Common rail direct fuel injection is a direct fuel injection system built around a high- pressure (over 2,000 bar or 200 MPa or 29,000 psi) fuel rail feeding solenoid valves, as opposed to a low-pressure fuel pump feeding unit injectors (or pump nozzles). Diesel common rail direct injection (CRDI) and its benefits Common rail is a fuel injection system found in modern diesel engines. Common rail systems provide a level of flexibility which can be exploited for class leading emission control, power and fuel consumption.

CRDi Common Rail Direct Injection Technology Explained Crankit

Common Rail Direct Injection (CRDi): Most modern engine fuel systems use an advanced technology known as CRDi or Common Rail Direct Injection. Besides, both petrol and diesel engines use a common 'fuel rail,' which supplies the fuel to injectors. Furthermore, manufacturers refer to this technology as CRDi in diesel engines. The main difference between common rail and direct injection diesel fuel systems lies in their method of fuel delivery. Conventional diesel fuel systems use a mechanical pump to deliver fuel to the engine, while common rail systems use a high-pressure pump to deliver fuel directly to the injectors. Common Rail Direct Injection or CRDI System: working, advanatages November 30, 2019 by EnggStaff There are two different types of injection systems in the diesel engines or compression ignition (C I Engines). One is the Air Injection System and another one is Airless or Solid Injection System. Common rail injection allows the combustion process to be optimized so that less pollutant is produced from a smaller amount of fuel. Friedrichshafen, Germany With common rail fuel injection, the combustion process can be optimized to achieve low pollutant levels combined with lower fuel consumption.

Why Choosing Common Rail for a Gasoline Direct Injection (GDI

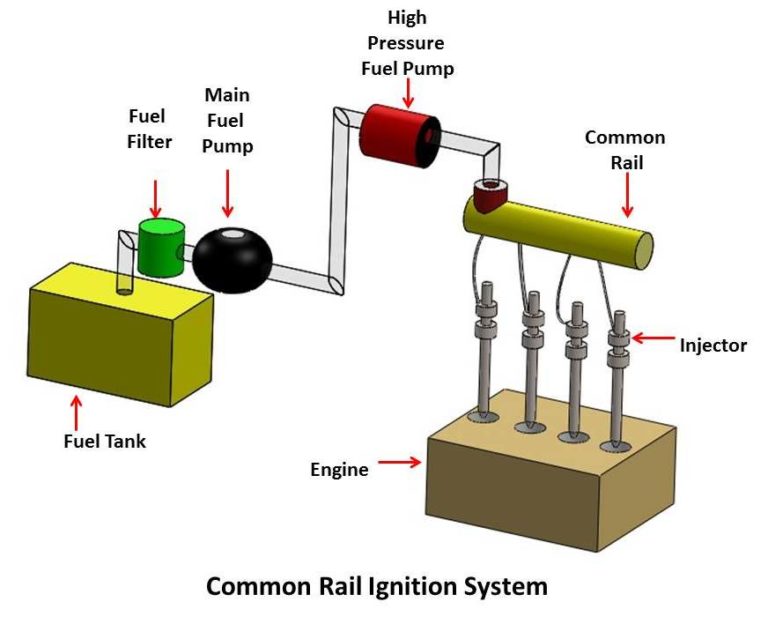

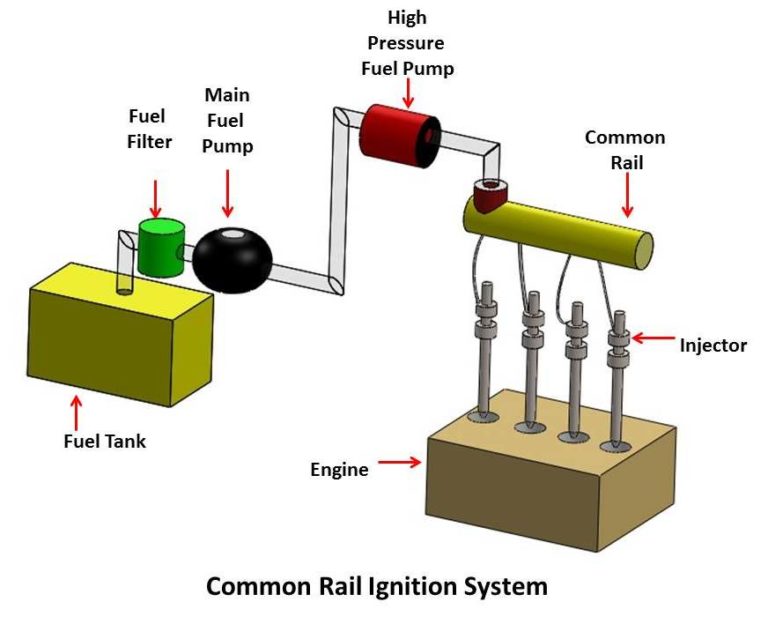

The Common Rail Direct Injection (CRDI) system is a cutting-edge technology for diesel engines. It stores fuel at high pressure in a common rail, allowing precise and efficient fuel delivery to each cylinder. CRDI enhances combustion efficiency, reducing emissions, improving fuel economy, and delivering more power, making it a staple in modern. : In the common rail system, fuel is distributed to the injectors from a high pressure accumulator, called the rail. The rail is fed by a high pressure fuel pump. The pressure in the rail, as well as the start and end of the signal that activates the injector for each cylinder are electronically controlled. In this way, the common-rail system helps to raise specific power output, lower fuel con-sumption, reduce noise emission, and decr ease pollutant emission in diesel engines. Today common rail has become the most commonly used fuel-injection system for modern, high-rev passenger-car direct-injection engines. Design The common-rail system. Common rail direct injection system (CRDI): Common rail direct injection system is mostly used in modern diesel engines. In this type of injection system, the fuel is supplied to the injectors with the required pressure and further supplied to the cylinders for the combustion process.

Diesel common rail direct injection (CRDI) benefits DIESELO

A CRDi engine, short for "Common Rail Direct Injection" engine, is an advanced type of fuel injection system specifically designed for diesel engines. It has revolutionised the way diesel engines function, offering numerous advantages over traditional fuel injection systems. The common rail direct injection system is a modular design that has a common rail, electronic fuel pump, fuel tank, fuel filter, ECU, injectors and sensors. The fuel from the fuel tank is fed into the filter and then to the fuel pump. A high-pressure pump pressurises the fuel.

Mar 9, 2022 • 4 min read Photo by Olivier Cleynen / Wikimedia The modern version of the common rail injection system that is used in diesel engines was invented in 1990. This invention was built on nearly a century of advancements to the diesel engine. Common rail uses a high-pressure rail to deliver fuel to each solenoid valve. This is opposed to the traditional direct fuel injection system of using low-pressure pump nozzles to deliver fuel while producing more emissions. Related: Top 5 Advantages of Common Rail Diesel Injection 1) Lower Emissions 2) More Power 3) Less Noise 4) Fewer Vibrations

What is CRDI? Common Rail Direct Injection System Mech4study

Common Rail Direct Injection System. In CRDI system the fuel is distributed to the injector from a high pressure accumulator and through a rail and this rail is common to all the cylinder. Because of this, it is called as common rail injection system. The quantity of the fuel and atomization are controlled electronically using a programmable. The Past, Present, and Future of Diesel Performance. When high-pressure common-rail debuted on the LB7 Duramax back in 2001, it changed the way we look at diesels. Ultra-high injection pressure, solenoid-style, multiple-event injectors, and full electronic control over the system brought the most refined diesel performance we'd ever seen to the table—along with quieter, cleaner engine.