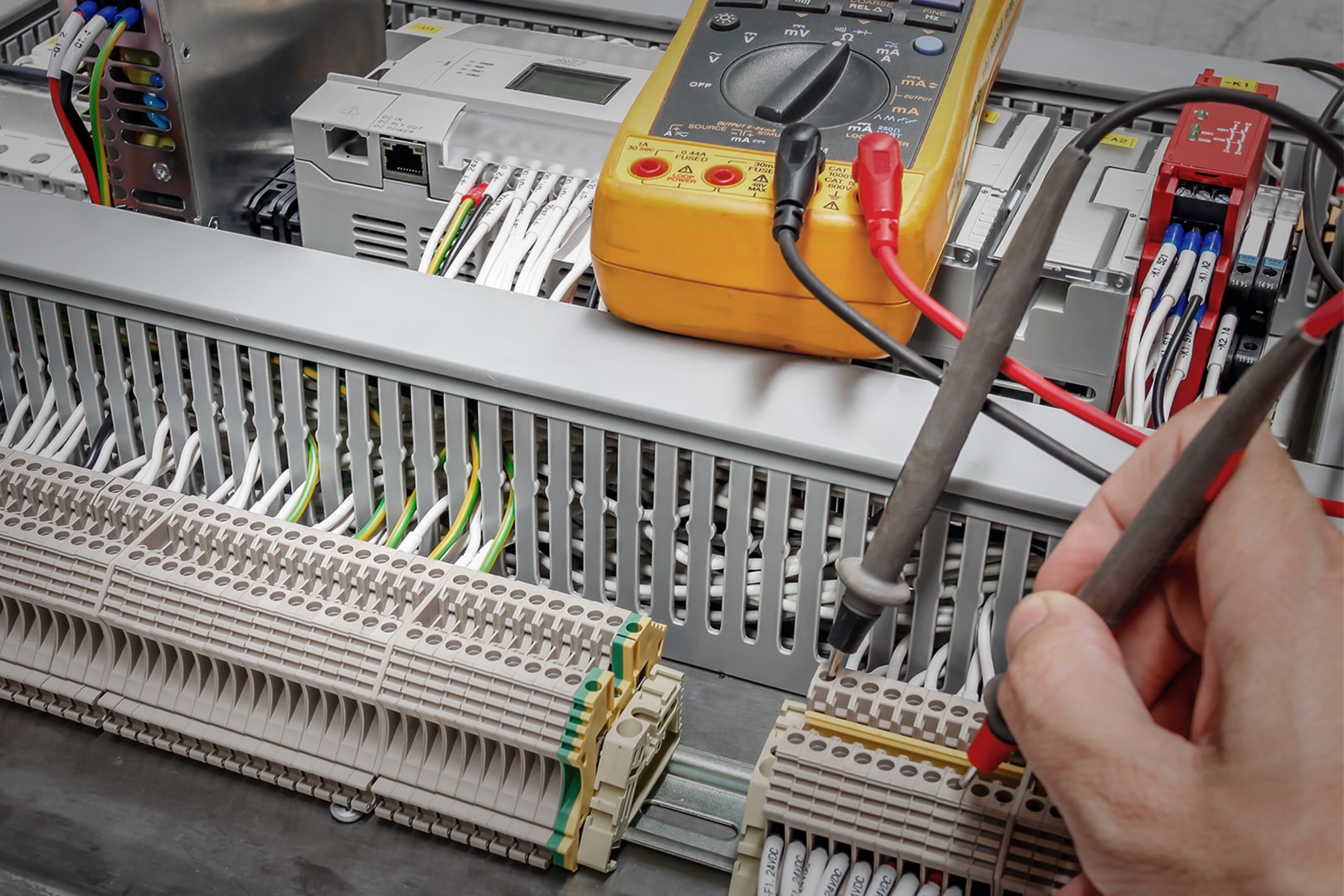

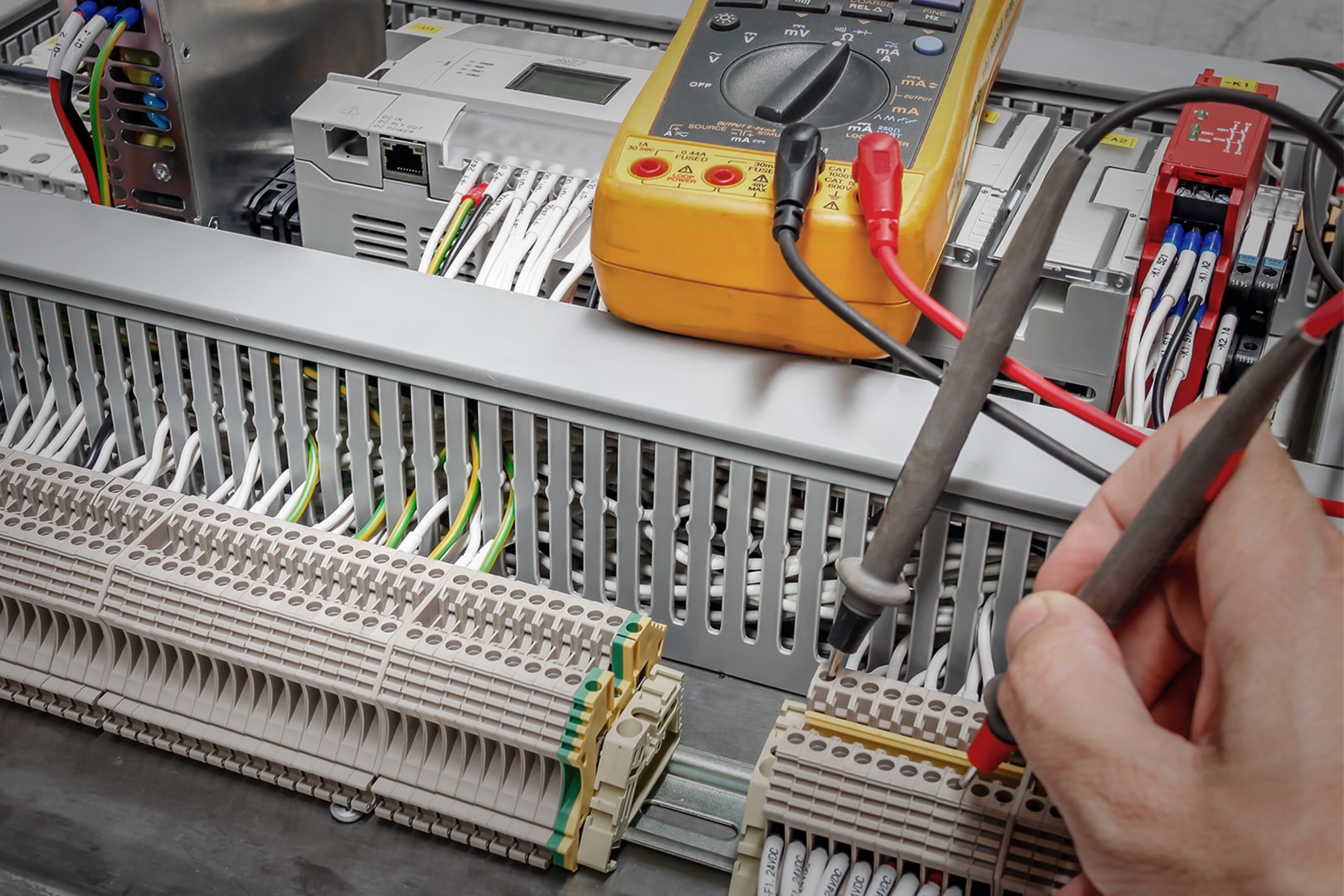

PLC installation - input/output Input/output installation is perhaps the biggest and most critical job when installing a PLC - programmable controller system. To minimize errors and simplify installation, the user should follow predefined guidelines. Electrical wiring diagrams of a PLC panel In an industrial setting a PLC is not simply "plugged into a wall socket". The electrical design for each machine must include at least the following components. Transformers - to step down AC supply voltages to lower levels

How To PLC Wiring In Control Panel The Automization

Reading a PLC Wiring Diagram is one of the must-to-learn skills for every automation and electrical engineer. Despite different standards of these types of drawings, you'll learn using actual industrial drawings and some PLC wiring best practices. 1. Ensuring System Reliability: Proper PLC control panel wiring is critical for ensuring the overall reliability of the system. Any loose connections, improper grounding, or incorrect wiring can lead to voltage fluctuations, signal interference, or even system failure. Wiring in a PLC control panel is a hectic job and requires a good understanding of PLC standards as well as electrical standards. Basically, before PLC was being started to be used in the market, wiring was the only method to provide control of a system. PLC wiring connection is an integral part of any automation system, as it involves the physical connection of various devices to the Programmable Logic Controller (PLC). This comprehensive guide will provide you with in-depth knowledge on how to establish proper wiring connections for PLCs, ensuring the smooth operation of the automation system

PLC Ladder Logic Contacts and coils Instrumentation Tools

Join us here, get awesome perks, and support us, all at once:https://www.youtube.com/c/upmation/joinRead the full blog post at https://upmation.com/plc-w. A PLC panel is simply an electrical control panel consisting of electrical components which use electric power to control a variety of mechanical functions of industrial machinery or equipment. In order for industrial machinery