slipstick: Or there is an alternative servo library which allows you to set the speed. If you use VarSpeedServo.h instead of Servo.h you can just change Servo.myservo to VarSpeedServo.myservo then myservo.write(pos) to myservo.write(pos, speed) where speed can vary from 1 (very very slow) to 255 (fast). The way I reduce the rotation speed of a standard servo is to just not rotate the servo as fast. Instead of changing the angle straight from, say, 0° directly to 90°, change the angle in small increments at the speed you want. Even better is to use a logarithmic or exponential acceleration / deceleration schema. Say you want to to from 0° to.

What is a Servo Motor How a Servo Motor Works (Control) Ettron

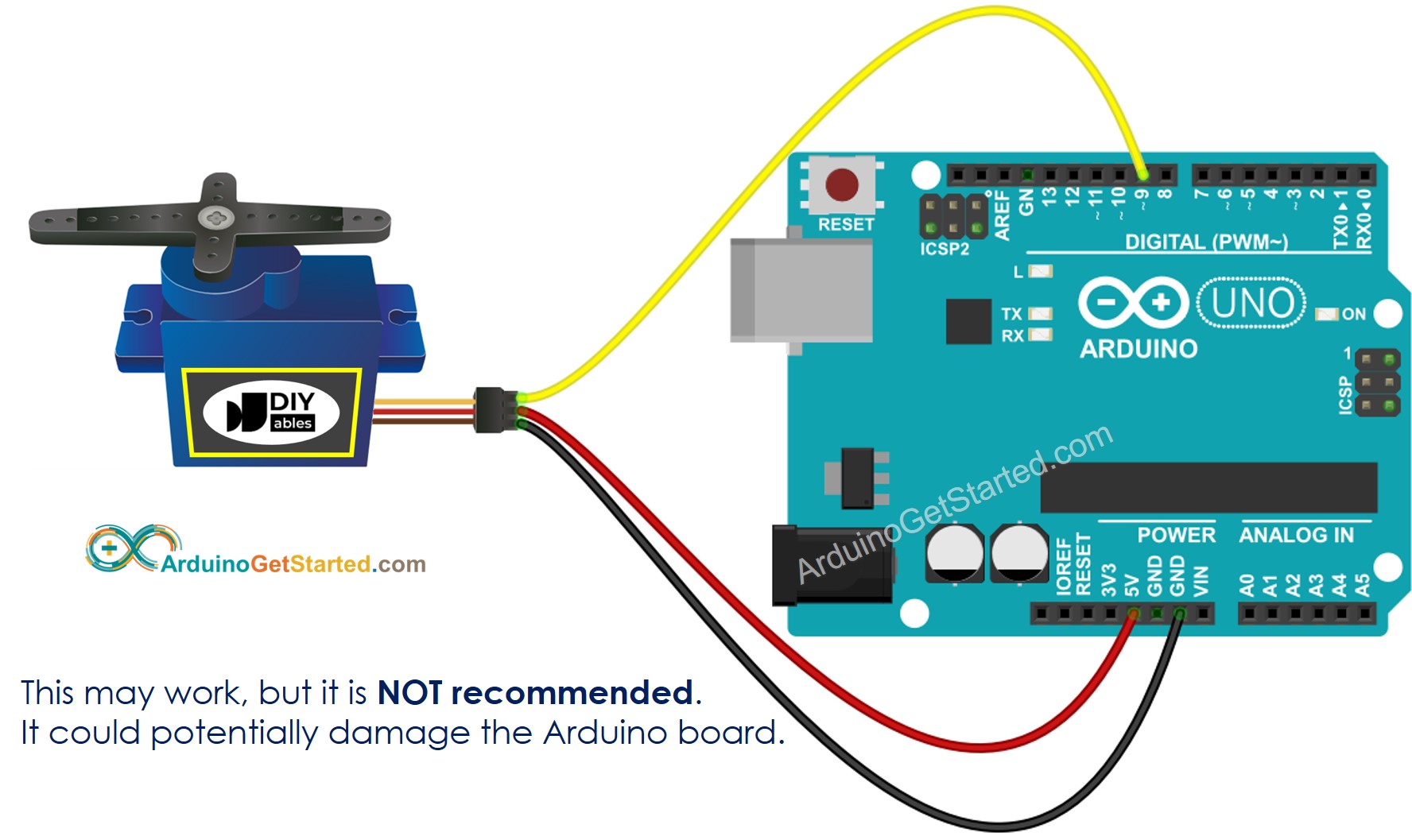

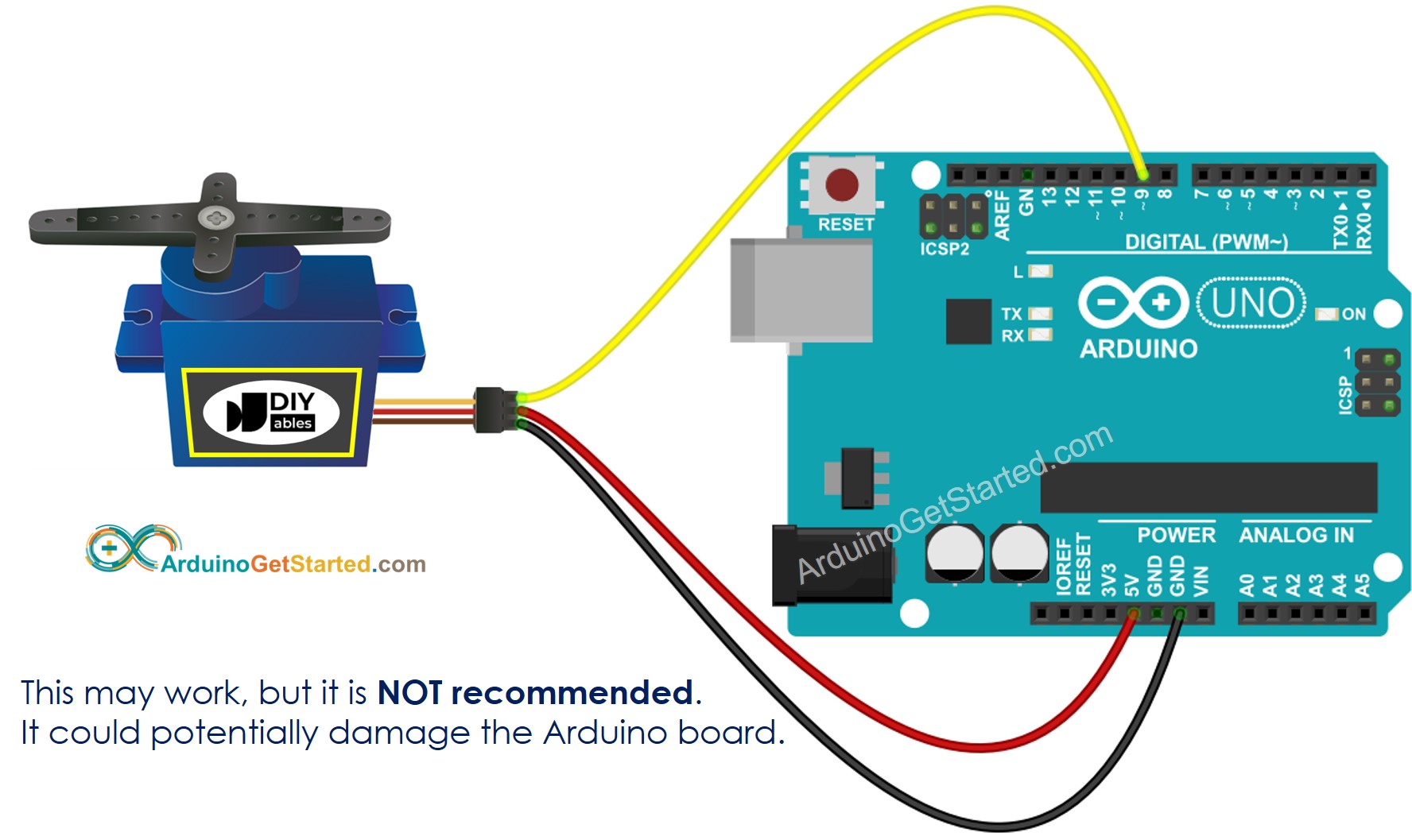

By using map() and millis() functions, we can control the speed of servo motor smoothly without blocking other code. The below example shows how to move the servo motor from 30° to 90° in 3 seconds. The servo's rotation speed is controlled by its internal circuitry. Once you send it a new target position, it drives at it's maximum speed toward that position and decelerates as it approaches. The best you can do to slow it down is to change its target stepwise, until you reach the target position, instead of setting the final target all at once. The Servo Library is a great library for controlling servo motors. In this article, you will find two easy examples that can be used by any Arduino board. The first example controls the position of an RC (hobby) servo motor with your Arduino and a