This is exactly the function of the HMI. Human Machine Interfaces (HMIs). Presumably, this bit gets its data from a coil in the PLC's ladder diagram program. However, since it also appears in the HMI database with read/write permission, the potential exists for the HMI to over-write (i.e. conflict) that same bit in the PLC's memory.. The PLC then sends a specific fault number to the HMI, and a special display block is used to display the message associated with the number received from the HMI. Figure 5. HMI with a complex P&ID (piping and inst diagram) for a large reactor process. Image used courtesy of Adobe Stock . Bringing It All Together

Starting an HMI design? Here are four things to watch Electrical Engineering News and Products

HMI Entry Tier Block Diagram NXP Technology Non NXP Technology Optional Technology MCU/MPU MIPI DISPLAY Temperature Sensor DRAM DDR RS485 CAN Analog in Eth PHY Eth PHY Eth PMIC Load Switch Eth Digital IOs NFC Wireless Connectivity Security (Edge Lock Discrete) Real-Time port TSN or Ind. Eth. Real-Time port TSN or Ind. Eth. EdgeLock Security i. This guide reviews the fundamentals of Human Machine Interfaces (HMIs) for motion control and industrial automation applications. We explain what HMIs are, the history of the HMI, where and why HMIs are used, typical HMI applications, how to select an HMI, how to wire an HMI, HMI and PLC connections, HMI programming and software, environmental considerations, as well as the advantages and. HMI panel Block diagram. Overview. Our integrated circuits and reference designs enable you to build HMI systems to create a smooth and realistic 3D experience. Today's HMI systems require high-performance processing with hardware accelerators and optimized power consumption. Our portfolio of Arm-based microprocessors and analog components. Chapter 1 4 HMI HANDBOOK Here are a few more benefits HMIs provide by interfacing seamlessly with a PLC-based control system: Line/Bar Graphs - Display real-time process values over time with line graphs or in easy-to-read bar graphs. Data Entry - Easily change process variables with a pop-up numeric keypad on the screen or with increment/ decrement arrows.

