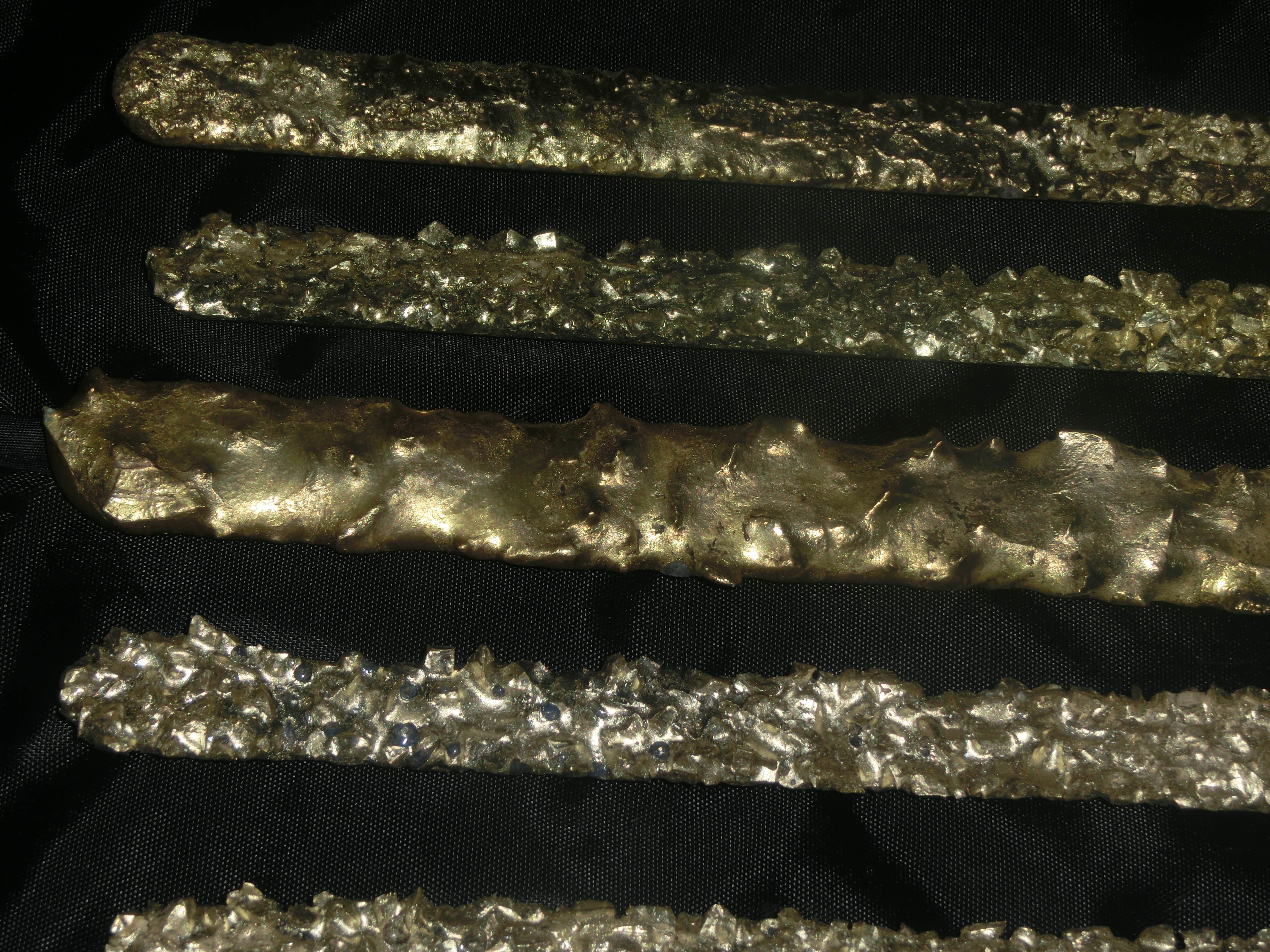

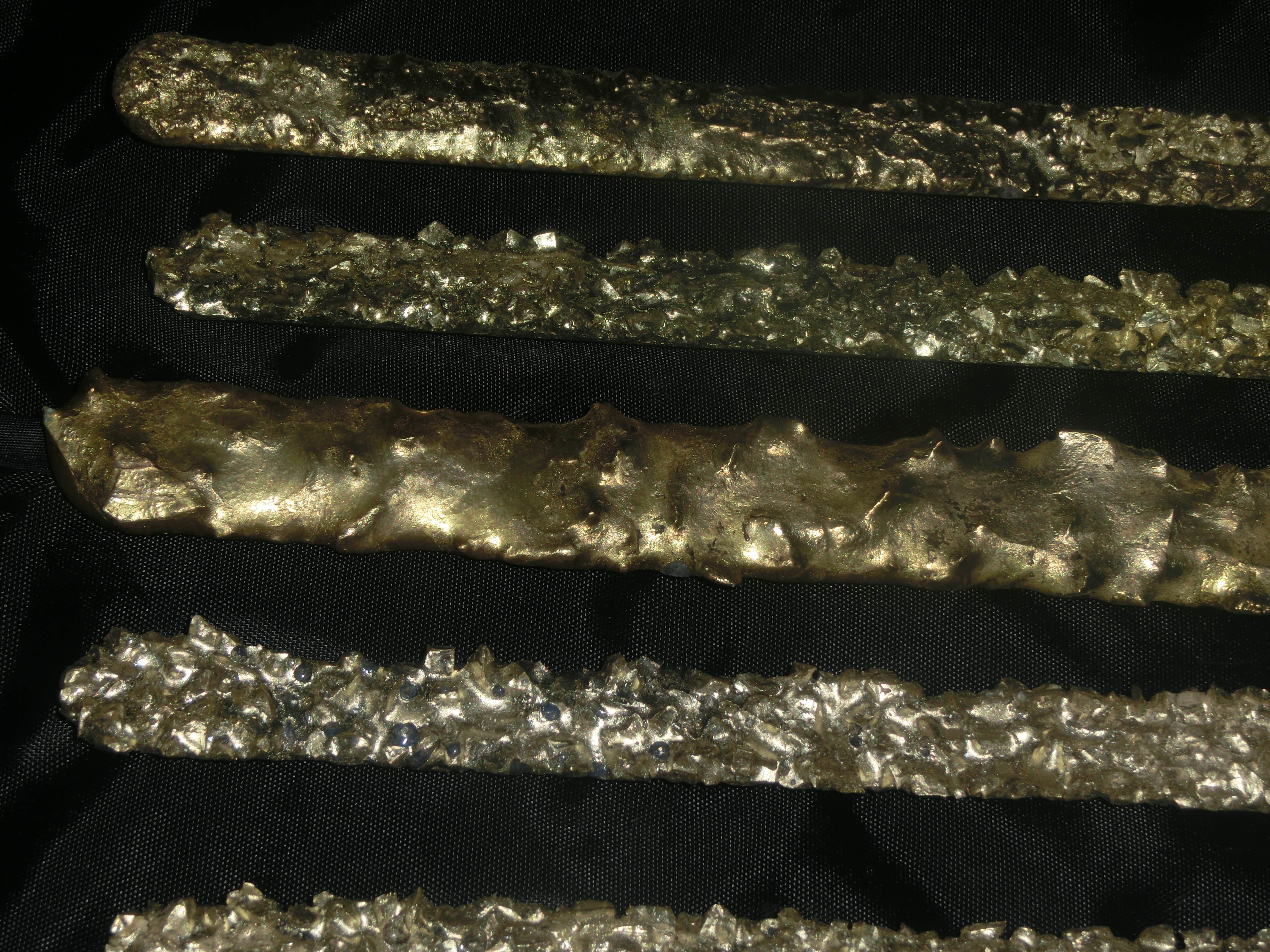

Tungsten carbide composite rods (welding rods) are ideal for protecting high-wear components of equipment in the oil and gas drilling, geothermal, mining, and geological exploration industries, including washover shoes, stabilizers, down-the-hole drill bits, reamers, drill rods & subs, etc. Carbigrit Crushed Tungsten Carbide Grit is Produced in a Process That Yields Blocky Particles & Multiple Sharp Edges and Points. Carbigrit Crushed Tungsten Carbide is Applied by Brazing, Epoxy Bonding, or Various Welding Methods. Rigid Material And Process Controls Yield Consistent Properties Lot-to-Lot And Year-to-Year.