potentiometer. The second example sweeps the shaft of an RC servo motor back and forth across 180 degrees. In this article, you will learn how to use a simple library to improve your servo motor controller sketches with minimal changes in your code. Happy 2024! Use coupon TECH2024 at checkout and get 30% Off Courses, Books, and Yearly Subscriptions!. // move the servo to 180, slow speed, wait until done myservo.write(0,30,true); }

MRW28 1 Way servo slow Model Radio

You truly can "Slow Down to Speed Up"! In our above example, slowing down the move time from 100 to 200 milliseconds will increase the MPS from 0.6 to 5.0 - an 800% improvement! The number of variables that determine the optimum move time are actually quite few - namely, the moving mass, the move distance, and the linear motor Newtons. Hi Guys, It's all about controlling the speed of servo motor using Arduino. In this video, you can learn how to run servo motor as well as control the speed. I am working on a project in which I need to change the speed of servo motors. The hardware I am using is an Arduino Mega 2560 board and I am using Servo.h library to control servos. Servo rotates from o to 180 degree. I am using 12 servo motors in the project and have to control them simultaneously. Is there a way? import mods for your servo. From picozero import Servo From time import sleep. set pin. Ser = Servo(0) set some prams for Servo. Min = 5000 Mid = 15000 Max = 25000. start in right place. Ser.set_servo(15000) move really slowly can change the prams this takes it down in single incruments #of 10000 to get to 5000 from 15000.

