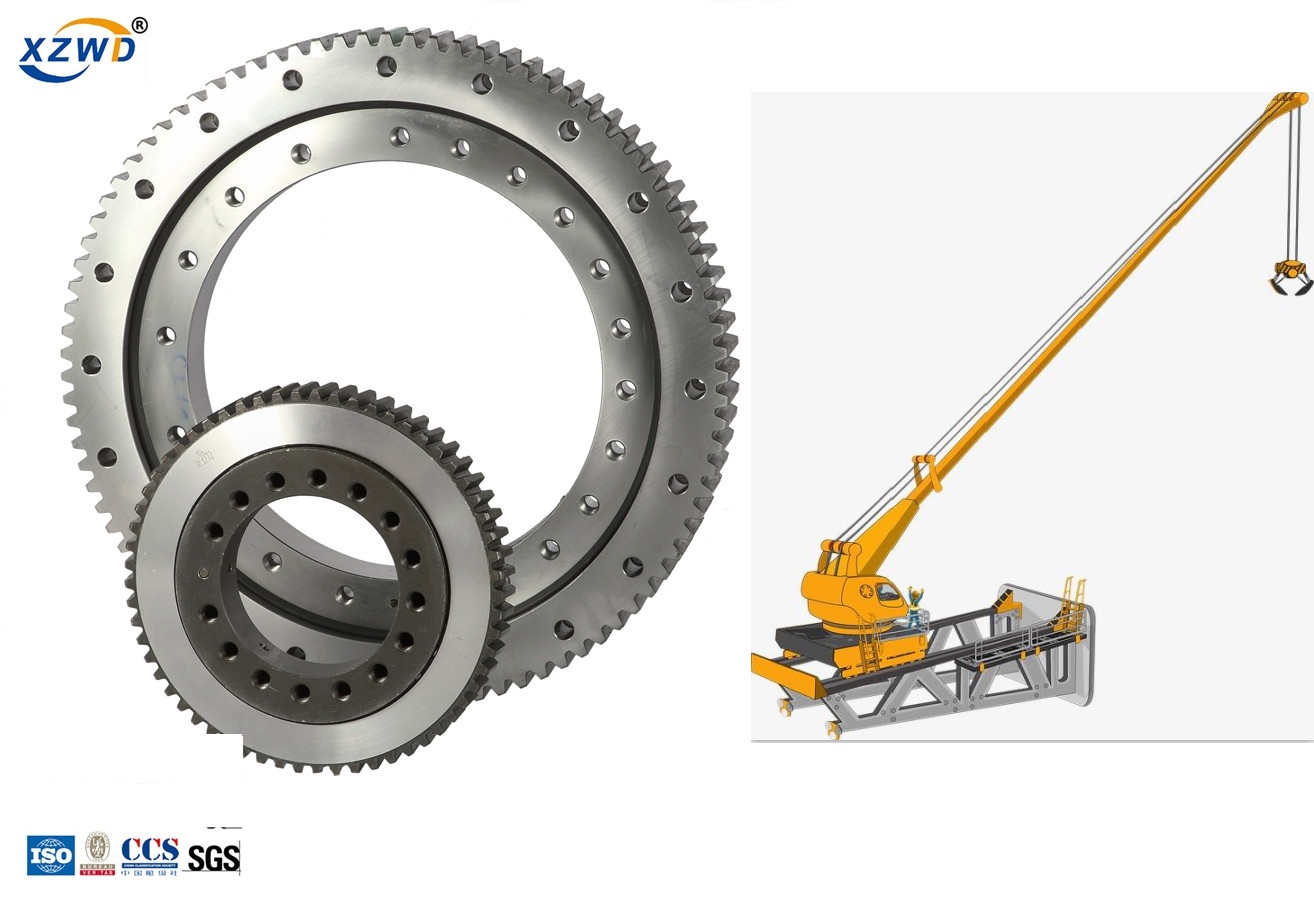

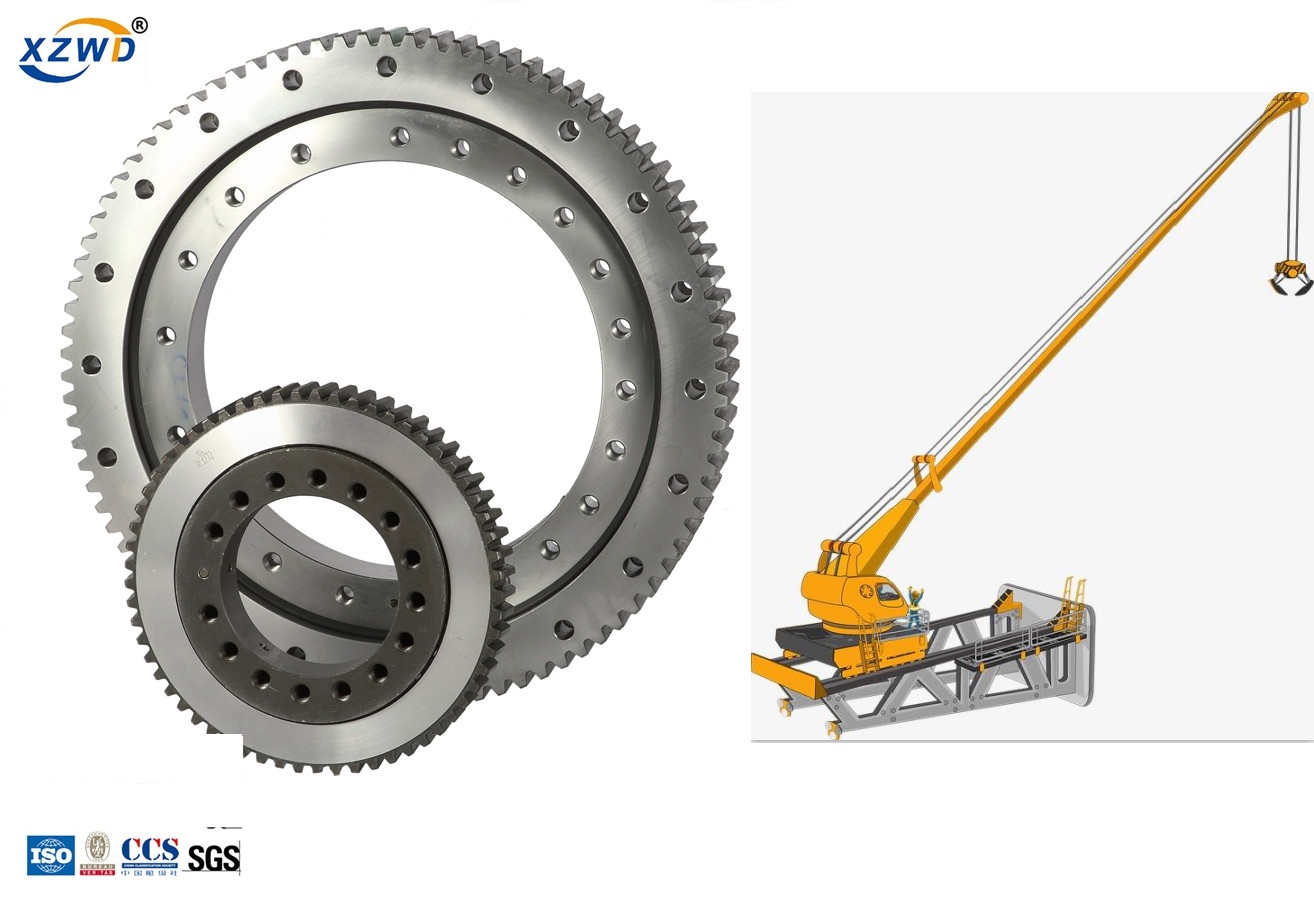

Slew rings play a critical role in crane operation due to their many responsibilities. While crane slewing rings regulate many movement types, they also withstand the weight of the equipment and its various loads, including payload and counterbalance. Types of slewing bearings Liebherr is one of the world's leading producers of large diameter bearings. Our portfolio comprises many different types, manufactured in a wide range of dimensions and designs. All of our slewing bearings can be manufactured with internal gears, external gears or without gearing.

