The Kaplan turbine was an evolution of the Francis turbine. Its invention allowed efficient power production in low- head applications which was not possible with Francis turbines. The head ranges from 10 to 70 metres (33 to 230 ft) and the output ranges from 5 to 200 MW. Runner diameters are between 2 and 11 metres (6 ft 7 in and 36 ft 1 in). 7.3.1.2.2 Kaplan turbine. Kaplan turbine is a complete reaction turbine that works based on the lift force generated on the impeller blades due to its aerofoil shape [29]. The working process of the Kaplan turbine is similar to the propeller-type turbine along with adjustable runner blades so that it can work smoothly at vortices and shocks.

What is Kaplan Turbine? Diagram and Working Principles Linquip

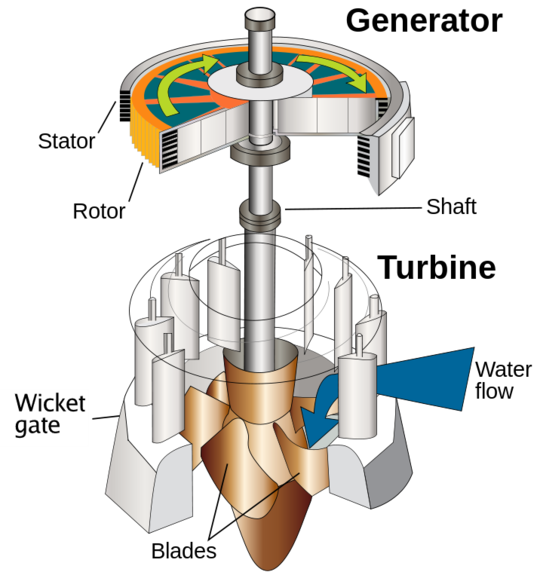

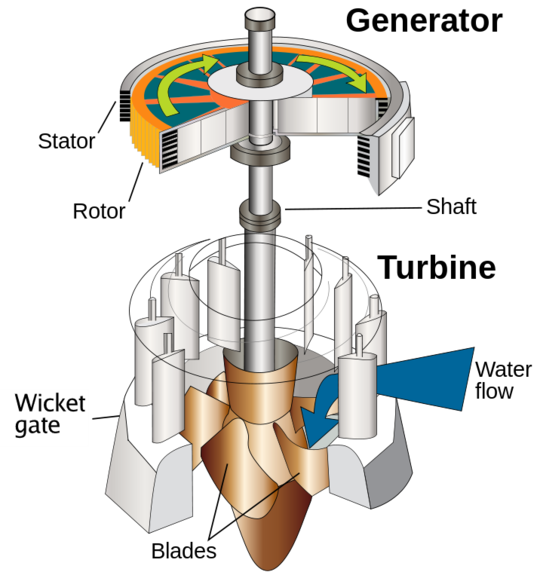

A Kaplan turbine is a type of propeller hydro turbine (specifically a reaction turbine) used in hydroelectric plants.Water flows both in and out of Kaplan turbines along its rotational axis ().What makes Kaplan turbines special is the blades can change their angle on demand to maintain maximum efficiency for different flow rates of water. Water flowing through a Kaplan turbine loses pressure. The vertical configuration of the Kaplan turbine allows for larger runner diameters (above 10 m) and increased unit power, as compared to Bulb Turbines. Our Kaplan turbines also keep the environment in mind. Engineered with a "fish-friendly" structure, to improve the survival rate of migrating species, and water-lubricated bearings and water. A widely used turbine type is the Kaplan Turbine, looking very much like a giant propeller. Its efficiency is very high, it can "capture" over 90% of the kinetic energy of the outlet stream. Today, however, another turbine type is taking over - namely, the Francis Turbine (Fig. 5.11). It was invented 170 years ago by a Massachusetts. Kaplan S-turbine 0 0.1 1 10 100 Output [MW] 50 10 25 5 0 Head [m] CFD illustration: Pressure and velocity distribution in a bulb tubine. 6 Advantages of the bulb design Higher full-load efficiency and higher flow capacities of bulb and pit turbines can offer many advantages over vertical

What is Kaplan Turbine? Diagram and Working Principles Linquip

Although the power output increases with the inlet velocity the efficiency of the runner reaches a maximum of 93.01% with an inlet velocity of 7.64 m.s-1 and then starts to decrease. The original theoretical design in CFD shows a maximum efficiency of about 51-52% (exactly 50.98%), somewhere between 7.64 and 8 m.s-1. The Kaplan turbine is a specialized water turbine designed to generate electricity from flowing water, especially in low-head, high-flow environments. Introduced in 1913 by its namesake, Viktor Kaplan, this turbine has since carved a niche for itself in the world of renewable energy [1]. At its core, the Kaplan turbine working principle. This article presents a comprehensive theoretical and CFD study of a Kaplan turbine, a type of hydraulic turbine that can adjust its blade and runner angles to achieve optimal performance. The authors propose a novel modelling and optimisation method that considers the effects of dimensionless fracture conductivity, a key parameter in the design of hydraulic turbines. The article also provides. One of the most important milestones in the history of hydropower is the invention of the Kaplan turbine. It is a machine stemming from the Francis turbine, which Viktor Kaplan was originally trying to improve. However, it gradually developed into the creation of a completely new solution of an impeller with an axial flow rate and adjustable blades. The first patent relating to the new.

