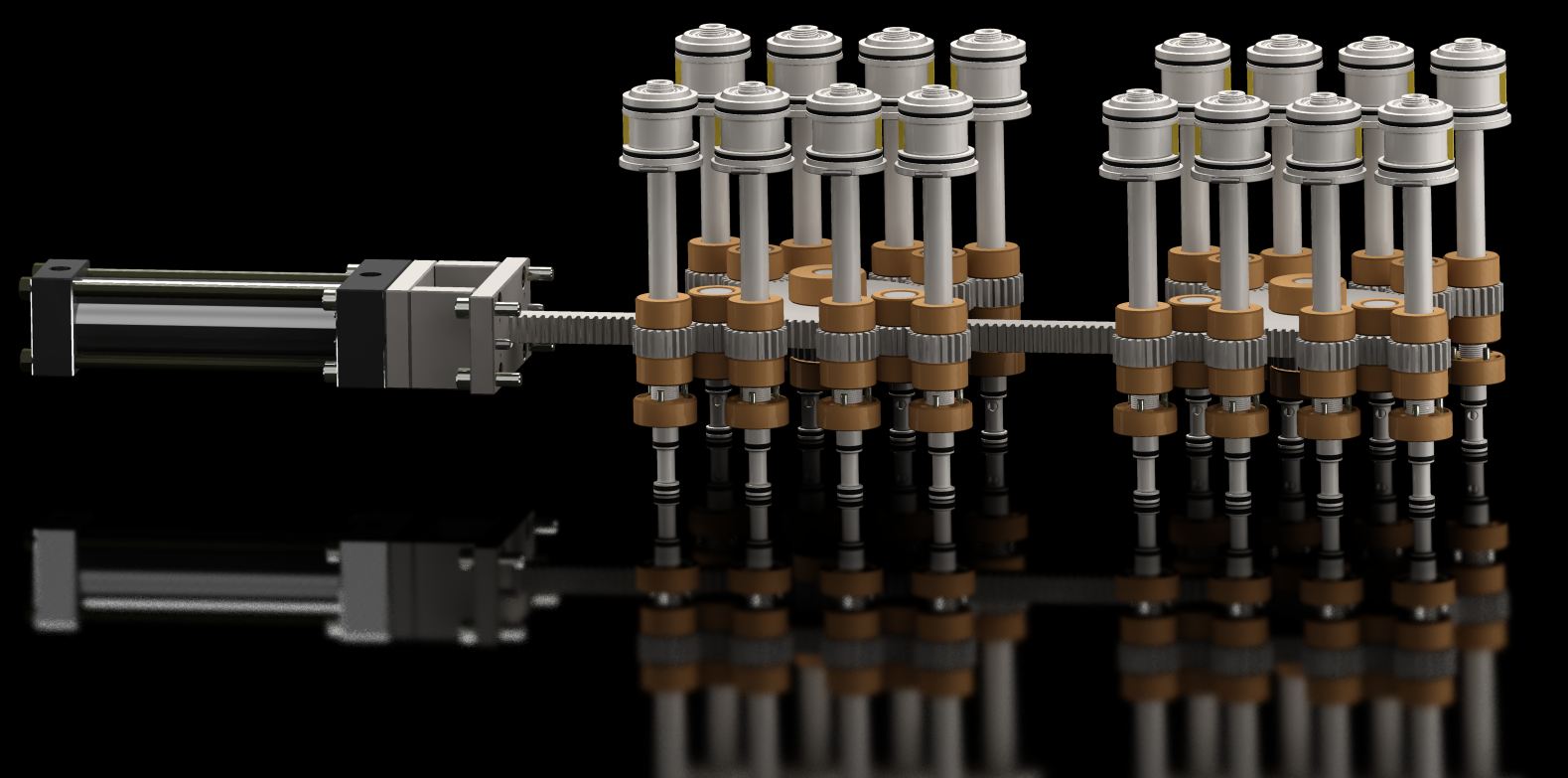

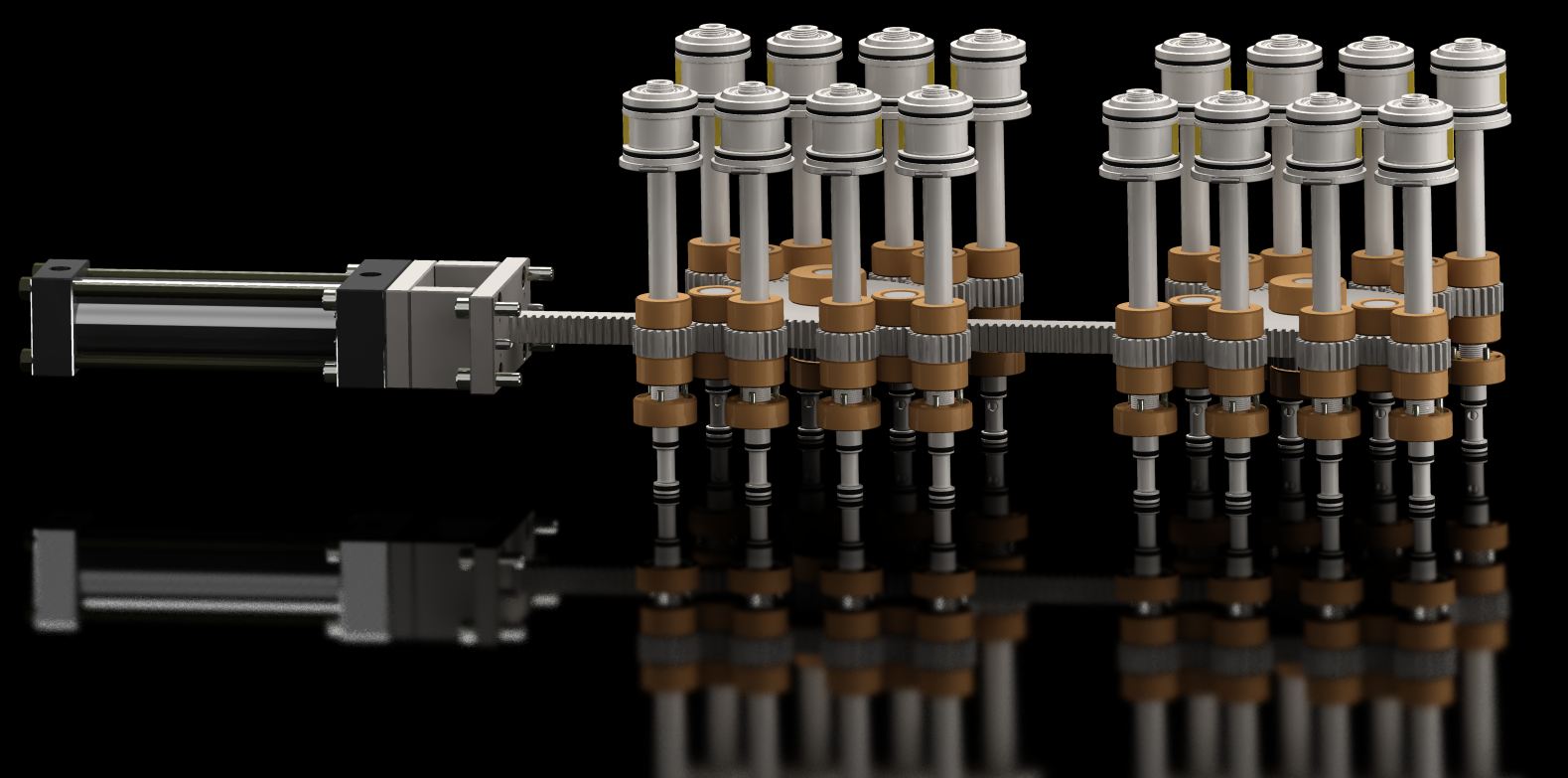

Unscrewing molding is a one-of-a-kind injection molding process that produces threaded components through mold technology that incorporates movement and rotation. This kind of mold is crucial in the production of: Medical supplies Sprinkler and showerheads Bottle and milk caps Prescription medication bottles Servomold Unscrewing Device Featuring Threaded core, guide thread nut and cooling insert with sealing can be dismantled for inspection or maintenance on mounted mold from the parting line. Threaded core, guide thread and cooling insert with sealings. System Design 1 gearbox level or 2 gearbox levels

Unscrewing Mold Designs

A quality design for Automatic Unscrewing mold injection molding ensures the final product is high in precision and quality. Hydraulic Unscrewing Device Without guiding thread with cam interlocks areas dotted following application notes are to assist in the selection of drive gears and the D-M-E Hydraulic Cylinder components associated with Unscrewing mold applications. For any quoting of custom mold or tooling to creat your plastic parts. Please visit www.longterm-mold.com, or email:

[email protected] 7 Min If necessity is the mother of invention, it surely applies to the PERC system. Its inventor needed a way to solve a huge problem for a customer—and invented it. Unscrewing molds can be a bear to operate.

Unscrewing Mold Designs

