Complete your free online smile assessment and find the instasmile that's right for you. Get 30% Off Plus Free Extras Worth £250 - Use Code HAPPY30 All veneer sheets are available with different backing options (including custom peel-and-stick backing). For more information on wood veneer backing options or advice on how to apply, get in touch with us at 800-426-6018 or send us a message at

[email protected]. Before you purchase your next order of oak, ash, or beech veneer sheets.

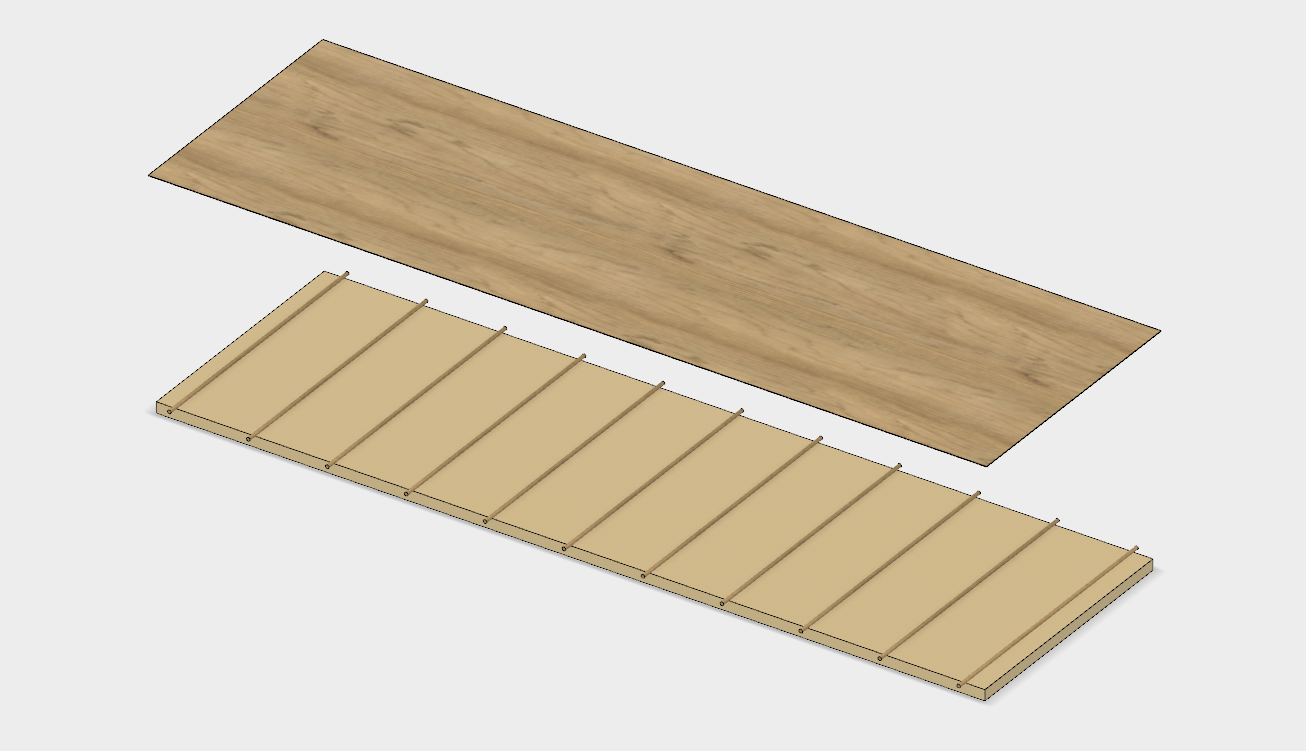

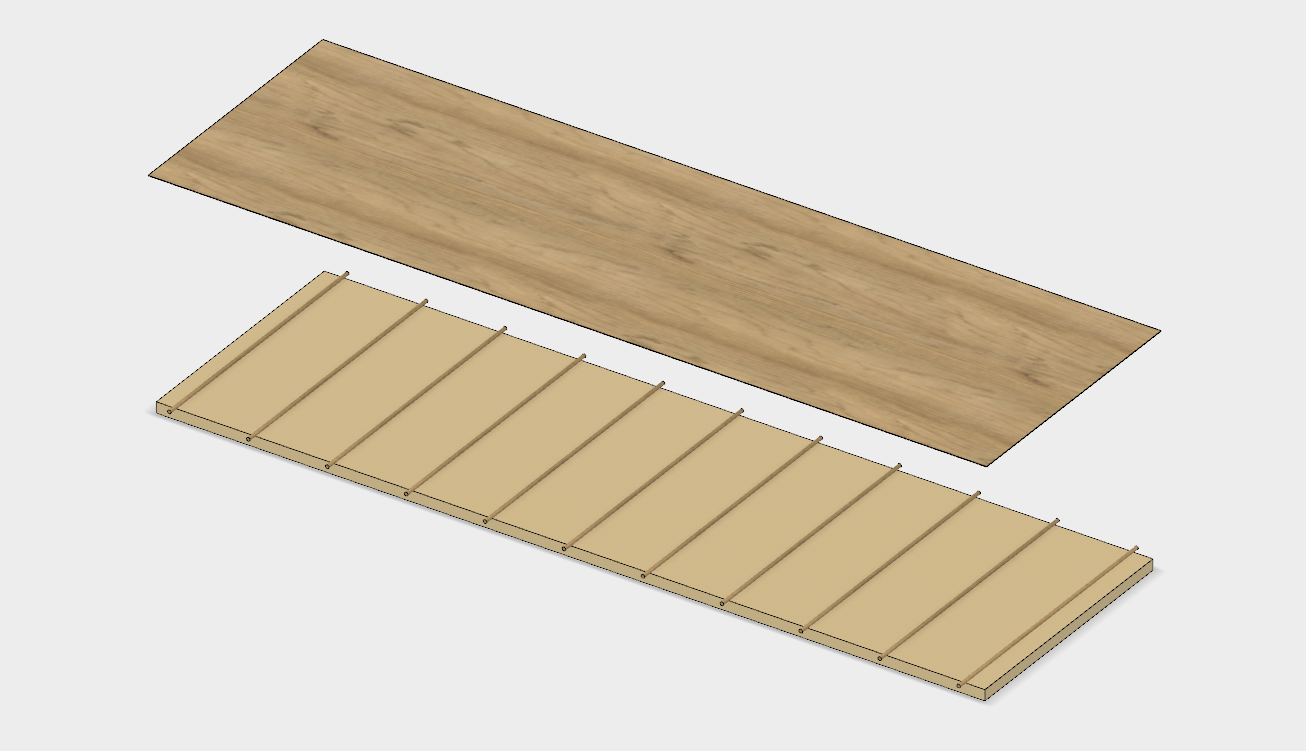

How to Apply Wood Veneer with Backing Popular Woodworking

Paper & Backing Veneer. As veneer is usually approximately 0.6mm thick it is fragile. To ensure the veneer's stability it needs to be pressed onto a substrate such as MDF, chipboard or plywood. Substrates will warp if you only veneer one side thus the need for a backing. The backing is also known as a "balancer" or "compensator". We. A backed veneer won't need to be flattened; it's ready to apply immediately. Always cut your veneer slightly larger than the substrate. You'll trim it to size after it's applied. For a 25-1/2" x 84" countertop, you might want to cut your veneer to 26-1/2" x 85.". Apply a thin, even coat of contact adhesive to the backing and the. Wood Veneer UK specialise in supplying you with a choice of the world's finest quality wood veneers by Mail Order. We offer a wide range of Marquetry Supplies, Paper Backed Wood Veneers, decorative veneers and exotic wood veneer species. All our veneers can be purchased as single wood veneer sheets for your convenience, and are ideal for. Paper Backed Wood Veneer. Decoflex Paper Backed Veneer is an innovative veneer product using the latest in technology with natural veneer to create a easy-to-use, flexible veneer sheet. All of our Decoflex sheets are sized at 244cm x 122cm ( 96" x 48" ) and the overall thickness of Decoflex is between 0.4mm and 0.6mm.

Backing Timber Veneer (Birch) BV06X8 Australian Premier Veneers

For paper-backed veneer Test the back of the paper backed veneer by applying a single drop of water to the backing. If there is still a bead of water after 5 seconds, then the backer is creating the problem with the adhesion. The solution is to scuff sand the backer with 80 or 100 grit sand paper. Center the selected pattern section over the substrate panel and apply the contact cement, following the manufacturer's instructions, to both the veneer and the substrate. Allow it to set. Be sure to mix the adhesive thoroughly before applying it. This