Rigger Hand Signals: 7 Most Common Communicating at construction sites can be a day-to-day struggle, especially if the noise is so loud that you can't hear the sound of your own voice. When working around crane rigging, communication can mean the difference between a normal workday and a fatal accident. If you ever watch our Sims Crane Minute videos, Bob always reminds us of the importance of good communication for a safe, smooth crane and rigging operation..

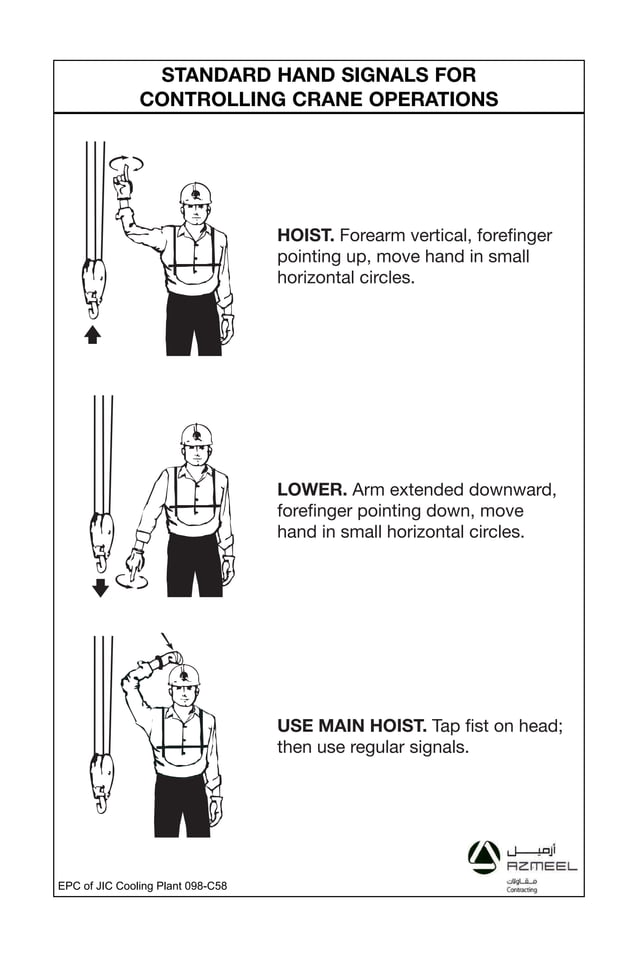

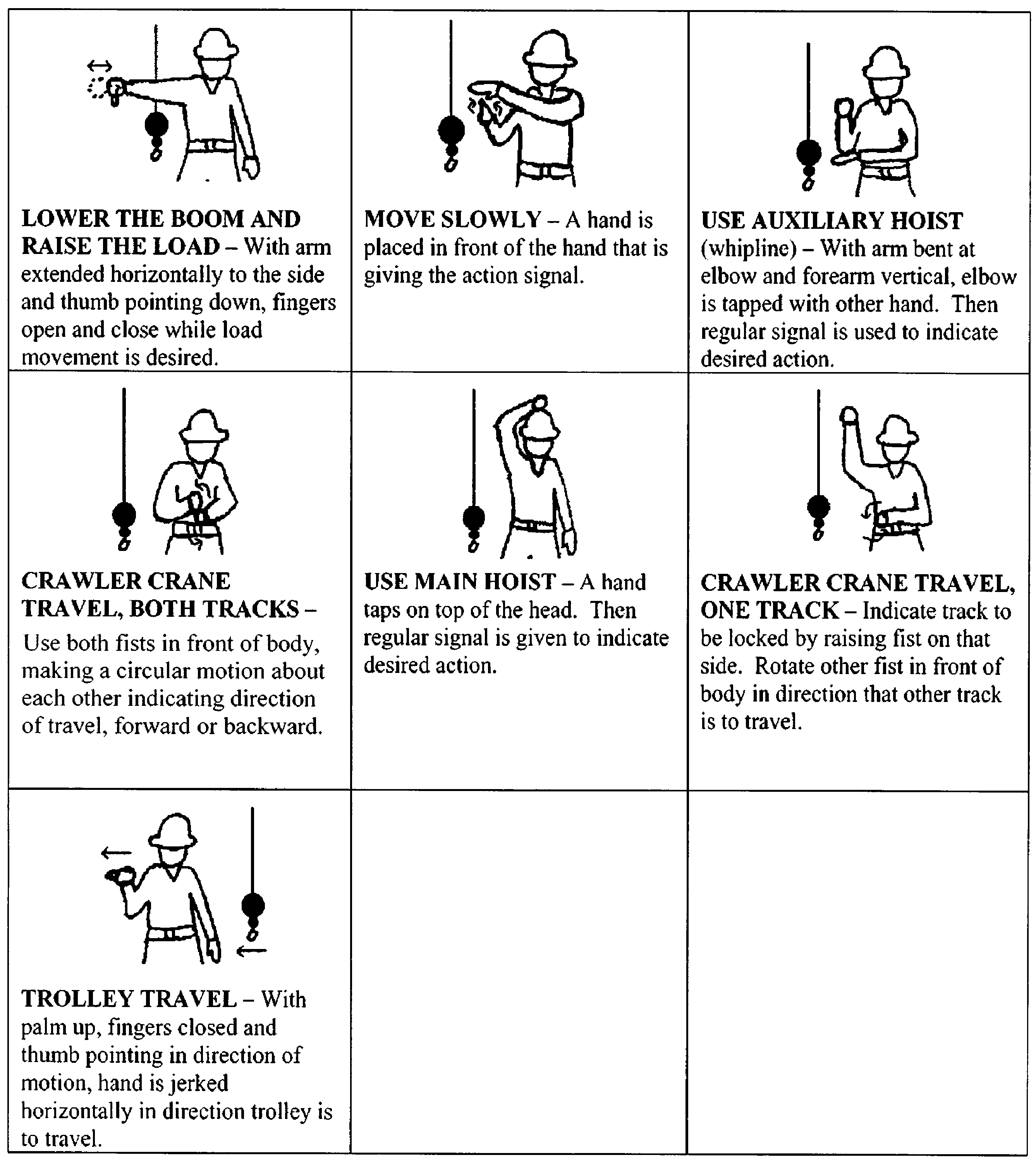

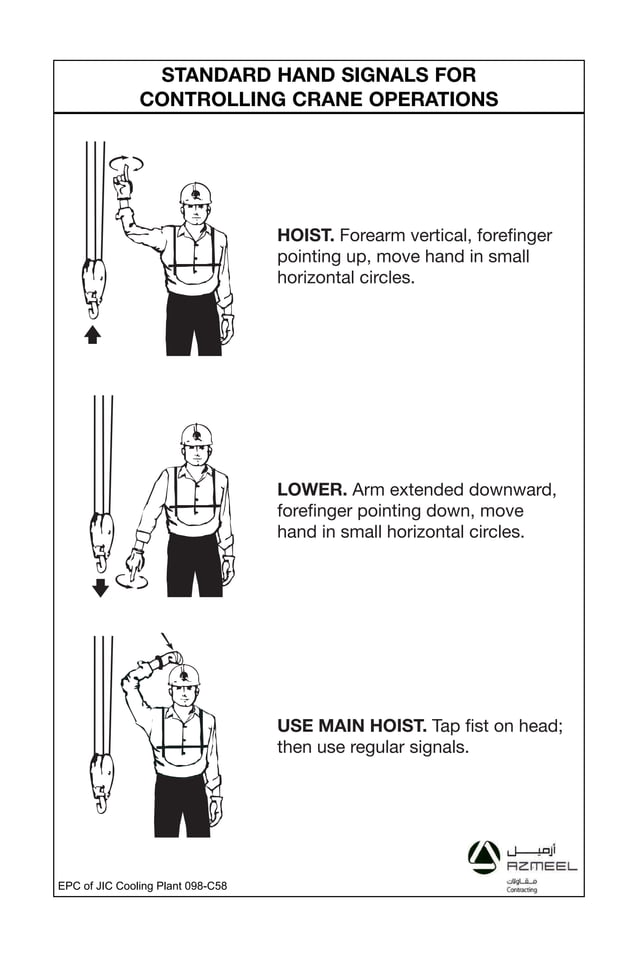

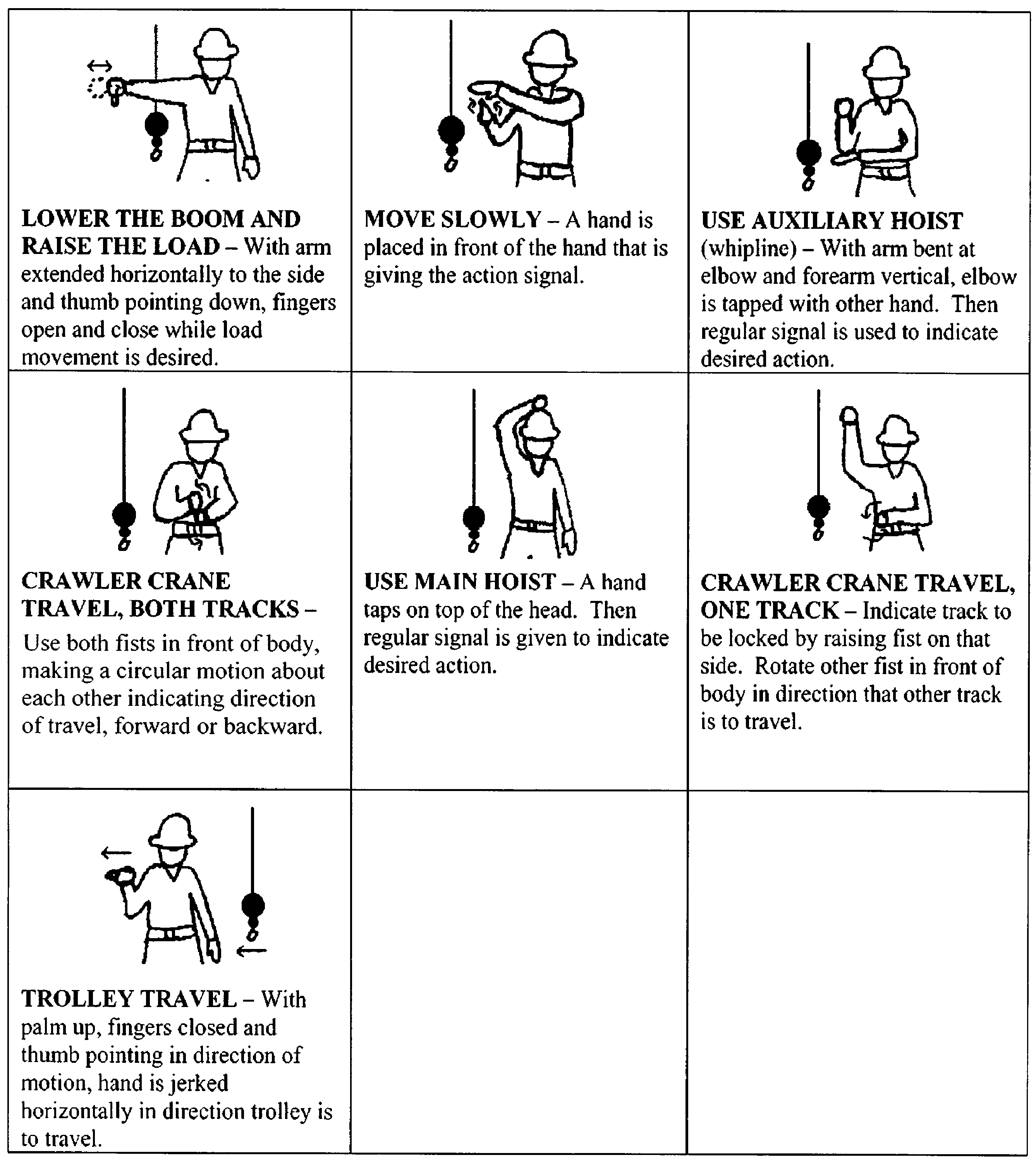

Standard hand signals for controlling crane operations Rigging

Rigging Hand Signals 1. 2. Han d Signals TO "STOP". both your hands are free, extend both arms horizontally with your fingers outstretched (Figure 3). If only one hand is free, you signal "STOP" by facing the palm of your hand toward the operator with your fingers outstretched and waving your hand from side to side (Figure 3). Figure 3 Stop. The crane hand signal person is also responsible for preventing injury and accidents to the best of their ability, this is done by following strict procedure during crane operation, for instance standing in clear view of the crane operator, ensuring the operating area is