Rubber Mold Design: How to Design Perfect Rubber Mold Part Updated: November 11, 2021 Rubber molded products are now an essential part of almost every industry. They are everywhere, from aviation to cars and even in household equipment. The reason for this is not a hard nut to crack. Molding of Rubber and Design of Rubber Molds Learn the fundamentals of molding rubber mechanical goods and designing their rubber molds with no reference to the molding of tires. Review applicable molding methods with emphasis on compression, transfer and injection processes.

THE CUSTOM RUBBER MOLDING Professional Tooling Mold Maker, Rapid

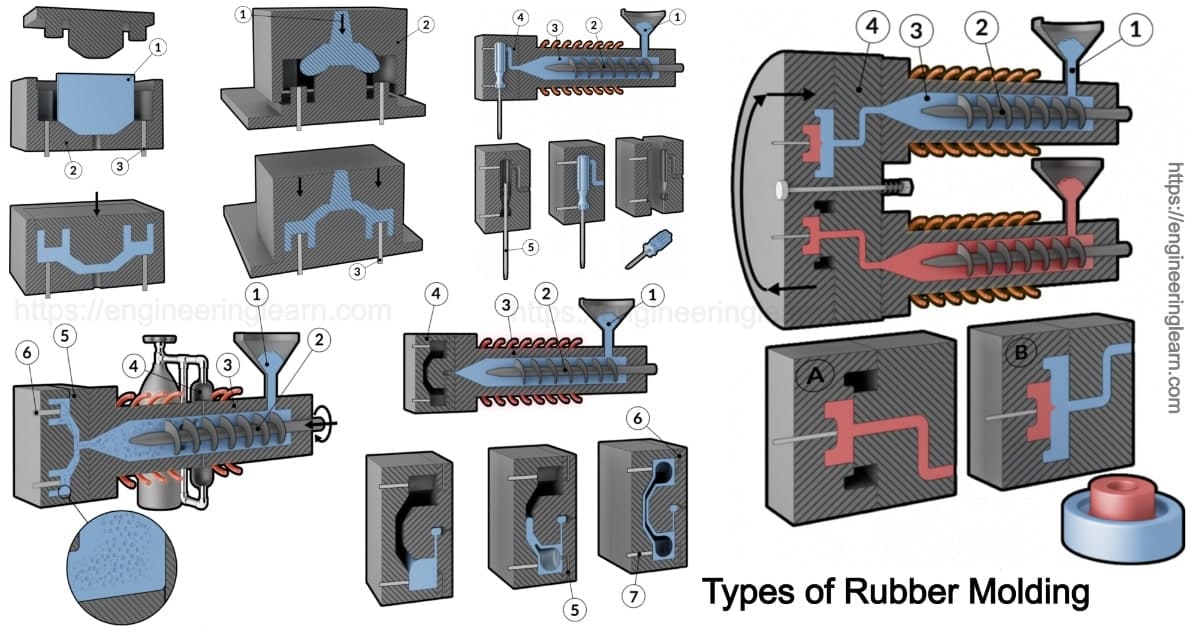

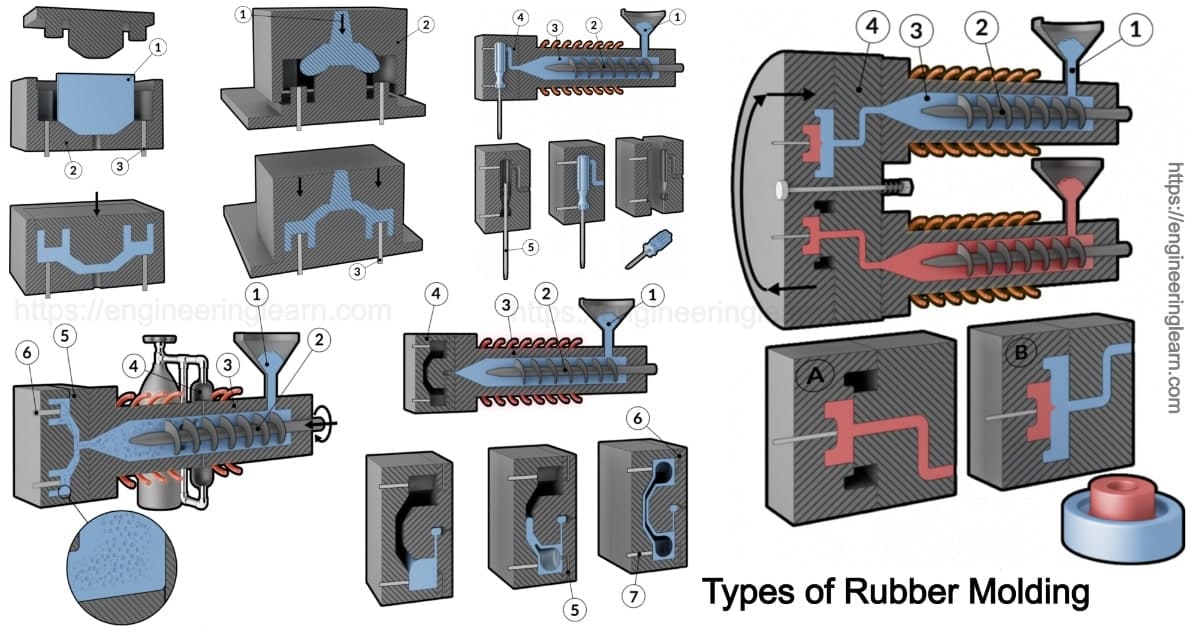

The Engineer's 7-minute Guide to Rubber Molded Parts is just as it sounds, a quick-reference guide to help you determine if exploring a rubber part is right for your application. Designing new products or parts around existing components can be costly and time-consuming. Updated: July 19, 2022 Rubber products are ubiquitous in nearly every industry nowadays. They play a vital role in functions like sealing, abrasiveness, insulation, etc. As a result, they are critical in upholding high industry standards and development in today's fast-paced world. Rubber molding is a manufacturing process that turns uncured rubber and other elastomeric materials into usable parts and products. It involves placing, pressing, or injecting the material into the cavity of a metal mold. Then, pressure and heat are applied, which initiates a chemical reaction—i.e., curing or vulcanization—within the material. This comprehensive design tool details rubber and plastic design issues including a materials overview and prototype mold design considerations. Designing Rubber Components Overview Working Together Engineering Design Cost Effective Custom-Molded Seals Avoiding Rubber Component Design Problems Properties in Balance Selecting an Elastomeric Material

Rubber & Silicone Molding Manufacture Sanhao Custom Rubber

Rubber Molding manufacturing is facilitated by either extruding, pressing or pouring a liquid into a mold. Most rubber products made from vulcanized rubber with sulfur at high temperature during the molding process or after extruding. 