CENTRIFUGAL COMPRESSOR - OVERHAULING PROCEDURE FOR CENTRIFUGAL COMPRESSOR OVER HAULING PROCEDURE FOR BARREL TYPE COMPRESSOR: Proper safety clearance getting from concerned operation remove coupling spacer from driver, turbine or motor. remove coupling by use of coupling puller like hydraulic puller or special tools. Who is this guide for? Pump operators and plant engineers. The objective of this guide: This article will give you the required knowledge on how to operate a centrifugal pump smoothly and how to overhaul it. Centrifugal pumps are used in several industries for transferring liquids from one point to another.

CENTRIFUGAL COMPRESSOR OVERHAULING PROCEDURE FOR CENTRIFUGAL

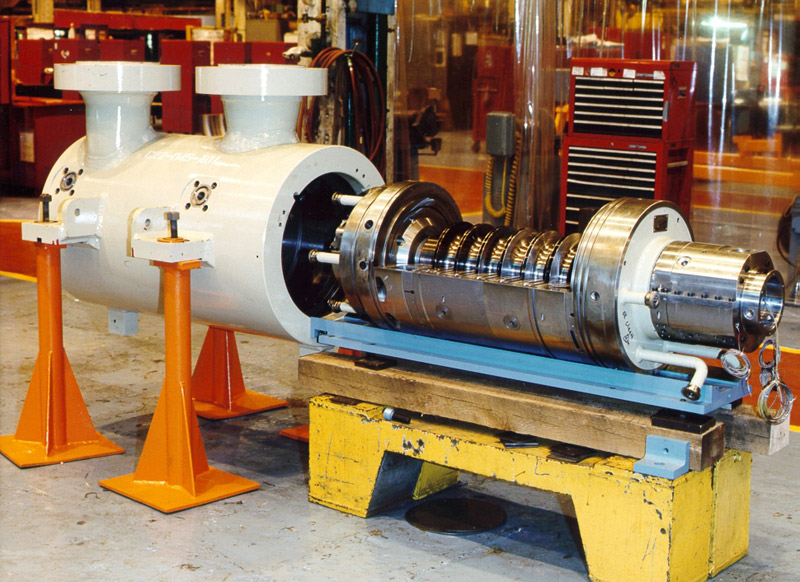

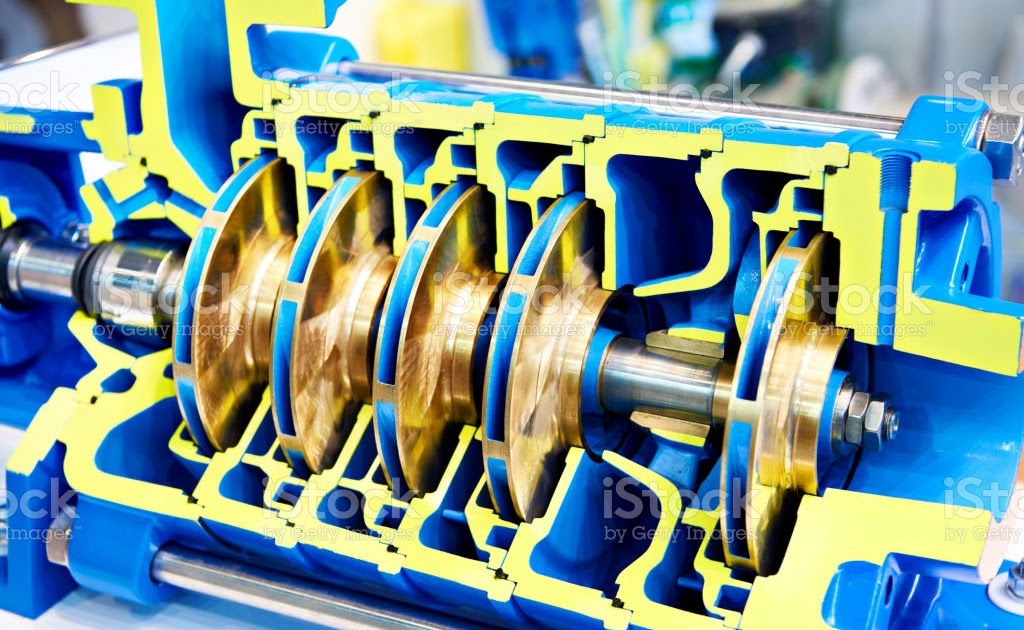

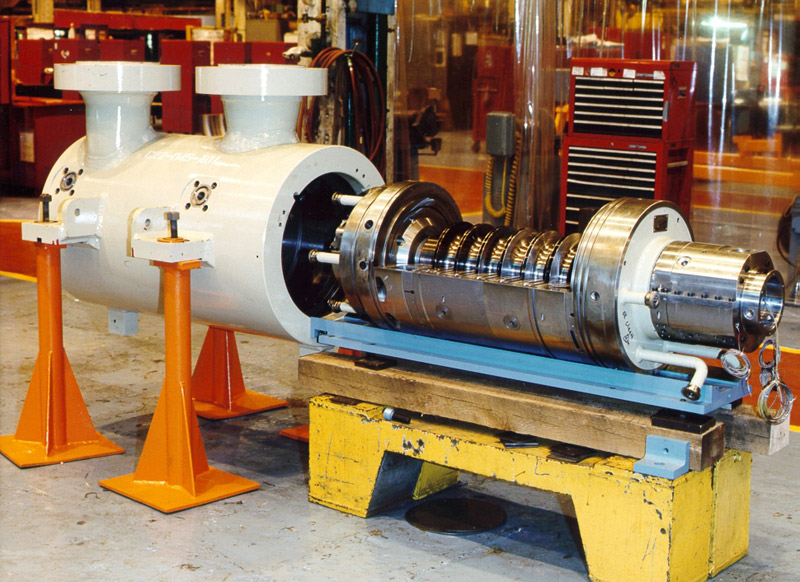

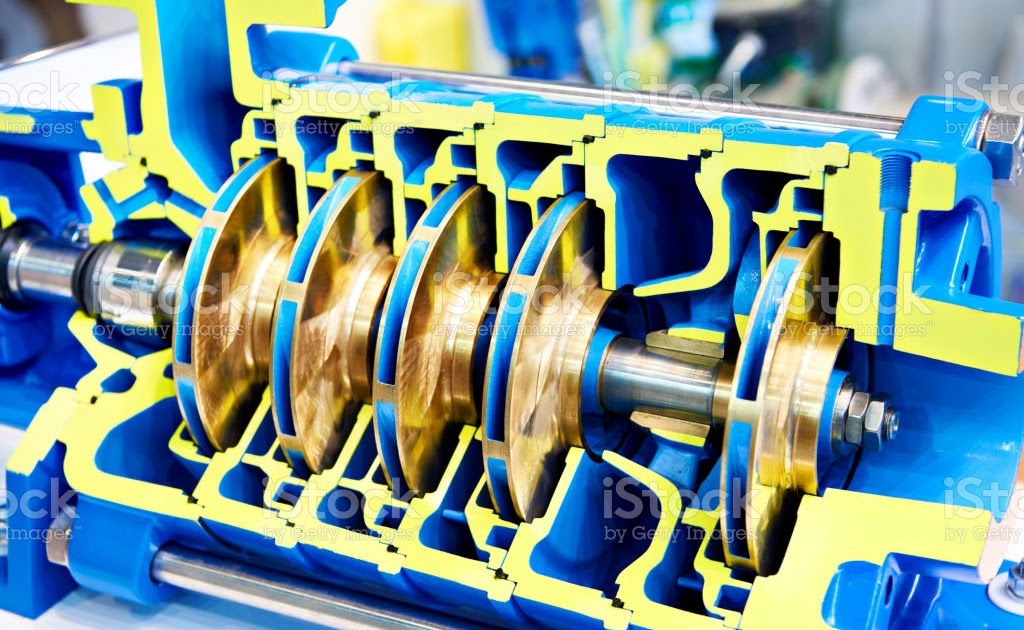

0:00 / 23:14 Compressor | Centrifugal Compressor | Centrifugal Compressor Overhauling | Overhauling Procedure Oil Gas World 31.4K subscribers Subscribe Subscribed 3K Share 295K views 3. in which a centrifugal compressor can be built and usf:d t.o satisfy a customer's operating and maintenance requirements. TYPICAL l\WLTJSTAGE CO.MPHESSOR DESIGN A typical multistage centrifugal compressor, de signed to meet a particular customer's needs, is shown in Figure l. This machine consists of impellers m i APPLICATION CHART This chapter contains sections titled: Compressor Start-Up Risks Generic Start-Up Procedure Centrifugal Compressor Start-Ups Reciprocating Compressor Start-Ups Screw Compressor Start-Ups 1.6 Centrifugal pumps 12 2 Centrifugal Pumps: Design and Construction 19 2.1 Introduction 19 2.2 Impellers 19 2.3 Pump casings 25 2.4 Wearing rings 31 2.5 Shaft 34 2.6 Stuffing boxes 35 2.7 Mechanical seals and seal housings 38 2.8 Bearing housing / bearing isolators 52 2.9 Couplings 56 3 Pump Hydraulics 63