Virgin Tungsten Carbide Composite Rods , High Toughness Carbide Round Bar

These rods are used in a variety of applications which involves downhole milling and cutting, rock drilling, reaming and the farrier industry.Composite rods consist of tungsten carbide particles suspended in a copper based binder for severe impact and wear applications. (936) 825-2532 email us Dynarod provides weld deposits consisting of layers of multi-faceted chips of Tungsten Carbide in a Nickel Silver, Nickel/Chrome/Boron, or Silicon Bronze matrix. Our aggressive Tungsten Carbide chips are cast into rod form with a Zinc-Free, durable Silicon Bronze matrix. Tungsten carbide composite rods will help you achieve peak wear and damage resistance. Visit Lineage shop today for your tungsten carbide rods! Cronimet Specialty Metals CARBIROD™ is a high-quality, tungsten carbide composite rod, formulated and manufactured in the USA. Our CARBIRODS™ are made of premium uncoated carbide grit, branded CARBIGRIT™, available in various formulations of a Nickel Bronze Alloy Matrix. Our rods are to be applied to clean steel surfaces with an Oxy.

Tungsten carbide composite rod

Kennametal's Tungsten Carbide Composite Brazing Rods are manufactured using only premium, clean, KenfaceTM WC-Co particles. The quality of WC-Co particles allows for excellent wetting of the tungsten carbide particles during deposition, thereby virtually eliminating "burnt" carbides and premature breakdown of the deposit. APPLICATIONS SKU: CGSCR5 1/8 X 1/16 UNCOATED CRUSHED TUNGSTEN CARBIDE Create your own composite rod using our composite rod material. Our crushed tungsten carbide is sorted for even particle size distribution in the manufacturing needs of composite rods or thermal processing. $ 21.00 Price Per lb $ 210.00 add to cart Product Application REVIEW Joining and Hardfacing Home - Products - Joining and Hardfacing - Tungsten Carbide Composite Rod Dura-Metal's tungsten carbide composite rods have been used and respected throughout the Oil drilling industry worldwide. SupaCutt is a composite rod used for cutting applications and is manufactured from steel cutting grade tungsten carbide to produce high quality angled fragments. Available in a range of sizes and blended to optimise the packing density when laid. SupaWear Ideal for stabilizers and other gauge protection products

Virgin Tungsten Carbide Composite Rods , High Toughness Carbide Round Bar

Max Carbide manufactures premium quality Tungsten Carbide composite brazing rods in a Nickel Silver, Nickel/Chrome/Boron. Copper tungsten carbide composite brazing rod is also calld YD welding rods, composite rods, which is composed of matrix alloy and tungsten carbide grits. Surface is coated with a special flux and colored to identify the. Carbide composite rods are made up of two main components: tungsten carbide particles and matrix material. The tungsten carbide particles provide the hardness and wear resistance needed for heavy-duty applications, while the matrix material provides the toughness and strength required to withstand the stresses of use.

Tungsten carbide, also known as cemented carbide, is a composite material made by combining tungsten metal powder and carbon. Tungsten carbide is one of the hardest metals commercially used today. It scores about 9 on the Mohs hardness scale, which is slightly higher than titanium, chromium, and cobalt alloys. Tungsten carbide rods are widely used for creating premium solid carbide tools, such as end mills, drills, reamers, milling cutters, stamping, and measuring tools in different industries. KoneCarbide manufactures top and consistent quality carbide rods in varied grades including KS25, KS27, etc. We supply both unground and ground carbide rods.

Copper Tungsten Carbide Composite Brazing Rod Max Carbide

Tungsten carbide, sometimes called carbide, is harder than Corrosion-Resistant Tungsten with excellent wear resistance. Use it to machine long-lasting tools, such as end mills and inserts.. Rods with a coolant hole let coolant flow into tools that need it, saving you the effort of drilling a hole yourself.. For technical drawings and 3-D models, click on a part number. The brazing carbide is used to produce highly wear resistant tungsten carbide composite rod, also called tungsten carbide brazing rod. Tungsten grits and tungsten tube metals will help you make your metal even more durable and wear-resistant. Shop for tungsten brazing rods today!