Cone Layout is a program to unfold a frustum of a cone and generate a sheet cutting layout or flat pattern projection that can be rolled or bend up into a truncated cone shape. Either side of the truncated cone can be tilted. To help you visualise the cone you are editing, a rotating 3D model shows the dimensions. Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at Large End, Tori Cone with knuckle radius at Both Ends.

Printable Cone Template

View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material. Text Top Width Base Width Height Cone Side Surface Area 33.55 in² (No top or base) Cone Total Surface Area 46.9 in² Cone Volume 21.99 in³ Cone Top Circle Area 0.79 in² Cone Base Circle Area 12.57 in² Cone Top Circle Circumference 3~5/32" Cone Base Circle Circumference 12~9/16" FULL Template Arc Angle 126.4 ° Template Outer (Base) Radius 5~11/16" Flat Top Cone Calculator Calculates measurements for a pattern to construct a flat top cone Length A (mm) Length B (mm) Length C (mm) Arc Angle = _ (degrees) Radius R1 = _ (mm) Radius R2 = _ (mm) Cone (truncated) A cone, optionally with the top cut off. (In that case, it's called a frustum ). Can be used to help create the geometry for a beaker, vase, party hat or lamp shade. If you'd like a real cone, just use 0 (zero) for the Top Diameter. Do not score or fold the glue flap in this template to keep the geometry at the seam smooth.

