Best Professional Global Provider Nonwoven and Woven Materials. Contact Us Here. Our Team Makes It Easy For You To Place A Custom Order. Contact Us Here. Needle-punched nonwovens are commonly used for applications offering cushioning and reinforcement against subgrade surface irregularities. These surface irregularities can impact concentrated forces perpendicular to the plane of the geotextile, leading to its puncture failure.

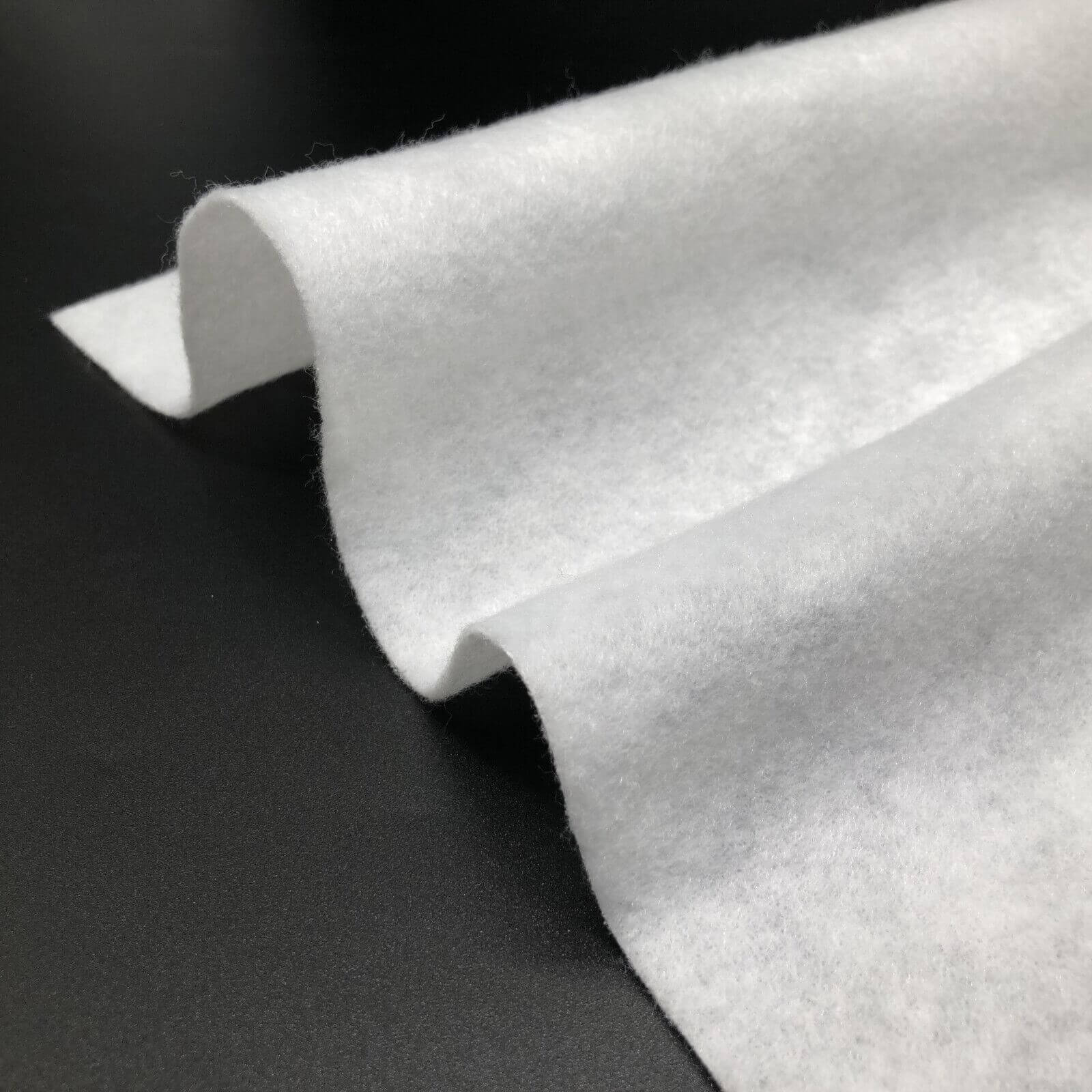

Best Sell NeedlePunch Nonwoven Fabric For Shoes Lining Needle Punch

Simple entanglement of fibers is also possible through mechanical puncture with steel or water needles.1-3 Owing to their excellent properties, such as high porosity and low cost, nonwovens and their composites with other materials can be used for a range of applications, including geotextiles for soil reinforcement, medical applications, filtra. Needle punching is one of the methods used for making a nonwoven felt. This involves taking loose fibers and "needling" them together using a needle loom full of barbed needles to force the fiber to push through and entangle itself. It is also one of the types of nonwoven that Bouckaert Industrial Textiles specializes in producing. rolls Punching speed: 1,000 - 2,200 rpm ProWin™: Web profiling for needlepunch lines Advantages offered by neXline needlepunch Cost efficient, flexible, and reliable turnkey needlepunch lines Customized carding solutions with the aXcess and eXcelle ranges Fiber saving, homogenous fabric characteristics, thanks to ProWin™ system the industry. Needlepunched nonwovens are produced by mechanically interlocking the fibers of a carded, airlaid or spunbonded web using a needle-loom. Early needlelooms operated at relatively low speeds. of up to 100 strokes per minute. Jute, sisal and animal hair were the major fiber materials used in.

NEEDLE PUNCHED FELT VUTEKS TEXTILE NONWOVEN

The needling process also known as "needle punching," was developed as a new generation felt process as a method of forming textiles or fabrics directly joining fibers and bypassing the need for yarn. The term "nonwoven" was created as a result of this manufacturing technique producing fabrics without a weaving or knitting process. Spunbonded needle-punched nonwoven geotextiles are an important part of the nonwoven geotextile family. In these geotextiles, filaments are mechanically entangled to form a complex three-dimensional structure, which