and equipment to accomplish their various process goals, they require user-defined functions and well-organized control. Slide the wires into the slots on the bottom, and using the screws found on top, you secure the wires. Some connectors are like the one shown, and disconnect from the PLC, while others are fixed to the the PLC. This kind of connection is common for Inputs, Outputs and power supplies. Internal Connections More Information This video explains the various terminals of PLC and its wiring fundamentals. It show's how to connect Inputs and Output to the PLC terminals.

automationplcwiring3 The Stiegler Company

C'mon over to https://realpars.com where you can learn PLC programming faster and easier than you ever thought possible!===== Chec. Join us here, get awesome perks, and support us, all at once:https://www.youtube.com/c/upmation/joinWhen you look at an industrial control panel wiring dia.

The wiring of a PLC ( Programmable Logic Controller) is a fundamental part of the installation and commissioning of automated control systems. PLCs are used to control various industrial processes and machines. The wiring connects the PLC to sensors, actuators, and other devices on the factory floor. PLC wiring diagrams are graphical representations of the electrical connections and devices used in a PLC system. They provide a visual guide for technicians and engineers to understand how the different components are connected and how signals flow through the system.

Basic electrical design of a PLC panel (Wiring diagrams) EEP

PLC Digital Signals Wiring Techniques by Editorial Staff Ina process plant, on/off control is done through the PLC or DCS. The below Figure is an overview of one discrete/digital (on/off) circuit, showing the entire process from the power supply through the sensor and on to the PLC. Table of Contents PLC Digital Signals Wiring Techniques a. A wiring diagram gives the necessary information for actually wiring-up a group of control devices or for physically tracing wires when trouble-shooting is necessary. A line diagram gives the necessary informa- tion for easily following the operation of the various devices in the circuit. It is a great aid in trouble-.