clear of people or hazardous objects and performing one signal at a time to. Because this role is so important, OSHA requires safety training. Our Rigger Signalman Training meets this requirement. This course covers a wide range of topics including: An introduction to rigging and hand signals. Estimating weights and chapters on sling angles. Different types of rigging gear and hand signals. In this video, we'll provide a brief, yet in-depth explanation on the variety of crane hand signals. Learn more about our signalperson courses here: https://.

Forklift Hand Signals Chart

Hand signals provide a simple solution for the communication issues faced by crane operators. Although radios can be used to relay messages across the site, there are some situations when an operator will need extra assistance. Construction sites are loud. Get your signals straight. Appoint one member of the crew to act as a signal person and instruct the crane operator not to accept signals from anyone else. The signal person must not order a move until getting an " all ready" from each crew member. Each worker must be in the clear before giving an " all ready" to the signal person. Description. Accurate has developed a comprehensive Qualified Rigger and Hand Signal Course in accordance with OSHA 1926 Subpart CC Cranes and Derricks in Construction. Students will learn about General Worksite Safety Rules, Safety Devices, Hazards, Statistics, Inspections, Ground Conditions, Overhead Power Lines, Swing Radius, Operations. Modern day rigging hand signals evolved through necessity. What Are The Advantages? Hand signals require no fancy or expensive communication equipment. Because they are visual they are virtually unmistakable. Because they are universal, there exists no language barrier. Does OSHA Have Required Hand Signals?

OSHA Crane Hand Signal Chart Safety Stickers

What's in the Rigging & Signaling Training Course? Our Intro to Rigging and Signaling training course is regulation aligned, and our online version fulfills classroom training requirements. Each class contains sections on general definitions, site setup, rigging equipment, rigging principles, crane operations, and hand signals. Worker's Safety Handbook for Rigger and Signalman Contents Preface 3 Proper Attire for Rigger and Signalman 4 Roles and Responsibilities of a Rigger 5 Good and Bad Rigging Practices 12 Inspection of Hooks and Shackles 26 Types of Wear and Tear for Wire Ropes 28 Roles and Responsibilities of a Signalman 31 Recommended Crane Hand Signals 33 Good Communication Practices 36 Year of issue: 2011 2.

RIGGER/ SIGNALPERSON 101 COURSE. Course Description: Rigger/Signalperson 101 is a 3-4 hr course designed by Crane U, Inc. to achieve the qualified status required by OSHA. Students will be tested by written exams, hand signal evaluation, and then receive a 2-year qualification wallet card at the completion of the course. June 25 To become a certified rigger and signalperson, an individual must complete an accredited training program where they learn the roles and responsibilities of the position, the proper knowledge of hand signals and voice-activated and audible signals, crane operations and fundamentals of rigging, load handling, and other environmental factors.

Hoisting & Rigging Part III Operator and Crew Member Safety

29 CFR 1926.1422 - Signals - hand signal chart; Rigging Safety Training Course Content. Introduction/General; Site set-up; Determining load weights, sling angles, and stresses; Center of gravity, basic hitches, and sling types; Lifting hardware, below-the-hook-devices, verbal communication, and hand signals; Conclusion This course is ideal for workers who need an introduction to rigging and/or who do not need to rig complex loads. Quiz questions along the way prepare the trainee for the final written examination. The online course and written exam meet the OSHA requirements for riggers and signalers.