Go to the new parallel breakout board to get more information and the wiring diagram. cnc electronics - main power supply Share Watch on Beginning with only one driver and motor eliminates most of the complexity that typically scares the timid folks out there. But first, the power must be establish. FANUC CNC control units, as shown in the configuration diagram in Chapter 2, and supplies additional information on using these components with the Series 0i/0i Mate. Refer to individual manuals for the detailed specifications of each model. The models covered by this manual, and their abbreviations are:

Cnc Breakout Board Wiring Diagram

5 axis cnc breakout board step dir en +5v 24vdc com step dir en +5v b+ b - a+ a - driver board step dir en +5v 24vdc com step dir en +5v b+ b - a+ a - driver board step dir en +5v 24vdc com step dir en +5v b+ b - a+ a - driver board step dir en +5v in1 x axis limit nema 23 stepper motor x axis y axis z axis a axis x axis n.c. com parallel cable. 1、Unit select。 Select unit:on menu"config"—select native units--- select MM. BlueSky_TEC Mach3 5 axis CNC interface board (BL-MACH-V1.1) instruction 2、Ports and pins: (1)、Port setup and axis selection:note--make sure you have save your changes. (2)、Motor outputs:set as the below diagram。 32MP Control Wiring. 4th Axis Servo Options. Chip Conveyor. CNC 88-32MP E-Stop Circuit. DC Chassis WD. ELE-2064 Diagram. EMC.pdf. Fadal Servo Coolant Wiring Diag. Fadal Wiring Diagrams. GE Fanuc 18i Wiring Diagram. Hall to Reed Sw Conversion. Legacy WD. Legacy Wiring Diagrams. Miror plug wiring. Options. Pendant. Probes and Scales. Servo Turret. 1.1 Introduction. The latest upgraded 5 axis breakout board is specially designed for the CNC single axis 2-phase stepper driver controller, such as M542, M542H, MA860H, 2M542, 2M982, DM542(A), DM860(A) etc. single axis stepper driver controller series. With this 5 axis breakout board, any 1-5 single axis stepper driver controllers can be.

Milly Cole Wiring Usb Cnc Mach3 Rnr Wiring Diagram Manual Pdf

The PDF includes: Wiring diagram for old YooCNC controller; Wiring diagram for the new controller as described in this article; MPG wiring; Parameter settings for the VFD; Parameter settings for the DDCS Controller; GX16 connector wiring (stepper motors) From the mains plug one of the leads is going to the main power switch. fanuc wiring diagram 5.11 e350_drives cnc control wiring detail. september 2005 18 of 38 fadal machining centers 5.12 e400_spindle amp drive wiring detail wye-delta. 19 of 38 man_0128_r1 fanuc wiring diagram 5.13 e450_servo amp drive wiring detail for x, y, z axis. september 2005 20 of 38 Learn how to install and configure Mach3Mill, the software that controls your CNC machine, with this detailed PDF guide. Find out how to set up the printer port, the motor tuning, the inputs and outputs, and more. Note: The below wiring diagrams are examples, any input can be used for the connections. Note. The bellow wiring diagrams require setting the inputs to use pull-down resistor. 8.1 Connecting Switches or push button. Wiring diagram to connect switches 8.2 Connecting NPN sensors. Wiring diagram to connect NPN open collector proximity sensors

Electrical diagram of the CNC Machine. * Pinout details are given in

block diagram. d. es0121. nts. 5. machmotion 14518 cr 7240 rolla, missouri, usa 573-368-7399 machmotion.com. operator pc. note: all functions may not be present or available as shown. refer to user manual. motion controller spindle drive axis drive axis drive axis drive internet ethernet #1 spindle control cable axis encoder cables note. 0-10V signal. GND +5V GND +5V V-V+. AD AP +5V ZD ZP +5V YD YP +5V XD XP +5V. motor driver. motor driver. motor driver X motor driver. stepper motor stepper motor stepper motor stepper motor.

DrufelCNC - software for controlling CNC machines. Read more: https://drufelcnc.com NOTICE OF LIABILITY Using any CNC machine is a dangerous operation. All precautions must be taken, as the machines may turn on at any time, the software MAY malfunction at any time, any user of the Software must understand and take this into Step 1 Suggested cable lengths Cable lengths included in the kit assume that the controller will be installed at the back of the machine. You may need to source different lengths of cable if you have other plans for controller placement. Your kit ships with 2 long length cables, one with 3 conductors, one with 4 conductors.

