A booster pump is a machine which increases the pressure of a fluid. It may be used with liquids or gases, and the construction details vary depending on the fluid. A booster pump acts like an intermediary between the water source and endpoints like taps, faucets, and showers. A booster pump takes in water from the source and pressurizes it to get the desired pressure at the endpoints. Generally, booster pumps are not the only devices used to move water within a system.

Booster Pump EBARA PUMPS BY ATS

Booster pumps are devices used to increase the pressure of existing fluid flow systems. They are designed to help pumping systems achieve higher flow rates and overcome high system head. Typically, booster pumps are used in water systems or applications that have low waste contamination. A booster pump is a mechanical device that is used to increase the pressure of water or other fluids and improve the flow rate. The boost pump is also known as a pressure pump. It is a type of centrifugal pump because it uses centrifugal force and one or more impellers to pump the fluid. Step 3: Decide the Pump Size. When sizing a booster water pump for homes , measure the current water pressure against the amount of pressure the booster pump can provide. If you want to boost pressure from 25 psi to 40 psi, you will need a water pump capable of producing 15 psi. Once the specific requirements of the pump have been established. The 500 Horsepower John Deere engine comes standard on our booster pumps. These engines are reliable and half enough power to get the manure to where it needs to go. 19.5″ Cornell Hybrid MP Pump. The Cornell Hybrid MP pump allows you to pump in more volitile situations without causing extensive damage to your pumps. Hydro Engineering offers a.

DuraMAC 3/4HP Booster Pump 115V (20 GPM Max) Booster Pump Systems & Parts

Engine driven booster pumps are equipped with electronic ignition, low flow shut-off, high temp blow off valve, fuel & air filters, muffler, choke and throttle to protect your investment and for safe operation. Download a Booster Pump Brochure below for detailed information on each model. Get Operator & Part Manuals. View booster spec sheet. March 11, 2022 Post Views: 1,552 What is booster pump and how does it work? What is a booster pump? Booster pumps increase low water pressure and flow. It provides the extra boost needed to raise your water pressure to the desired level. The main components of the booster pump unit are: Diesel Engine: Make Mitsubishi S12R-MPTK . Power: 940 KW at 1600 RPM. Gear Box: Masson - MMW 5700 ratio 1: 3,133.. The main components of the booster pump unit are: Ellicott 20-inch dredge pump . Ellicott close-coupled reduction gear box . Caterpillar 32 Tier 4 Final industrial diesel engine. Natural Gas Sweetening. Saeid Mokhatab, William A. Poe, in Handbook of Natural Gas Transmission and Processing, 2012. 7.3.4.2 Pumps. The amine reflux and booster pumps are normally centrifugal, inline, or horizontal pumps. Seal systems are an important consideration on the reflux pumps when treating H 2 S gases, as seal failure will result in H 2 S emissions. . Selection of the circulation.