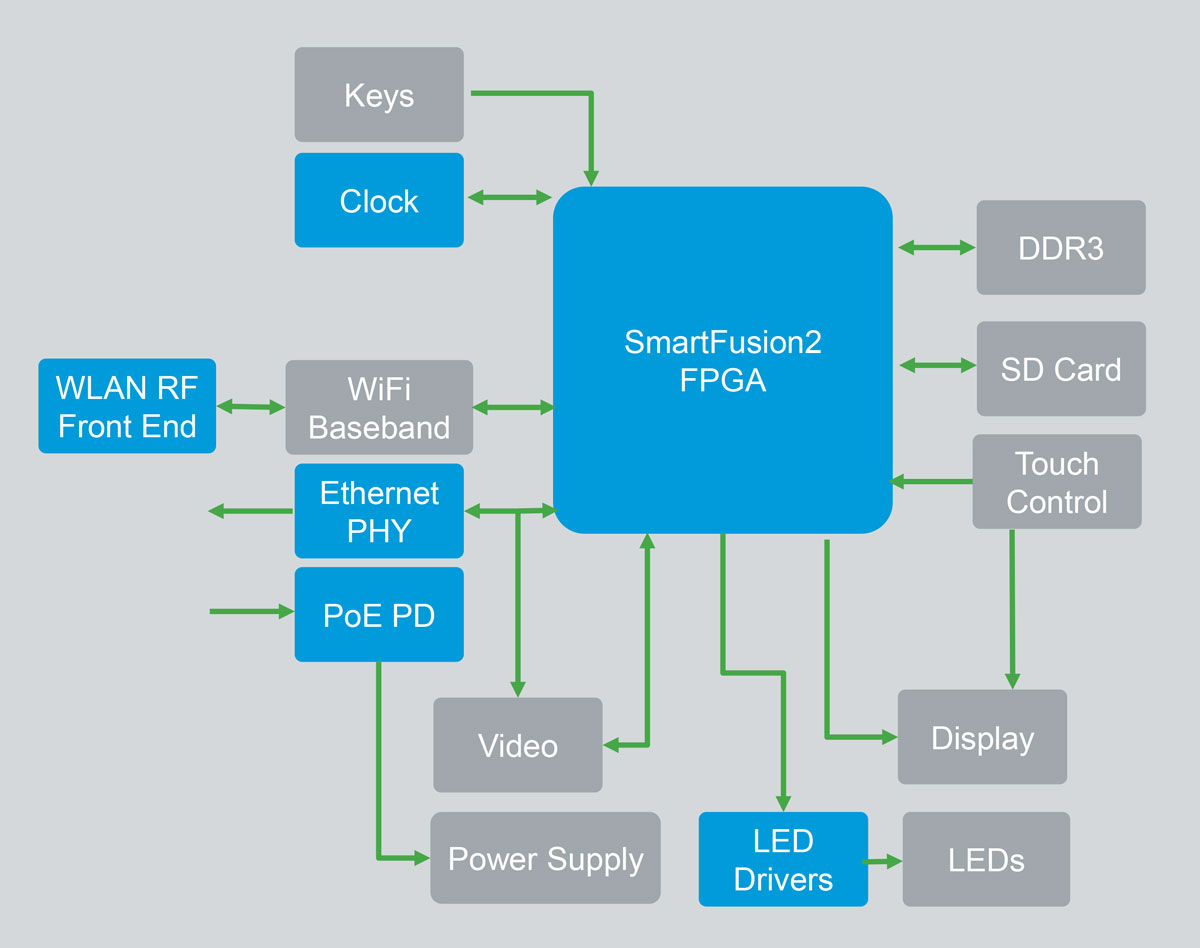

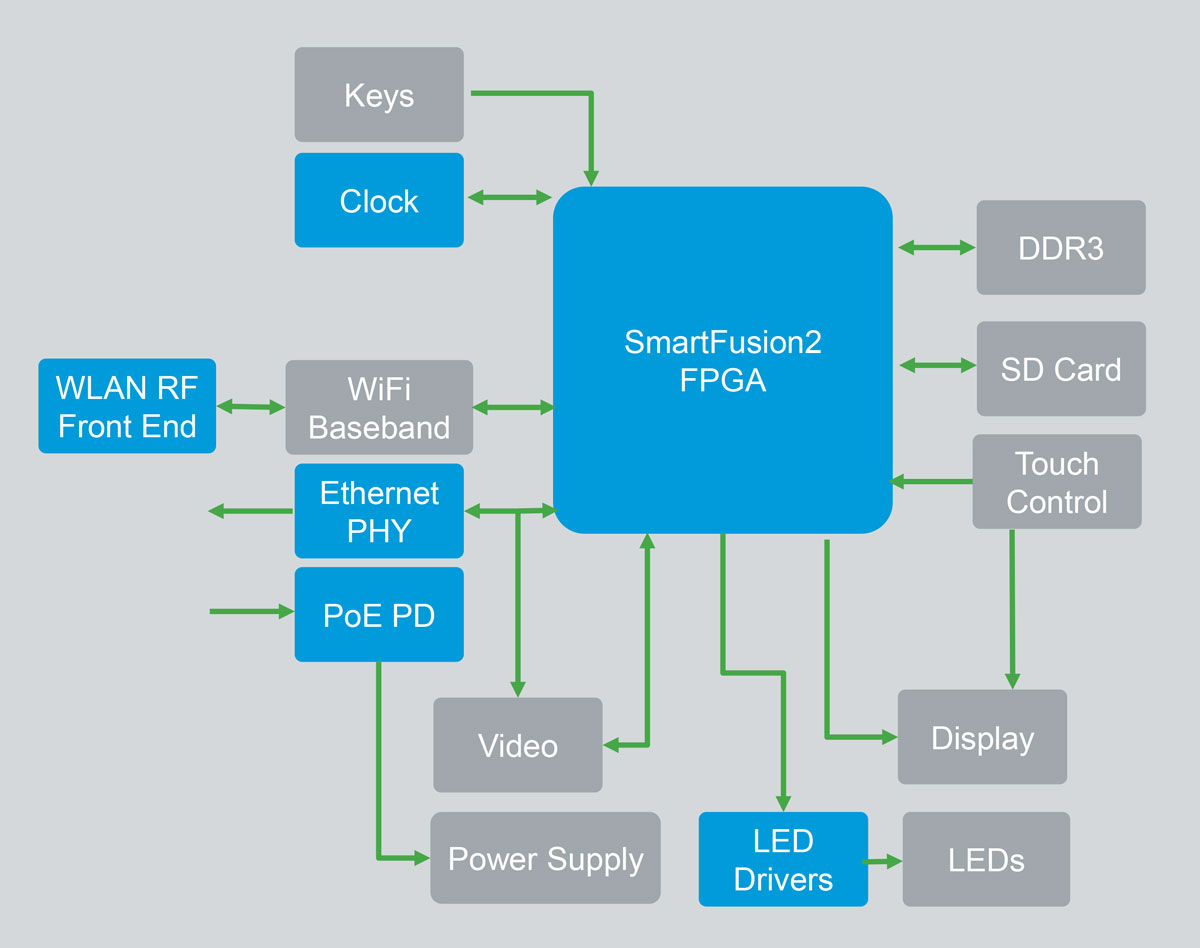

Vision of the HMI platform block diagram. Download Scientific Diagram

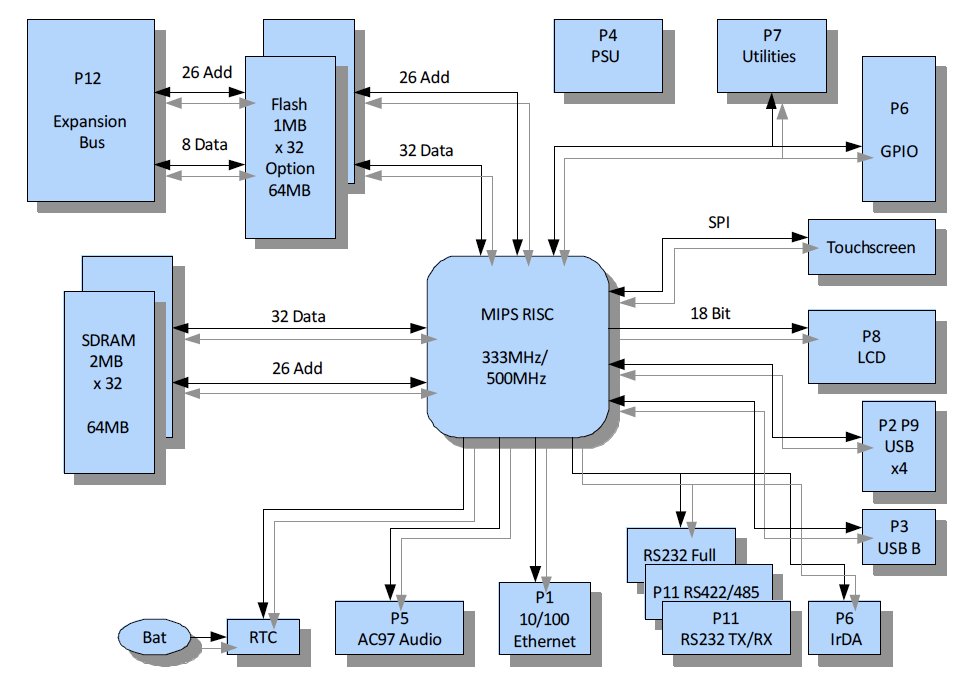

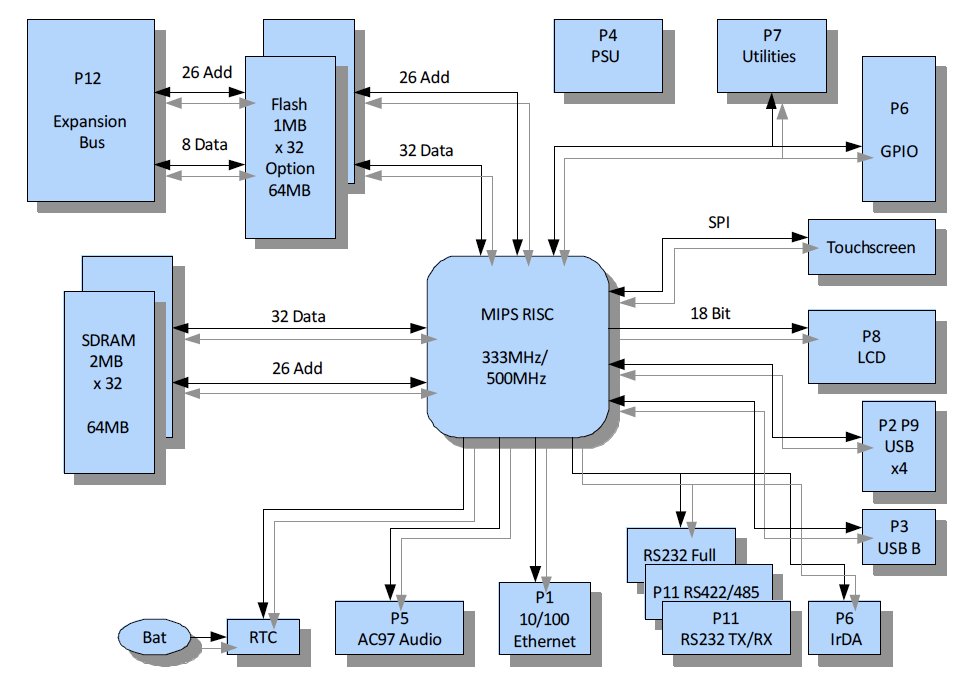

Become well-versed with the tools available in the Siemens TIA toolbox and write PLC and HMI code effectively. Next, you'll develop logic in all of the languages that TIA Portal offers, such as Ladder, Function Block Diagram, and Structured Text (SCL) (note that Statement List is not covered as a deprecated language), as well as the newest. The HMI controller block diagram is an engineering development tool used to convey a complete product design using graphics. The block diagram also makes it easier to plan the breadboard for prototyping and testing of the HMI controller in a maker's workshop or laboratory