2BCL306A Centrifugal Compressor Overhauling Overhauling Procedure

During the centrifugal compressor overhauling procedure, the compressor is disassembled, and each component is inspected for any signs of damage or wear. Any worn-out or damaged parts are replaced, and the compressor is then reassembled. Once the centrifugal compressor overhauling procedure is complete, the compressor is tested to ensure it is. axial and centrifugal compressors follows the API 670 Standard for Machinery Protection Systems. Management Solution - The recommended management solution for centrifugal compressors includes the protection solution with the addition of System 1* trending and analysis software. The table above shows recommended protection transducers on a The special aerodynamic design of the diaphragms in the centrifugal compressor allows for the suction gas to be conveyed to the impeller without forming a vortex. ⚙️. Centrifugal compressors typically have two journal bearings and one thrust bearing, with tilting pad journal bearings being commonly used for efficient performance. 🔍. in this video you will learn about back pullout centrifugal pump overhauling procedures like dismantling, inspection and assembling.components of centrifugal.

CENTRIFUGAL PUMP OVERHAULING PROCEDURE FOE MULTISTAGE CENTRIFUGAL PUMP

rated compressors should maintain 22 to 25 psig of lubricant pressure. • Check for lubricant leaks. Every 40 Hours (or Weekly) • Be certain pressure relief valves are working. • Clean the cooling surfaces of the intercooler and compressor. • Check the compressor for air leaks. • Check the compressed air distribution