Though programmable logic controllers (PLCs) have become dominant across industry, there are still many applications using remote terminal units (RTUs). Deciding which is right. Programmable logic controller (PLC) Remote terminal unit (RTU) and Smart instrument 1. SCADA system A SCADA (or supervisory control and data acquisition) system means a system consisting of a number of remote terminal units (or RTUs) collecting field data connected back to a master station via a communications system.

PLC, Telemetry and SCADA Technologies (Virtual) Peganix

Telemetry is defined as the sensing and measuring of information at one location and then transmitting that information to a central or host location (PLC / DCS). There, it can be remotely monitored and used to control a process at the remote site. The basic concept of remote monitoring with telemetry has been in existence for a long time. Remote terminal unit. A remote terminal unit ( RTU) is a microprocessor -controlled electronic device that interfaces objects in the physical world to a distributed control system or SCADA (supervisory control and data acquisition) system by transmitting telemetry data to a master system, and by using messages from the master supervisory system. Power-line communication (also known as power-line carrier ), abbreviated as PLC, carries data on a conductor that is also used simultaneously for AC electric power transmission or electric power distribution to consumers. In the past, powerlines were solely used for transmitting electricity. They are similar to a programmable logic circuit (PLC) but have more in-depth functionality. These intelligent controllers assert supervisory control over other devices in order to automate industrial processes. This allows for the transfer of data (usually wireless) across a large geographic area.

SCADA and Telemetry in Nashville, TN Communications Group Inc.

RTU/PLC - Remote Telemetry Unit more… An RTU or Remote Telemetry Unit describes a system or package at the remote sites that monitors and controls the remote sites. An RTU sytems includes the controller, RTU, or PLC; Power Supply, and Data Communications Subsystems. The complete package is typically referred to as an RTU package. A PLC requires specific software and specific skills and knowledge of ladder logic, structured text, function block, etc. A RTU can sometimes be programmed through a simple web interface. In other instances, the RTU comes with setup software that can help you to configure input streams to output streams as well as communications. POWERFUL, SECURE AND RELIABLE. Kingfisher RTUs offer a powerful and reliable technology solution that simplifies automation tasks and provides a secure connection to your assets, all while reducing the risk of failure. This enables critical infrastructure industries to control and monitor data from geographically dispersed assets in real-time. The central station relies on the sensors to gather and report telemetry data. These sensors can be Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs). The RTU or PLC collects information locally and then passes it on to the central station in real time.