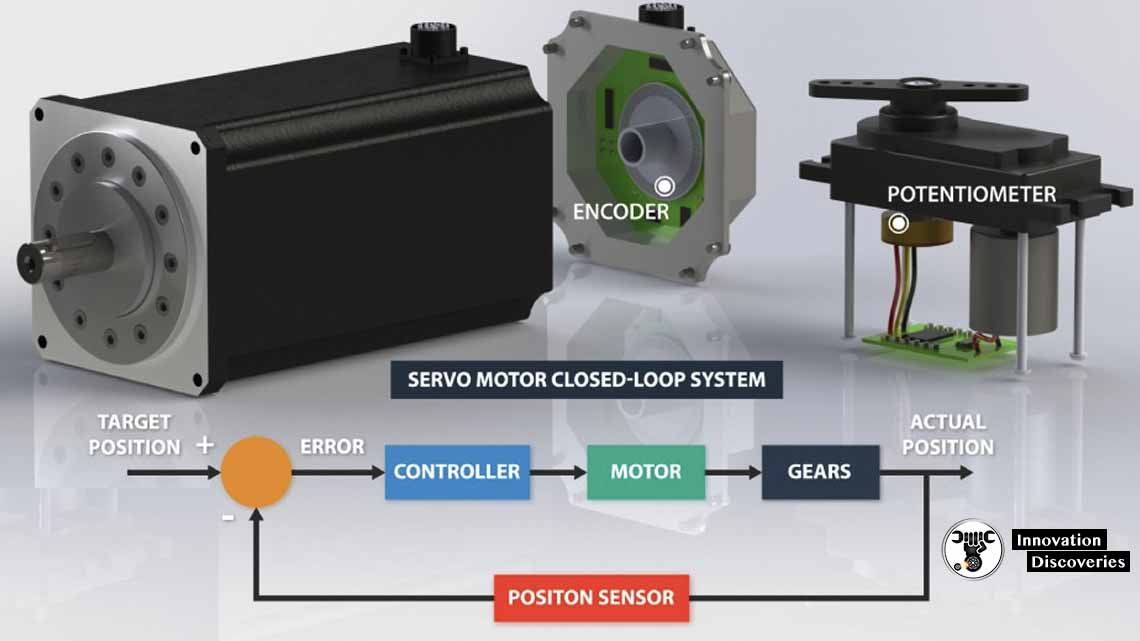

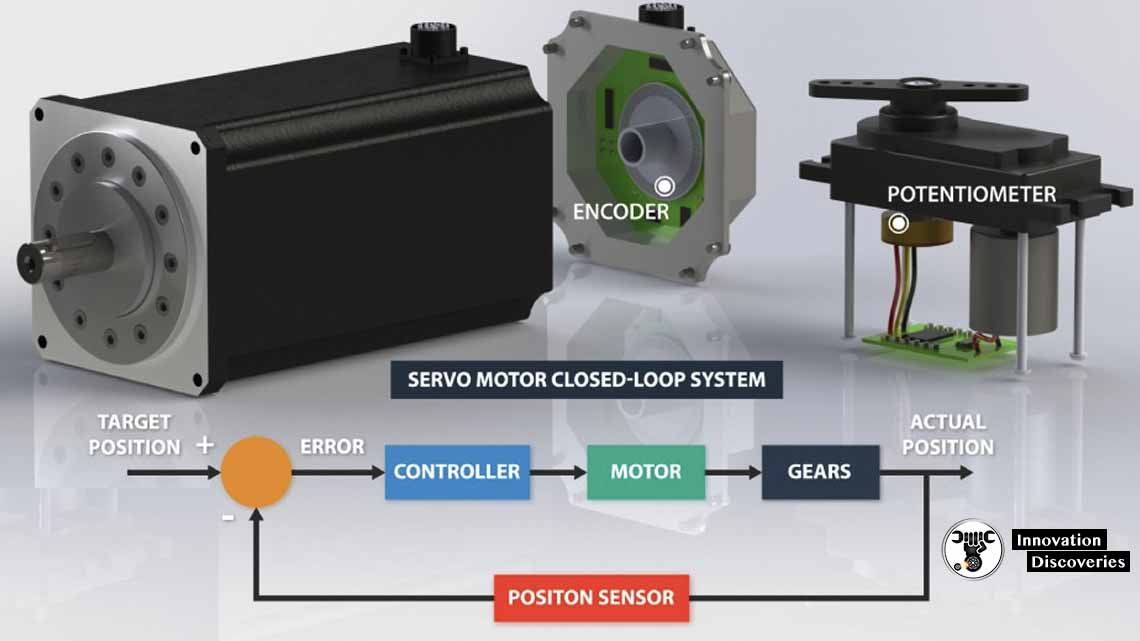

What is Servo Motor and its Types?

The way I think speed to a commanded position is controlled is by taking small steps (say 0.5 to 2 uS) at various rates. For example, if the step was 1uS and the rate was one step per 20 milliseconds, moving from a position of 1.5 mS pulse width to 1.8 mS pulse width (i.e., 300 uS change in pulse width) would take 6 seconds. A continuous rotation servo (sometimes referred to as a full rotation or just 360° servo) behaves more like a standard DC motor. Instead of controlling the position of the servo, the controller sets the speed and direction of the motor. Continuous rotation servos work well as drive motors or other applications where you need to control the speed and direction of a motor with just a few wires.

More links, graphics, and other extra information about servo motors follows.. They come in many shapes, sizes, and configurations—from large slow-speed, direct-drive rotary torque motors to sleek, compact units with low rotor-inertia for optimum acceleration and deceleration of loads, to frameless motors, to linear motors providing high. The datasheet shows that at 4.8V the servo can move 60° at a speed of .21 seconds without any limiting force factors (load). Also operating at 4.8V, this servo motor can drive a load up to 3.3kg/cm (Stall Torque). At 6V, the high end of the test voltage, the servo can move 60° at a speed of .16 seconds with no load, and has a higher torque.

Arduino Servo Motor Arduino Tutorial (2022)

I am currently working on a project for a charity display. The project I am working on envolves servos, I have pieced some code together but need to slow the servo down. The circuit involves a push button switch that that is supposed to go from 0 to 90 degrees when pressed and when let go, back to 0. Im not sure how to slow the servo down whilst keeping the button working any help would be. Most "cheap" servos start at 200-300 rpm and have a 70mm pulley. To slow down the motor far enough you may install a larger hand wheel instead of a speed reducer. I do not know of any "cheap" (meaning 100-200€ / GBP range) servo motor in the EU hemisphere that is extremely slow at the start and has a good amount of torque at slow speed.