will maximize its effectiveness. Backing Veneer is a real wood veneer permanently bonded to a paper backing. This backing is applied to keep intact the individual wood veneers used to make up the full width of the sheet. Home Decorative Surfaces Veneer Backing Veneer . Showing all 3 results. Show sidebar. Show 9 24 36 When the moisture content of the veneer changes, it will place stress on the substrate. By balancing the panel with a veneer on the back side, those stresses are kept even and the panel will stay flat. When to Apply a Balance Veneer. A balance veneer can be applied immediately after the face veneer comes out of the press.

Fleece Backed Veneer How to Make Fleece Backed Veneer Sheets and

Decoflex are flexible wood veneer sheets, obtained by first pressing real wood veneer on a paper backing and subsequently breaking the wood fibres. The surface is sanded with a 150 grain sandpaper and is ready for use. Decoflex can be laminated easily and is perfect for use in production of doors and other furniture components. In Europe, the. The HPLT pressing process (High Pressure Low Temperature) that Decospan applies guarantees the highest quality for each type of panel. This unique method is the result of our decades of experience in pressing methods and veneer processing. When ordering a veneered panel, it is essential to select the right base board and the right backing.

http://www.OakwoodVeneer.com - In this episode, production manager for Oakwood Veneer, Jay White, talks about the different types of backers that are availab. We are always happy to help. Veneer jointing or stitching is the process of joining veneer leaves together to form a fixed-length sheet of veneer known as a layon, sometimes also known as skins or faces. As the name describes, the layons can then be laid onto a substrate to create a veneered board which can be used for doors, furniture.

Veneer with 10 Mil Paper Backing, 1' x 8' Roll Rockler Woodworking

Simon There used to be a veneer backing paper called Yorkite available in brown for backing curl veneers and white for backing Sycamore and light veneers to reduce telegraphing, If you are still looking I would suggest you contact Crispin's. I have never used it but we joint veneers using various techniques and sell the products we use, these. Paper Backed Wood Veneer is an innovative veneer product using the latest in technology with natural veneer to cr. View full details Original price £34.99 - Original price £89.99 Original price. £34.99 - £89.99. £34.99 - £89.99. Current price £34.99 Choose options.