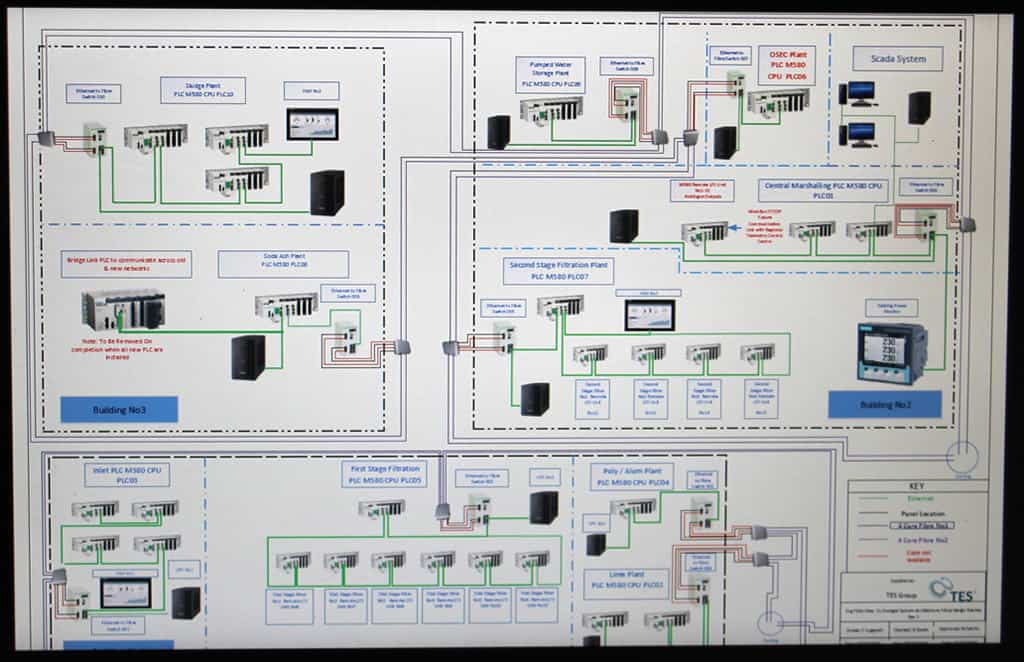

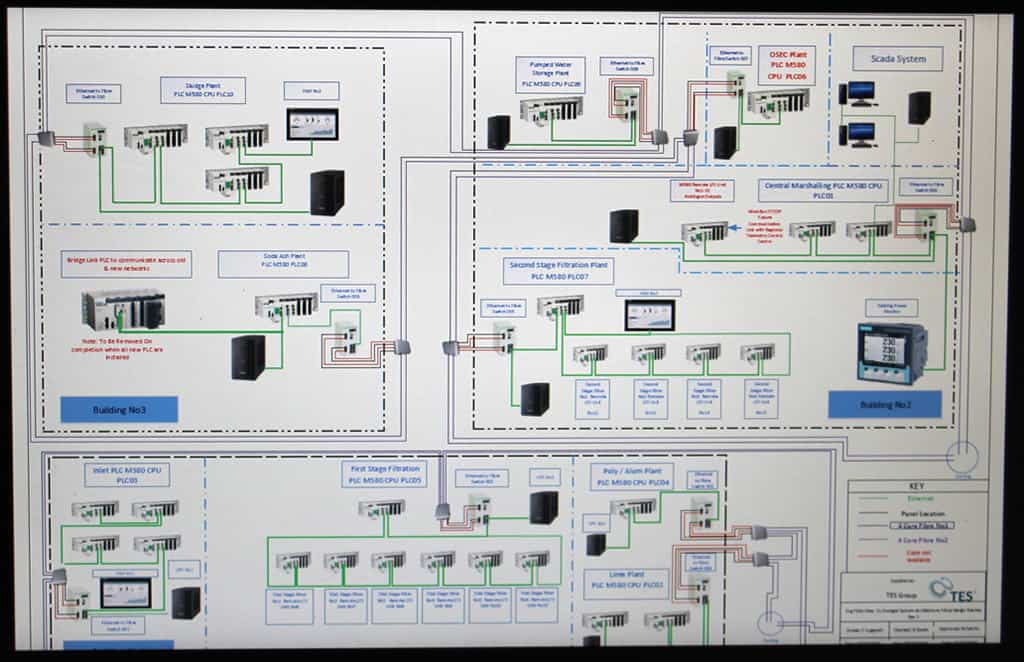

TES Telemetry Outstations providing remote monitoring and control

This PetroKnowledge online PLC, Telemetry & SCADA Technologies training course is 'hands-on' using industry standard PLC's in a simulated environment. Through this approach the delegate will progress from learning the fundamentals of PLC application to writing, debugging and finally designing their own programs. How does a PLC compare to a Remote Telemetry Unit? An RTU, compared to a SCADA PLC, is generally more rugged and has higher monitoring and control capacities than a PLC. This makes SCADA RTUs superior at locations where many items must be monitored and controlled. If you have more locations that require just a few monitor/control nodes, then.

Protocol Converter The system is excellent for industries requiring local and/or remote control or tie-ins to existing control systems. Remote access to TBox can be via PSTN, ISDN, GSM/GPRS/3G, RF, Ethernet LAN, Internet, VPN, Leased or Private Line, Satellite and others. PLC, Telemetry & SCADA Technologies Introduction: This is a highly relevant, industrially based training course that will update the skills and knowledge of Technicians and Engineers alike. This course is 'hands-on' using industry-standard PLC's in a simulated environment.

PLC gateway / communication / Modbus / telemetry RITM Industry

2.1 Telemetry. Telemetry is the initial step in applying SCADA by defining the technique used for measuring the data (voltage, current, speed, etc.) from different locations in the real-time process and transferring it to the IEDs such as remote terminal units (RTUs) or PLCs in another location through a communication circuit. 2.2 Data Acquisition Specifying the PLC connection settings, such as the PLC model, communication protocol, and connection parameters. Configuring security settings, including certificates, encryption, and authentication mechanisms. Defining OPC UA data tags and their corresponding PLC addresses or variables.