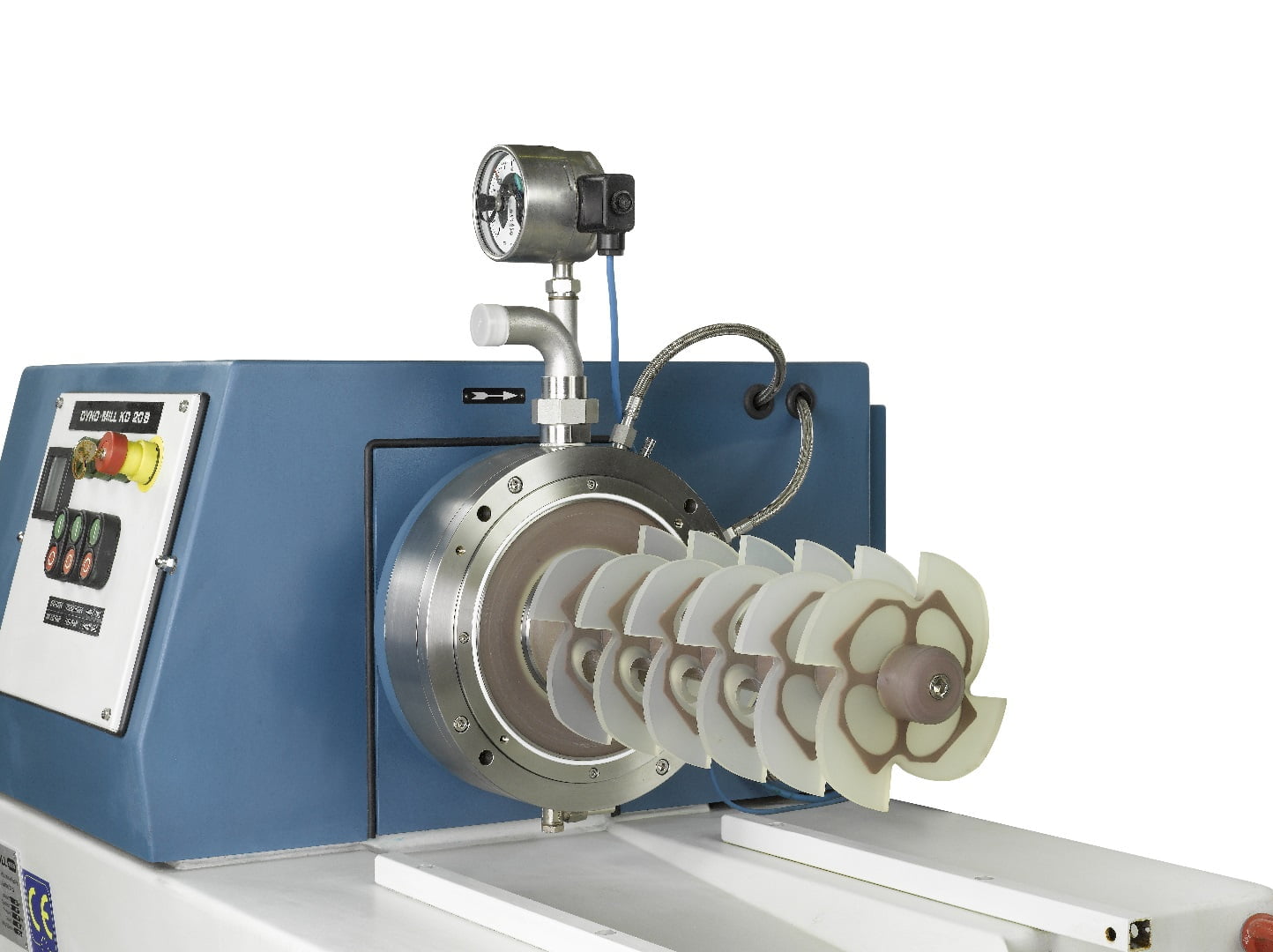

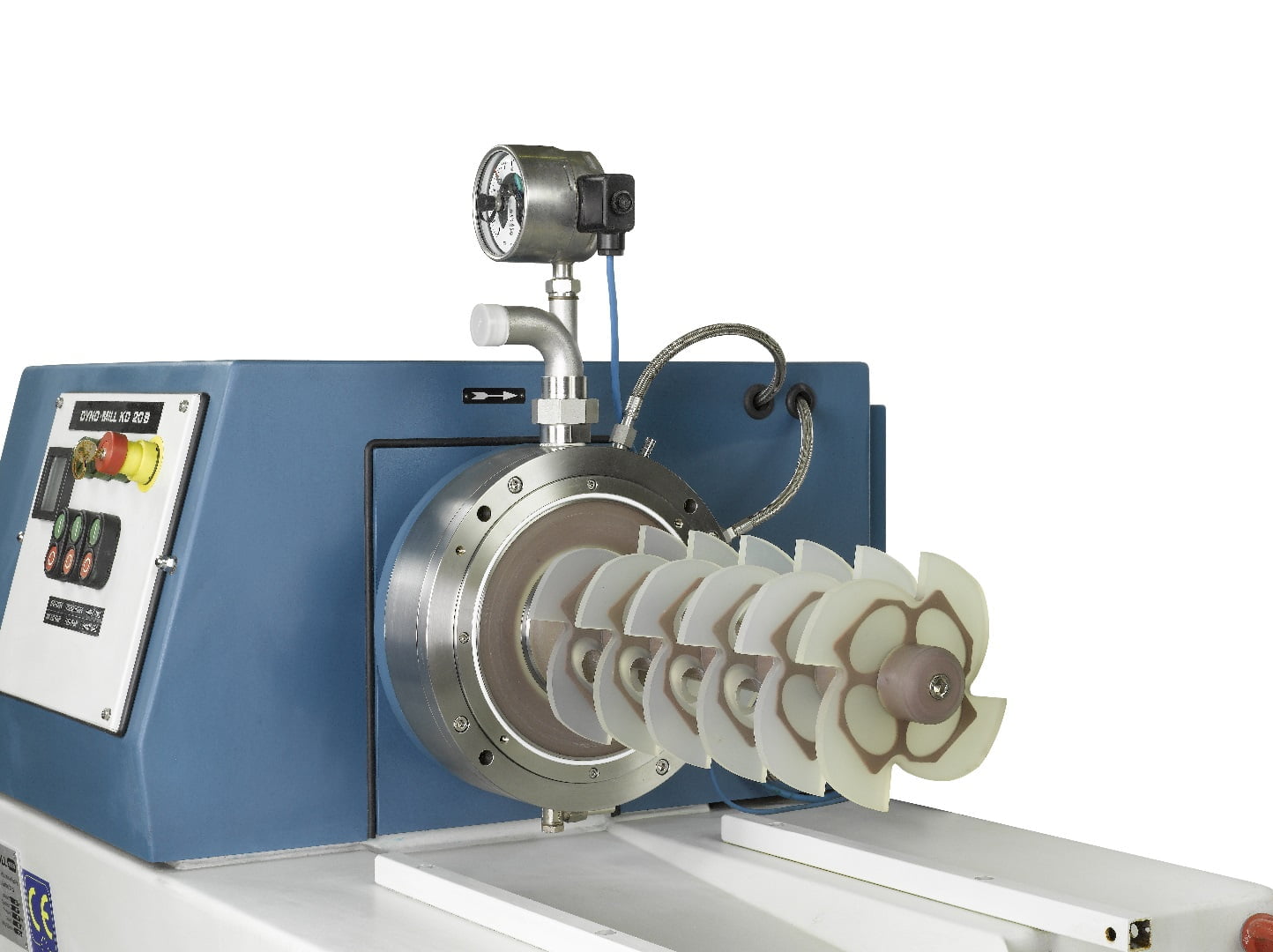

The DYNO -MILL KD disc mills are available with grinding chamber volumes from 0.15 to 600 liters and are suitable for virtually all types of grinding media materials. Functionality In the horizontal grinding chamber, the specially shaped DYNO agitator discs are arranged symmetrically on the agitator shaft. Over 60 years of experience and leading technologies combined in one series: DYNO -MILL Universal Bead Mill (UBM). The new generation of WAB-GROUP agitator bead mill covers the entire range from dispersion to ultra-fine grinding of small product quantities in the laboratory to the production of large quantities.