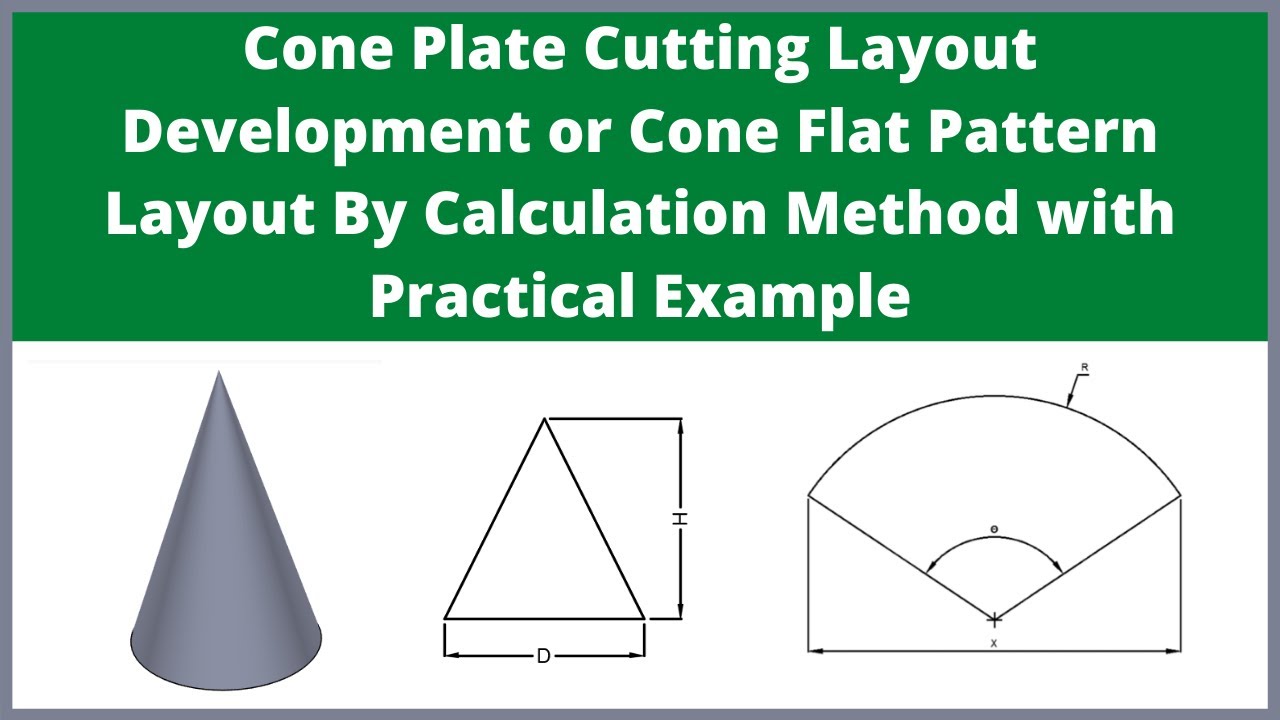

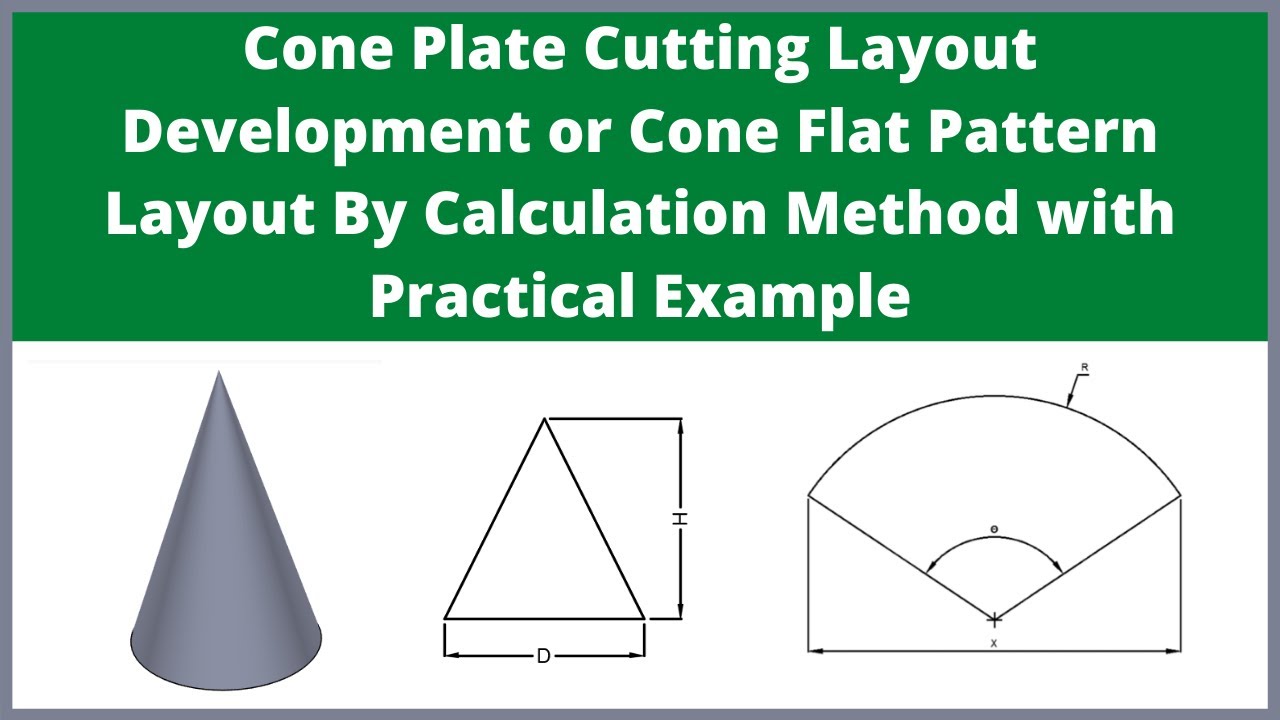

Cone Plate Cutting Layout or Cone Flat Pattern Layout by Calculation

Cone Final Layout. In this way we can develop fabrication Layout when we had problem like case-1 where Cone angle and Cone Diameter is Given. Now we will see Case-2 type problem of fabrication layout Development. Case 2: Cone Diameter and Cone Height Given. Step 1: Define Generalized Diagram for Full Cone Layout Development. CONES: The rules are simple. The layout radius is the length of the side of the cone. For truncated cones the lengths are to the theoretical point (c 1 + c 2 ). The FLAT layout angle is determined by the circumference of the finished cone divided by the circumference of the layout circle (from radius 1. above). Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is. First you must find the difference between the large and the small Dia. Multiply the large dia. by the vertical height, Divide this product by the difference first obtained large dia and small dia) Dec 30, 2023 11:41 PM EST Learn how to develop a cone following this step-by-step guide. Joaquin Corbalan | Canva Develop a Cone Step-by-Step How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps.

How to Develop a Cone Cone Development Owlcation

Cone development. Calculator of right circular cone / truncated right circular cone development. The calculator computes parameters of a right circular cone or truncated right circular cone development. The picture below illustrates the task. We have the lower base radius, radius of the upper base (in case of a truncated cone), and cone height. How to layout a cone Learn how to layout a cone and the for mula, these numbers can be replaced with your dimensions. The formula for the cone is… First you must find the difference between the large and the small Dia. Multiply the large dia. by the vertical height, Divide this product by the difference first obtained large dia and small dia)

Calculator Use. This online calculator will calculate the various properties of a right circular cone given any 2 known variables. The term "circular" clarifies this shape as a pyramid with a circular cross section. The term "right" means that the vertex of the cone is centered above the base. We can always depend on getting a finished product that is to our expectations or better.". David P., New York. The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need.