system for leaks. TWO OVERHAUL OPTIONS - REMANUFACTURE OR REBUILD The rebuild approach to overhauling an air compressor typically takes place in the field, at the customer site, where the compressor is already installed. The product testing after the rebuild occurs in the field and may include checking discharge pressure, vibration levels and testing for oil leaks.

Periodical Maintenance [Overhauling] Every component of the centrifugal chiller plays an important role. In an extended period of usage, deterioration continues due to rotation, heating, cooling and vibration at parts that cannot be checked during daily/periodical checks. If the maintenance of the components is ignored, it may lead to accidents. Elliott compressors and turbines installed in the 1940s and 1950s are still in operation today, either as originally supplied or upgraded to handle new. Elliott's multi-stage centrifugal compressors lead the industry in both performance and reliability. Increased Aerodynamic Efficiency

Centrifugal Compressors Overhauling Chiller Point Air Conditioning LLC

When an air compressor needs to be overhauled, you hope the experience will be as pain free as possible. There are different approaches to overhauling an air compressor, and each has different implications related to cost, parts, service and performance. How to Know When it's Time to Overhaul an Air Compressor Knowing when to overhaul a unit is important, and there are certain signs that. CENTRIFUGAL COMPRESSOR 9 CCI - Introduction (LOL) 9 CCR - Refresher (LOL) 9 CCO - Operator (LOL) 10 CCM - Maintenance LOL 10. Stopping procedures . Compressor behaviour at changing process conditions . Operating limits reciprocating compressors . Condition Monitoring subjects . Lube oil .