DYNO®MILL bead mills used for Ecoefficient production methods

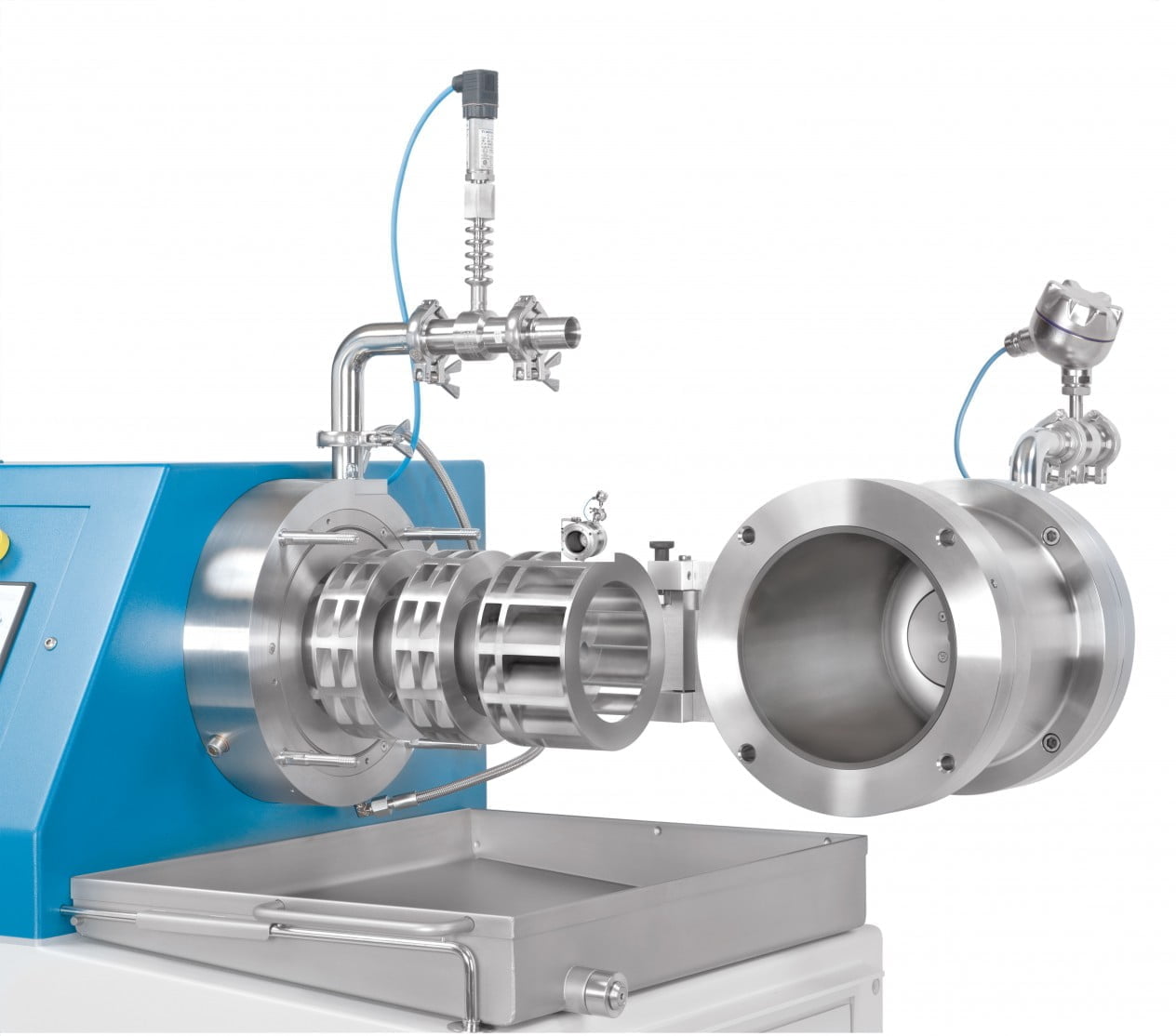

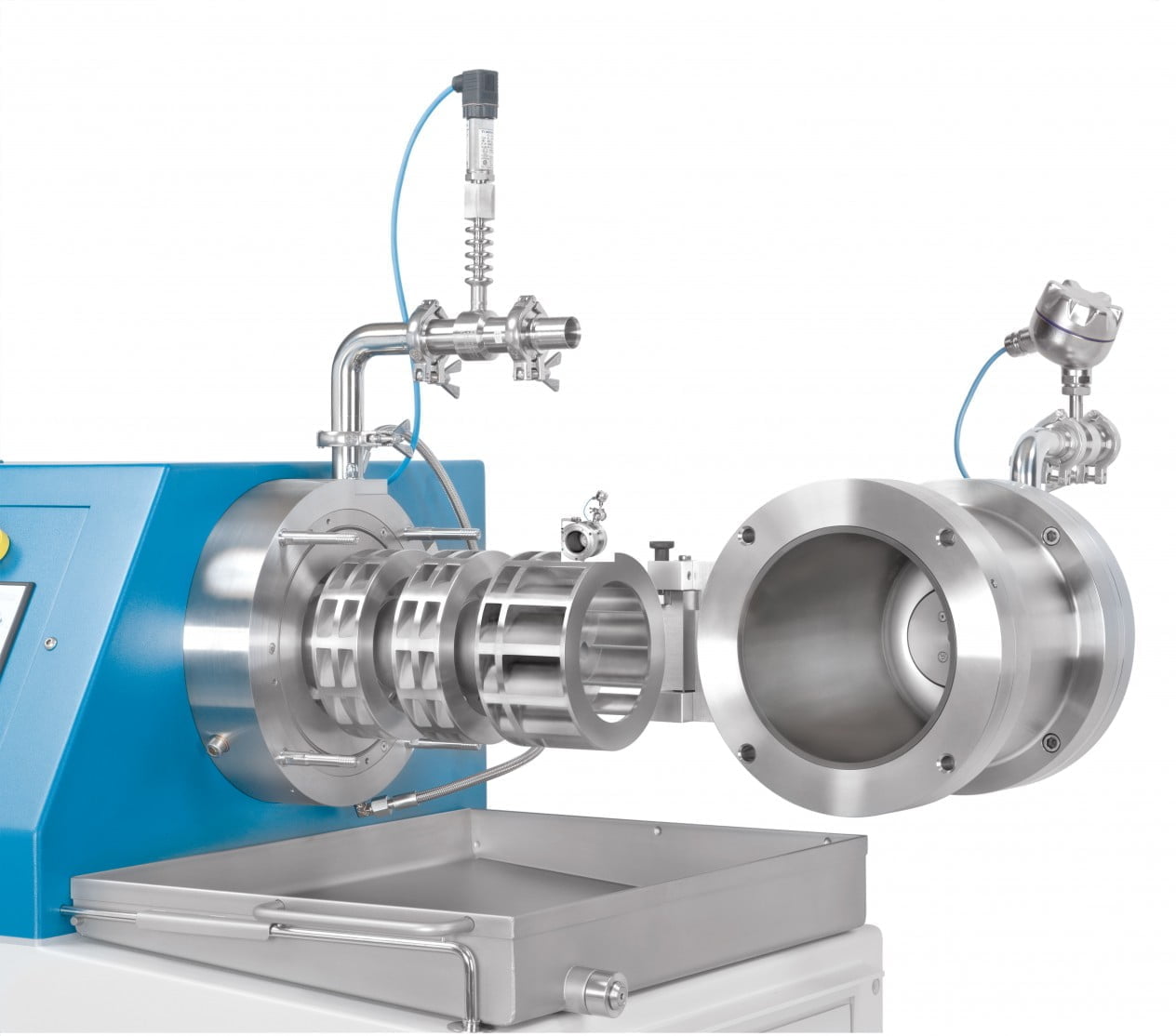

Wet Grinding Mills and Mill Pearls For more than 40 years now, Eskens Process Solutions has been selling, installing and servicing the DYNO®-MILL grinding mills of the Swiss manufacturer Willy A. Bachofen (WAB). With our local stock of spare parts, we ensure you of rapid and efficient service. DYNO ® -MILL UBM is a fully scalable series with a grinding chamber volume of 0.5 litres to 100 litres Consistent design underpins quick and reliable transfer from the lab to the field High wear resistance of the DYNO ® -MILL UBM extends the maintenance intervals, thereby reducing maintenance costs The unique agitator bead mill - the DYNO®-MILL MULTI LAB- is used for the continuous dispersion and wet fine grinding of pumpable products with low to high viscosity in the micron to nano range. DYNO®-MILL MULTI LAB- with 0.6 litre grinding container, WAB VIEW control system 2/8 The DYNO®-MILL UBM bead mills can de-agglomerate and grind with beads from 0.2 to 2.5 mm. They are suitable for grinding processes in recirculation and in passage mode. These agitator bead mills have a grinding chamber of 5 lt. , 20 lt. , 50 lt. and 100 lt.

DYNO®MILL bead mills and grinding beads Eskens Group Process Solutions