Unscrewing molding is a unique injection molding process with mold technology that includes movement and rotation to produce threaded components. Some plastic parts such as caps and closures with detailed threads cannot be removed using standard knock-off methods. Unscrewing-core tooling with hydraulics uses a rack (a linear, toothed rail) that is usually mounted atop the mold. The toothed grooves of the rack enter the mold through the top and intersect with spur-type gears inside, which turn the core. A hydraulic cylinder moves the rack to turn the core. The strip thread mold design is not robust enough to provide a leak proof result. There are Primarily Two Types of Unscrewing Molds: The first type is known as a reciprocating core. This type does not require the stripper action to take part in unscrewing. This type of unscrewing mold requires racks, gears and hydraulic cylinders. Chapter 13: Automatic Unscrewing Mould Tool Design. 13.1 Introduction. The invention of the screw thread is arguably second in importance only to the invention of the wheel. Although there have been many developments in fastening technology since the invention of the screw thread, it remains as the primary method of securing parts in countless.

Unscrewing Injection Mold Design with sliders study case UPMOLD

This video is about an automatic unscrew thread injection mold. Automatic unscrew thread injection mold is used for plastic parts with internal thread. Exter. MG Mold August 5, 2016 Injection Mold Design One of the most unique types of injection molds are theunscrewing molds. They are part of everyday use, which may cause you to think that you won't need to spend much time considering the required design.

Unscrewing Core Design Provides Fast, Accurate Core Positioning Although PERC (Programmable Electric Rotating Cores System) is not a brand-new technology, it warrants a second look as a way for moldmakers to provide another value-added service to their customers. A two-cavity PERC unscrewing mold for a medical part. Images courtesy of B A Die Mold. Published 12/1/2002 Unscrewing Components: One Good Turn Deserves Another Choosing unscrewing components for your molds shortens leadtimes, reduces component costs and decreases cycle times. Sherry Baranek Contributing Writer, MoldMaking Technology magazine

Unscrewing Plastic Mold Design with rotary driving case UPMOLD

unscrewing injection molding design of mould tool plastic mold April 27, 2014 mould tool, plastic mold At the place that the mould tool opens prior to an unscrewing operation, the piece will be kept on the shifting part of the mould tool. In cases like this, it is very important to shape the keying characteristics on the base of the part . Seals are molded from flexible PVC with undercuts greater than .375 inch and a 1.500 diameter, resulting in undercuts of 25%. Modified Closure Manufacturer's Association (CMA) threads are frequently stripped on closure sizes above 24mm in polyethyl-ene and polypropylene, especial-ly in co-polymers.