Kaplan spiraltypekaplanturbine Hydrohrom s.r.o.

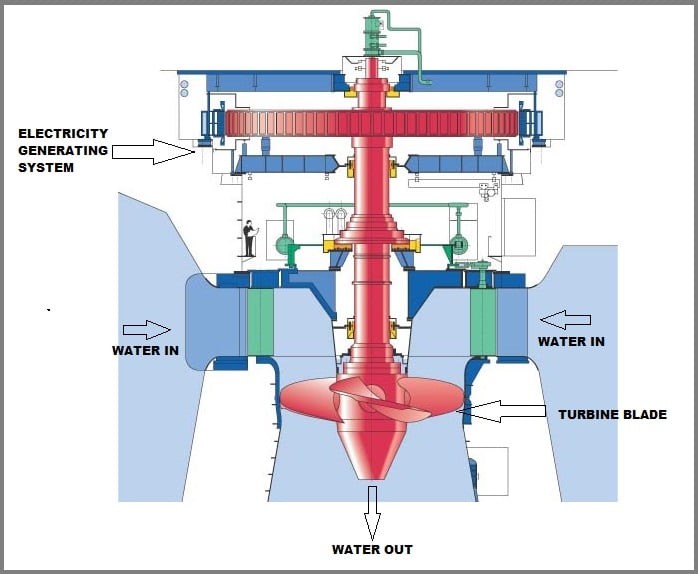

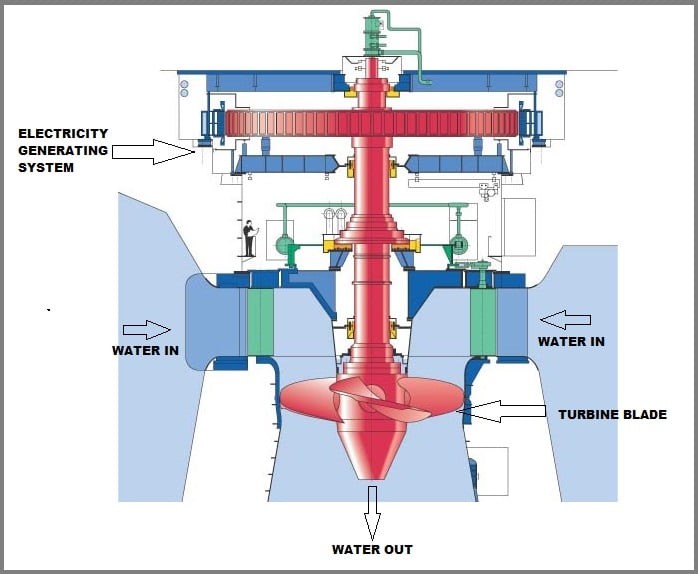

Main Components of Kaplan Turbine. The main parts of Kaplan Turbine are, 1. Scroll Casing. It is a spiral type of casing that has decreasing cross section area. The water from the penstocks enters the scroll casing and then moves to the guide vanes where the water turns through 90° and flows axially through the runner. The commonest orientation currently being installed in the UK (at least by Renewables First) is vertical axis. Vertical-axis Kaplan's have the advantage of requiring the smallest footprint or land-take. A typical layout is shown in Figure 4. The Kaplan turbine is built into the concrete structure, with the inlet volute (basically a snail.

A reaction turbine is one sort of turbine that generates torque by reacting to the weight or pressure of a fluid. The operation of reaction turbines can be described by Newton's third law of motion (i.e. action and reaction are balanced and reverse). The Kaplan turbine is a full reaction turbine that operates by generating lift on the. Kaplan S Turbine; Our Kaplan turbines are equipped with 3 to 6 blades depending on the type and head and have efficiencies of up to 93%. If possible, a direct coupling of the generator and the Kaplan turbine is preferable. Otherwise, power transmission can be realized by using flat belts or gearboxes, depending on the performance class and.

Kaplan turbine Energy Education

The Kaplan turbine is a hydraulic turbine that uses small gradients, up to a few tens of meters, but with a massive flow of water rates, from 200/300 m³ / s. Kaplan turbines are widely used throughout the world in hydropower plants for electrical power production. Constructively, this hydraulic turbine is a propeller, where the blades can be. Kaplan turbine works on the principle of the axial flow reaction. In an axial flow turbine, the fluid moves by the impeller in a direction parallel to the impeller's axis of rotation. A Kaplan turbine works in the following way: First of all, the water introduces into the volute/scroll casing from the penstock.