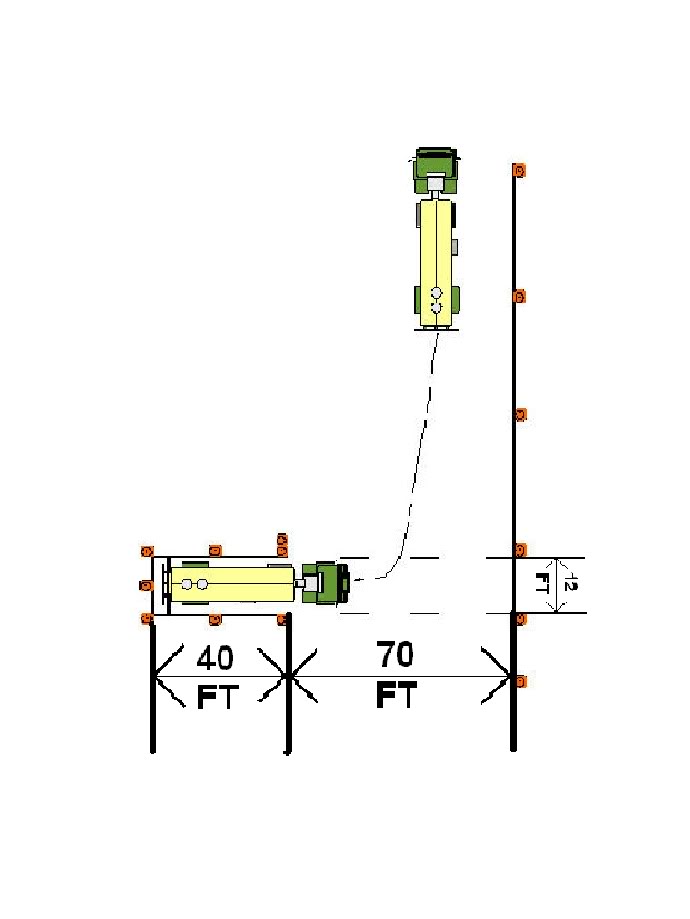

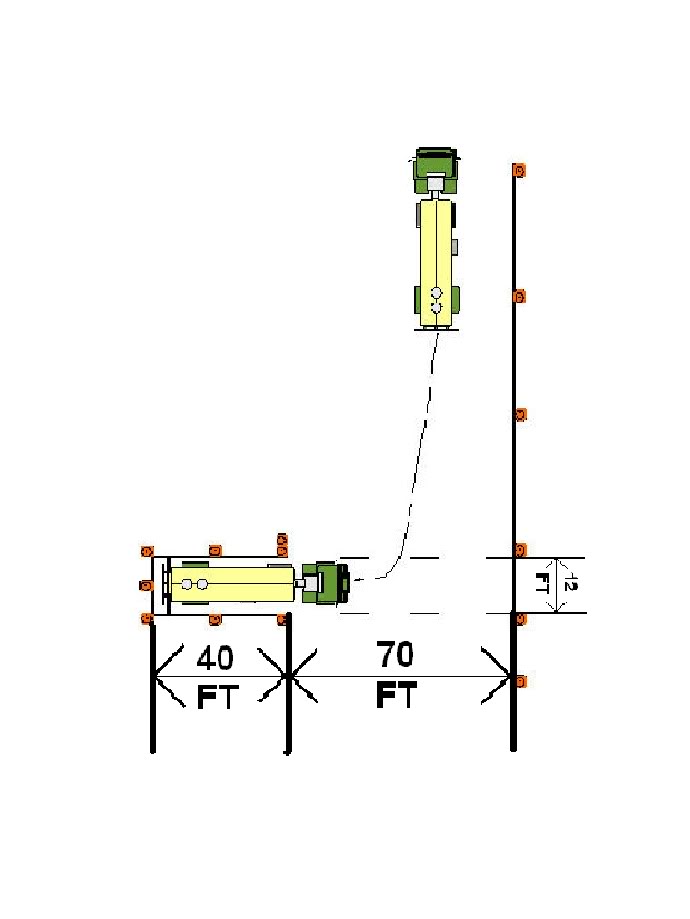

cdl skills test cone layout Big Rig Career

How to layout a cone pattern Johnathon Jensen 105 subscribers Subscribe Subscribed 78 Share 24K views 5 years ago There are many different ways to lay out this pattern. This is just one way and I. It is a cross section view. It has the possible dimensions labeled. You can choose Full cone or Half cone. Half cone would be helpful if you needed to make it in two halves and weld it together. Enter the desired dimensions of the finished cone shape. You only need to enter on diameter and two others five possible dimensions of the final cone.