provides the geotextile a bulky nature. Lydall's total annual needlepunch nonwoven related sales will be approximately $400 million when including the acquisitions and are reported through its Thermal/Acoustical Fibers and Technical Nonwovens segments. Lydall acknowledged Texel's strength in several adjacent markets, such as geosynthetics, liquid filtration and automotive, when. As shown in Table 3, with a high interlocking of fiber, needle punch density of nonwoven fabrics is high in 550 g/m 2 to 90 leading to decrease in the tearing strength.-Tensile properties: A force.

Needle Punched Non Woven Fabric Needle Felt Texture Supplies

Out of different technical textiles, needle-punched nonwoven is one of the promising technical textiles which has wide ranges of applications. This present chapter deals with jute and synthetic fibre-based needle-punched nonwoven. The design and manufacturing of such nonwoven and proper characterization of the developed fabrics based on the end use has been covered. Jute and jute-based. Needlepunch Nonwovens for: Laminating & Coating • Filtration • Health Care • Home Products • Molding New England Nonwovens (formally the Deitsch Plastic non-woven division) is a leading manufacturer of engineered needlepunch nonwoven fabrics for a variety of markets and applications.

Needle punch nonwoven are made by entangling fibers with each other using barbed needles. This type of fabric is strong and durable, making it ideal for a wide range of applications. the fabric are made from a variety of materials, including polyester, nylon, and cotton. Improved Washability Needle-punched non-woven fabrics are created by carding loose fibers into a felt-like batting that is then punched together using barbed felting needles.

Needle Punched Non woven Fabric,Needle Punch Nonwoven

Needle punched nonwoven fabrics were produced using jute fiber ratio of 5%, 10%, 15%, 20% with 25% kapok, 25% coarse cotton and remaining fine cotton fibers. Oil retention capacities of needle punched nonwoven fabrics were found to be in the range of 7.75 g/g to 16.60 g/g under various process conditions. nonwovens - also called needle felts - are still the most important technology for transforming. fibers into a fabric. The estimated global share of needlepunched nonwovens is 30 percent. Needlepunching is a very traditional method of forming nonwovens and is especially suitable in. terms of flexibility, quality and product diversity.