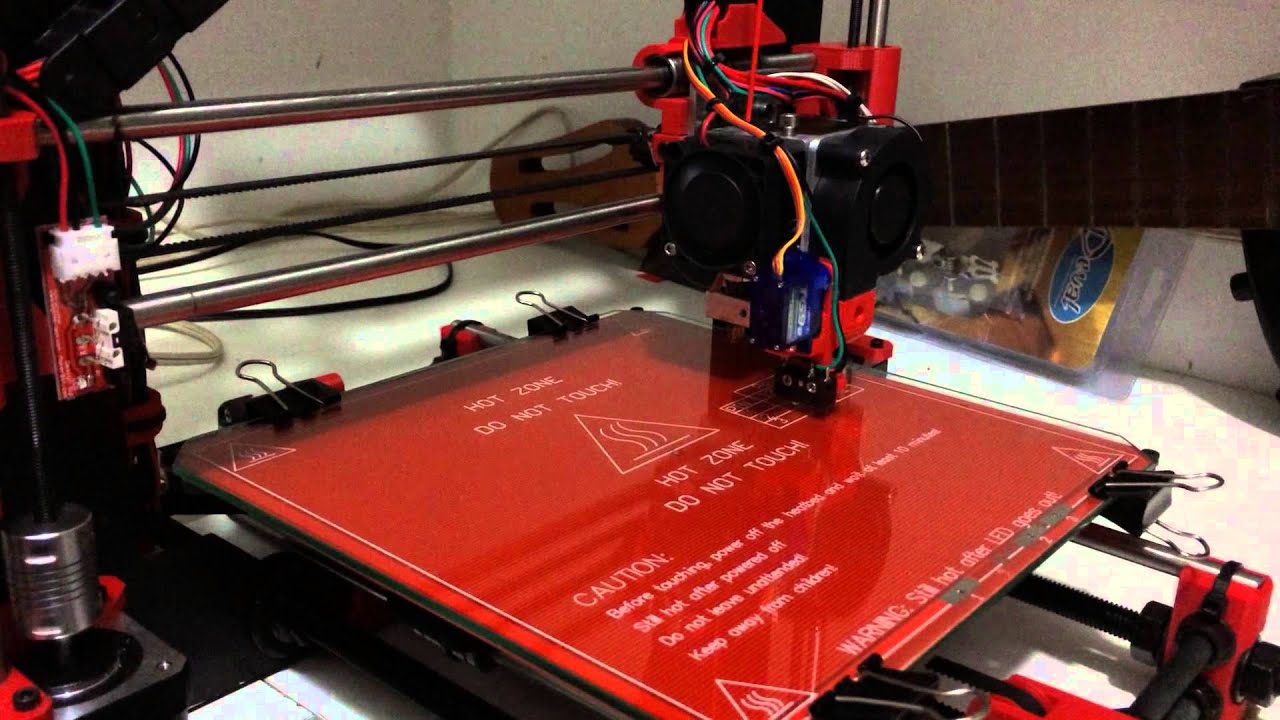

How the bed leveling works with a servo, no more calibrating the bed to start a print.It goes at 9 point of the bed and check the Z height and then when it p. See how to install the bed auto leveling system using an servo motor and an endstop. What is the bed auto leveling feature? This feature will use a sensor to measure the distance between the nozzle and the bed, on 3 or more points (up to 32), assuring you the perfect bed leveling and adehesion. See this video to understand how it can be useful!

flsun i3 2017 servo bed leveling YouTube

The popular BLTouch probe emulates a servo but uses a retractable pin. There are infrared and inductive probes that trigger at some known distance from the bed.. And if you have an LCD and enough program memory, you should also enable LCD_BED_LEVELING to add a Bed Leveling sub-menu to the LCD. Configure the points (for 3-point leveling) or. I also own the Prusa i3 wood and have installed auto bed leveling using a servo controlled probe. It's simple yet effective. The software will figure out the angle of the bed by probing 9 times. V. Implementing Auto Bed Leveling. Auto leveling can be added via: Integrated systems pre-installed by the manufacturer like on a Prusa MK3S+. No retrofitting needed. Third party add-on probe modules containing inductive, capacitive, optical, or servo probes.; Enabling sensor leveling in firmware like Marlin if probe hardware is already installed. Demonstration of auto bed leveling on Tevo Tarantula using a SG90 servo and mechanical endstop. A 'modular' servo mount is available to use with any printer..

Bed Leveling Servo Assembly For Guider 2/2s 3d Printer Parts 3d Printer Parts

Its mission: to explore strange new ways of leveling a print bed. So far, we've had servo probes, Allen key probes, Z-sled probes, inductive and capacitive contactless switches, just to name a. Demonstration of a Auto Bed Leveling procedure. Ramps 1.4, Micro Switch. (Yes, I know I still need to finish off a cleaner bracket for the servo arm). Automatic bed leveling is the next killer feature that will be found on all commercial filament printers.. this is a solved problem. In fact, it exists with a servo on the current Wilson 2. The servo motor is outside the enclosure and retracts the probe pin by pulling on a steel string inside a spring guide tube. Microswitches are known to work at high temperatures (that's what the link above uses), but usually need a servo or other mechanism to extend/retract them when needed.

Auto Bed Leveling with SG90 Servo and mechanical Endstop Switch YouTube

With this command you can also find the correct values for the servo angles.After homing your X and Y-Axis (G28 X0 Y0) and running the auto bed leveling process you cann use G1 Z0 to lower the nozzle onto the bed. If the Nozzle is to far away from your bed, lower the value, if the nozzle crashes into your bed, raise the value. BLTouch is an auto leveling sensor for 3D Printers that can precisely measure the tilt of Bed surface. It could work with any kinds of bed materials, such as glasses, woods, metals, and so on. Features Main functions and controls of BLTouch are the same as usual auto bed leveling sensor, consists of RC servo and micro switch. Thus, BLTouch can.

With this command you can also find the correct values for the servo angles. After homing your X and Y-Axis (G28 X0 Y0) and running the auto bed leveling process you cann use G1 Z0 to lower the nozzle onto the bed. If the Nozzle is to far away from your bed, lower the value, if the nozzle crashes into your bed, raise the value. The basic idea being that if you had 4 servos (one for Nopheads Genius Z Probe and three continuous servo's for levelling, you should in theory be able to automatically adjust the levelling of the bed, and alter the bed Z height, taking much of the pain away from the bed-height calibration issues that plague many people.

Auto Bed Leveling Prusa i3 Hephestos GT9 Servo Motor YouTube

There are four hand-turn screws beneath the bed of the Ender-3 Pro, one under each corner. Gently move the print head so its nozzle is positioned above one of the hand-turn screws. Slide a piece. Printer is a very bare bones noname china i3 diy kit with a heated bed i bought back in 2017, no sd slot, buttons, display or even adjust wheels for bed level, just a bolt+nylock nut in each corner. Other than that its just power and usb. The ability to affect overall z level just by turning a screw in or out is nice imo.