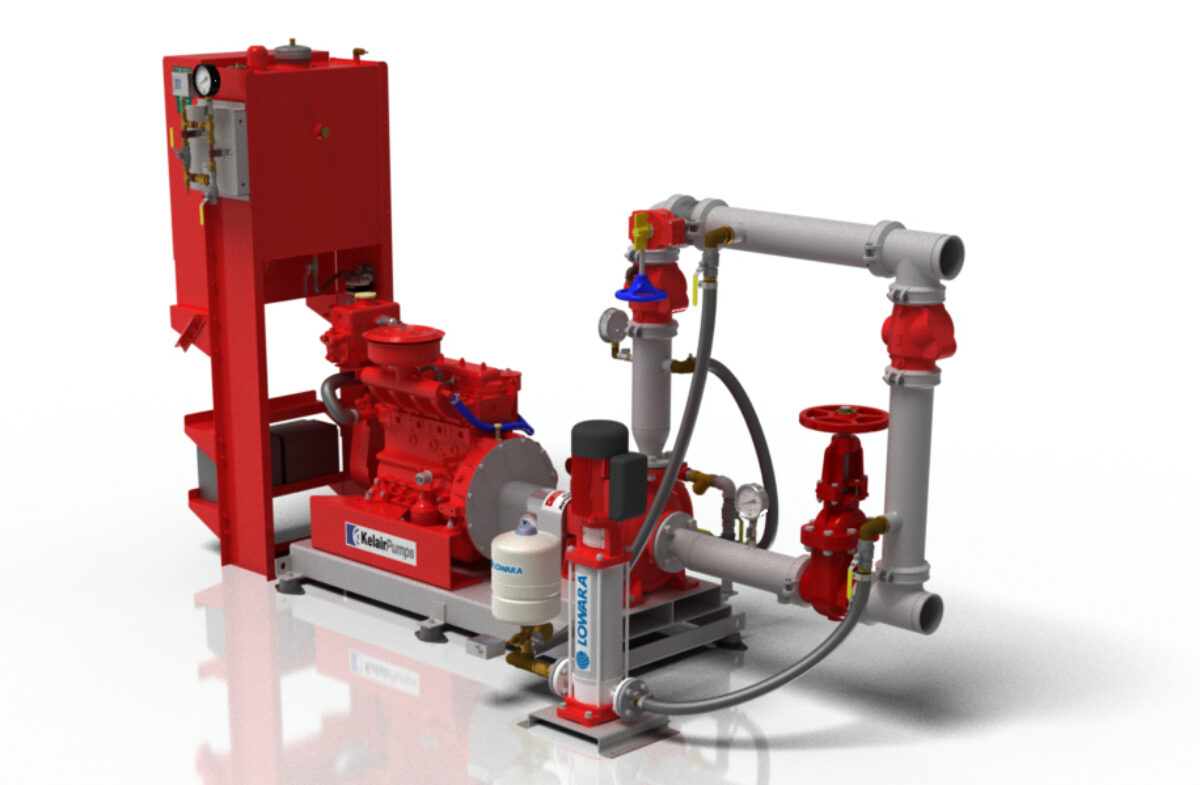

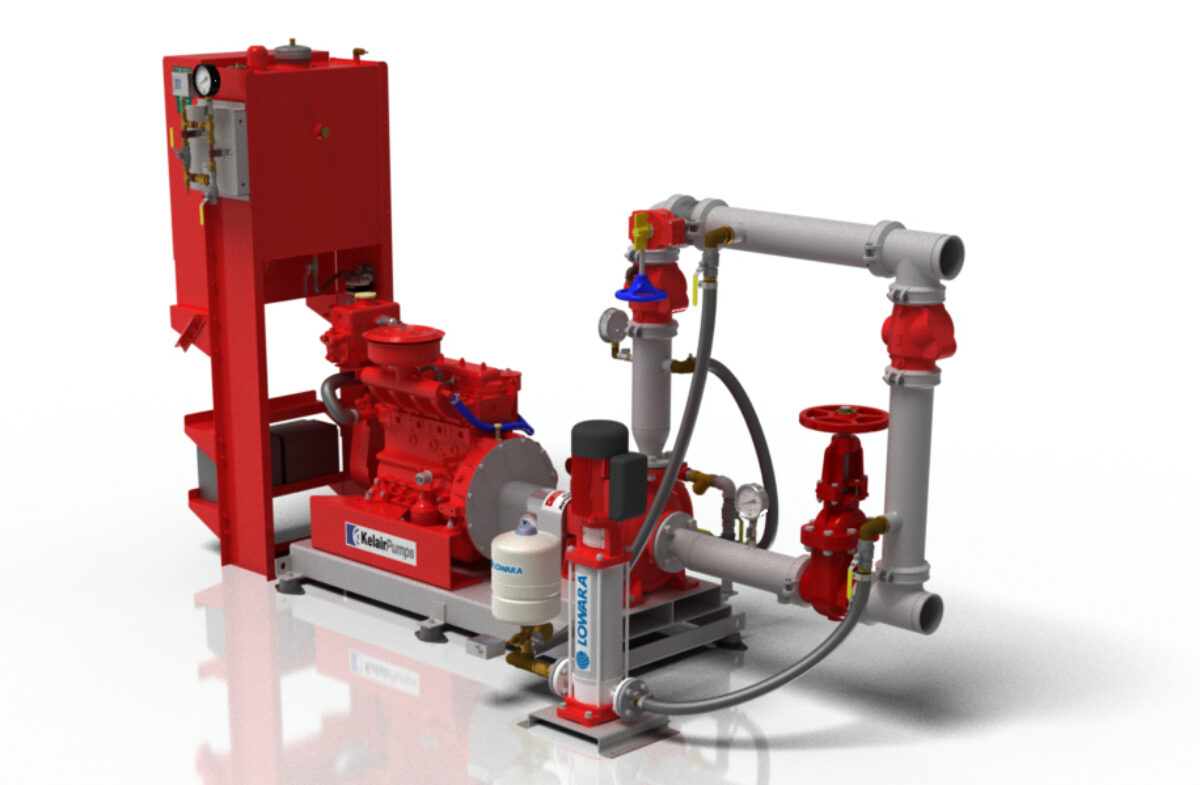

Diesel & Electric Hydrant Booster Pumps Kelair Pumps Australia

Eaton offers the commercial industry's largest pump portfolio for widebody aircraft, including boost pumps used in all industry segments. Pumps are available in all installation types: cartridge/canister, in tank, inline, and input power AC and fixed and variable frequency DC. The new generation of booster pump trailers features merged hydraulic systems to eliminate the need for two separate reservoirs. The feeder capability has also been upgraded, as the Warthog package offers hydrostat transmission to run a secondary feeder pump and steel tanks contain low point crossover.

Grundfos' range of booster pumps offer a variety of water pressure solutions, from a basic and reliable solution to intelligent pump control that will automatically adapt to varying inlet pressure and overall water consumption in the home. So, you can ensure optimal comfort for your customers with the pump that best suits their needs. 5. The Overall Size and Weight of the Pump. The size and weight of the water pressure booster pump is also important, especially if the pump needs to be portable. Larger pumps will typically be more expensive and require a reliable power source. It is important to select the correct size for the application. 6.

BOOSTER PUMP

Supercharging with booster pump: If boost pressure exceeds 10psi, adding a booster pump to a 60lb fuel injection system is a popular option. Acting like a boost-reference regulator, as boost intensifies, the booster pump generates more fuel pressure and flow. Its augmented fuel delivery is triggered by an increase in voltage output (16, 18, 20. GP2500 Self Priming Gear Pump. With a 100% Duty cycle the GP2500 is capable of self priming and moving even sludgy engine coolant. The brass construction makes this pump resilient and reliable with low maintenance requirements. Available in 12volt dc with a length of only 208mm (8.2″), GP2500 is the perfect for mobile and stationary applications.