Overview Manuals SPECIFICATIONS VIEW LIVE WAB KDL-A Dyno-Mill Agitator Bead Mill This WAB KDL-A Dyno-Mill Bead Mill is used and in excellent condition. Configuration: • Operating Voltage: 3 X 415 V, 50 Hz • Nominal Capacity: 1.85 kW • Nominal Current: 3.55 A • View Photos of Included Accessories Here and Here Open the catalog to page 1 WAB - your expert for wet milling and ultra fine dispersion For many decades WAB has been the undisputed specialist in dispersion and milling technology with its world renowned DYNO®-MILL. The laboratory of the WAB group is fully equipped with different types of DYNO®-MILL bead mills and can also be used for the safe processing of dangerous or unhealthy products. The grinding results obtained are immediately measured in the analysis lab on one of the Malvern Mastersizer 3000 devices that they have available. Mode of operation: Discontinuous operation Two grinding vessels with a volume of 0.15 l and 0.3 l have been specially developed for processing low-viscosity suspensions in batch sizes of 85 ml and 170 ml respectively in discontinuous operation. After grinding, the material to be ground must be separated from the grinding media by washing.

DynoMill KDL Bead mill Gemini BV

The DYNO ®-MILL KD disc mills are available with grinding chamber volumes from 0.15 to 600 litres and are suitable for practically all types of grinding media. The production mills can be operated with grinding bead diameters from 0.5 to 2.5 mm. The bead mill Dyno-Mill type KDL is extremely suitable for the fine grinding of materials for different purposes. This is mapossible by equipping the bead mill for continuous or batch operation and by equipping the bead mill with grinding containers of different sizes. Furthermore, this device is used in the paint and ink industry, chemical.

This dyno mill consists of a horizontal grinding container that is used for dispersion and the finest wet grinding. This process is carried out in a completely enclosed system. Dyno mill working principle is suitable for mixing and grinding materials in two types: dry grinding and wet grinding. Product inlet DYNO ® agitator discs in a wide range of materials Cooled grinding container with easily interchangeable grinding cylinder in hardened or stainless steel, hard chrome plated stainless steel, polyurethane, ceramic 4a Dynamic gap separator 4b Screen separator 5 Product outlet DYNO®-MILL KD 190 A Agitator discs

DynoMill KDL Bead mill Gemini BV

What is the difference between dyno mill and static bead mill? The internal structure of the bead mill Effective grinding linear speed V8mS= (3.14)*D (rotor diameter)*R (equipment speed) The first generation disc rotor of bead mill for wet milling Features The uniqueness of the DYNO -MILL RESEARCH LAB lies in its design: The complete grinding section can be separated from the drive by loosening only three screws. Subsequently, the dismantled grinding section can be disassembled particularly easily in just a few steps. This means that cleaning work can be carried out quickly and conveniently.