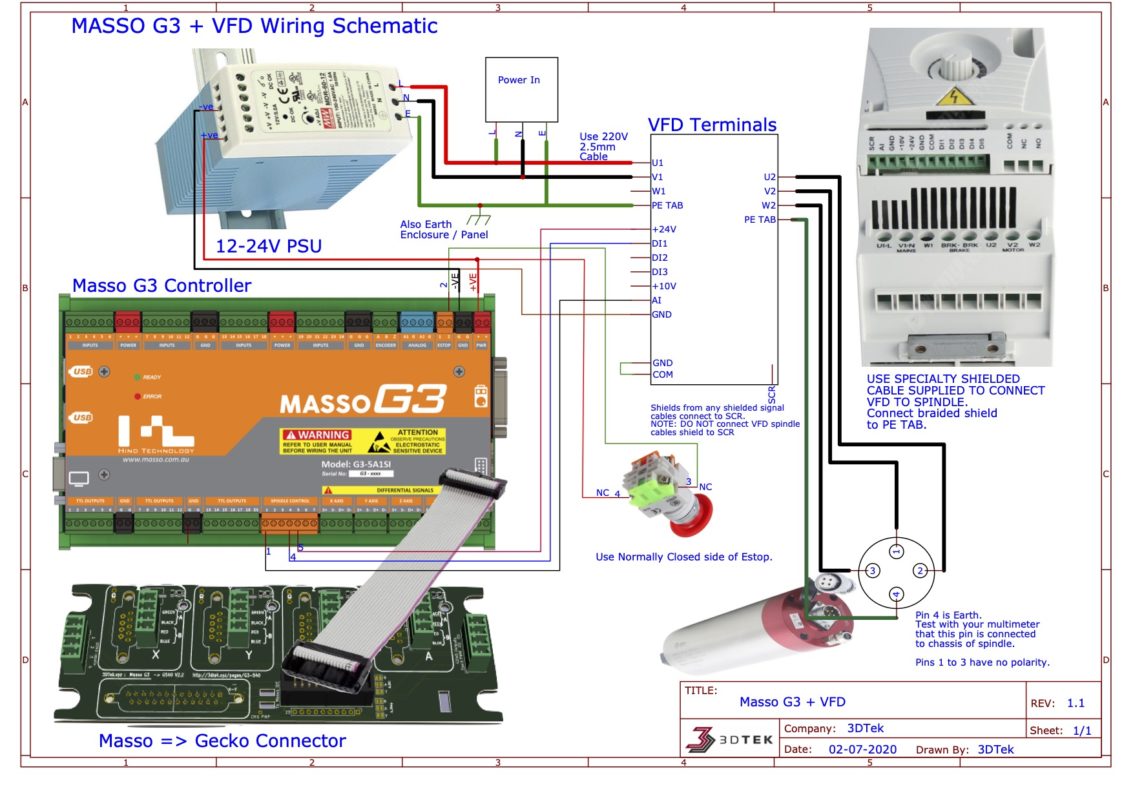

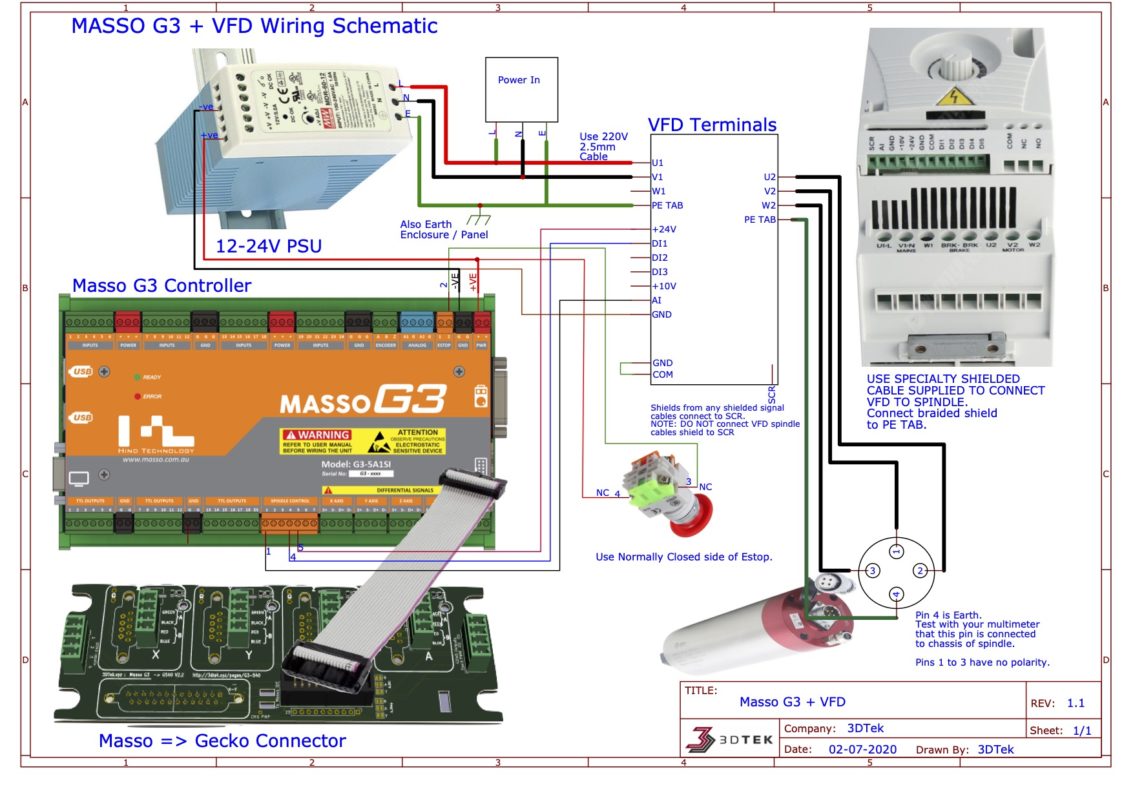

Masso (GEN3) Wiring Diagrams. CNC Routers 3DTEK

Miscellaneous CNC Documents. - Solid Model files for OAK, ALLIN1DC, PLCADD1616, DC1, ADD4AD4DA, Encoder Expansion Board. zip file. - CNC console dimensions and mounting examples. - CNC Standard Electrical Cabinet M400/M39/T400/T39. - CNC Standard Electrical Cabinet M15 upgrade. TO GAIN ACCESS TO SW1 REMOVE OMI WINDOW AND LABEL. 2.INSTALL FOLLOWING ELEMENTS ON 1100-1 BOARD: FUSES AGC-2 - F10, F29, F40. SOLID STATE RELAYS (BLACK) - K16, K31. CIRCUIT BREAKER 2.5A - CB1 3.TO ACTIVATE THE PROBES USE THE FOLLOWING COMMANDS: MP12 PROBE - M64, M66 TS 27 PROBE - M65. OMI.