Slewing Ring Bearings for Deck Crane (133.45.2500) China Slewing

a suitable syringe. If there are no sampling ports fitted, clean the outer seal next to the grease nipples closest to the four sampling locations; grease should be pumped into each grease nipple in turn without rotating the crane and the old grease expelled from the seal taken for analysis. Rocking Test October 15, 2021 Shizu Yamaguchi Slew rings have a few different names, including turntable bearings, slewing rings and slewing bearings. The purpose of slewing rings is to enable rotational motion between different components in a system (Ritbearing). That motion can be radial, axial or tilting. Top Slewing Bearing Manufacturer SlewMaster provides its customers with high-quality slew rings within a wide range of sizes used in many applications. Sizes range from 3" (100mm) up to 6 ft (2m) in OD. Slew Ring Price: Call for price Financial Calculator Item Location: Sanborn, New York 14132 Quantity: 2 Condition: New

Grove Slew ring AT 633 B / AT 528, Sassenheim, Netherlands Used crane

In this article from Crane and Rigging Hot Line, bearing remanufacturing manager Ronald Shaw describes the importance of scheduled raceway lubrication, torque checks on bolts, and gear lubrication. Download this article. A crane's critical connection: the importance of maintaining large slewing ring bearings in lifting equipment (Adobe PDF) Follow these steps to ensure proper slew ring installation: Check the equipment: Open the purpose-built box designed to transport and store the slew ring in an upright position. Make sure the bearing arrived pre-lubricated with anti-rust oil. Also, check that manufacturers put into place anti-slip and anti-vibration measures. A failure of the slew ring bearing would result in an operational breakdown that could end in catastrophe. Other potential outcomes of crane failures include increased replacement and maintenance costs for your business. Luckily, there are several ways in which you can assess and prevent potential failures from occurring. SLEWING RING SYSTEM CONTINUOUS ROTATION Turning endlessly. Effer slewing ring system allows the crane to rotate continuously. For the transport of oil and electrical signal from the base to the moveable part, Effer makes use of an innovative and reliable rotary distribution system which does not set limits to the crane's maneuvers in any way.

Cheap Tower Crane Slewing Ring Suppliers XZWD

ring or the outer ring can be useful to locate the bearing and improve gear mesh accuracy. A full circle of bolts on both the inner and outer rings is the best way to fasten a slewing bearing. Generally, the bolts should be SAE J429 Grade 8 or ISO 898-1, Class 10.9. The The PALFINGER Continuous Slewing Mechanism permits an unrestricted radius of action. The crane is rotated or 'slewed' using a gear box and hydraulic motor instead of a rack and pinion system. All endless slewing mechanisms come as standard with a high quality roller ball bearing.

Crane lubrication. Vibration, high mechanical loads, contamination and moisture are all threats to bearing service life. Like any mechanical system, slewing rings and bearings in deck cranes and pulleys on cantilever arms require proper lubrication to function optimally. SKF and Lincoln automatic lubrication systems deliver the exact quantity. Slewing bearing with crossed cylindrical roller bearing High stiffness and constant resistance to rotation Slewing bearing with triple row roller bearing Provide highest capacity for a given diameter Slewing bearing with wire race bearing 60% lighter compared to same-sized all-steel bearings Customized slewing bearing

Single Row Four Point Contact Ball Slewing Ring Bearings For Crane from

See more reviews for this business. Best Crane Services in Raleigh, NC - A+ Tree and Crane Services, Morlando Crane, Baysden Crane, Americrane, Mid-Atlantic Crane & Equipment, Dean's Wrecker Service, Bryant Industrial Crane & Rigging, Carolina Crane Corporation, All Carolina Crane & Equipment, Tapco Crane & Rigging. Tower crane slewing ring failure prevention measures and maintenance. The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of.