07. Polymer Report History of Rubber The story of Charles Goodyear and vulcanization You can not speak about the history of rubber without mentioning Charles Goodyear. His name graces the tires under millions of automobiles and is credited with inventing the process for the modern form of rubber: Vulcanization. At Martin's Rubber, we have a dedicated tooling department that allows us to be agile and responsive to your prototyping needs. We can design an effective mould tool for your specified rubber mould design using high-tech CAD and CAM software. We will adapt your 2D or 3D drawings and liaise closely with you until you are satisfied with the. Rubber transfer molding is an ideal process for molding parts that require multiple cavities, intricate parts that require a closed mold, bonding rubber to metal parts and if the geometry of the part might cause mold cavities to trap air. Processes

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

The purpose of this section is to provide a method for standard- izing drawing designations for specific design requirements of molded rubber products. Information set forth on the pages that follow should be helpful to the design engineer in setting up real- istic specifications for molded rubber products. The Rubber Molding Process. Our rubber molding processes involve heating, forming, and curing rubber compounds inside a mold under pressure. The cavity of the mold is the shape of the finished part and based on the flexibility of the required material, the product design may include complex shapes, compound curves, and undercuts.

Custom Molded Rubber Parts RESPONSIVENESS ~ FROM DESIGN TO DELIVERY™ We are committed to delivering not just quality molded rubber components on time, but also delivering the best customer experience throughout the entire process, for the life of the relationship. Services Custom Rubber Corp. focuses on a core competency of molding rubber parts. Rubber molding is a process that can be used to create parts with a wide variety of shapes, sizes, and designs. A rubber mold is an integral part of the rubber production process because it allows the component, part, configuration, and design of a rubber product to be precisely tuned to match the requirements of an application.

Types of Rubber Molding Engineering Learn

For more information about our Quality policies and initiatives, please contact us today! Reuther Mold started designing and manufacturing molds and rubber tooling for the rubber industry from its beginning in 1950. Call us at 330-923-5266 for a quote. Rubber moulding is a flexible production procedure that uses specialized moulding to shape rubber products into numerous kinds. Rubber moulding supplies numerous advantages, including style versatility, product flexibility, cost-effectiveness, and improved product performance.