bench. A final observation of the HMI controller block diagram is that. Industrial HMI Last Updated: Dec 8, 2021 Powered by an industrial grade i.MX microprocessor, NXP provides HMI solutions for harsh industrial environments. These devices are power-on tested to emulate years of 24/7 operation for critical applications where accuracy, performance, and operational longevity are important factors. • Block diagram • HMI • Links between devices (LAN, station bus, process bus) • Details of connection points • Devices locations • Networking devices • Collateral IEDs (such as protective relays and external alarm annunciator) • Time signal circuit • Details of communication path to the remote control center • List of.

Applications HMI (Human Machine Interface) Microsemi

Figure 3: Block diagram of a typical HMI system using an HMI controller. Figure 3 shows a more detailed diagram of such a system. For HMI applications with capacitive-touch buttons, we can abstract the functionality to two safety functions: Ensure that a touch event really results from a finger touch; Download scientific diagram | Block diagram of automation packaging system pro-face remote HMI [8]. from publication: Implementation of Programmable Logic Controller in multi machine operations.

Intrusion HMI panel Block diagram. Overview. Our integrated circuits and reference designs help you create an intrusion human machine interface (HMI) panel design that serves as the primary interface to a home security system. Design requirements. Modern intrusion HMI panel designs often require: Context in source publication. Context 1.. block diagram of the above HMI (front panel) is shown in Fig. 3: The block diagram of the HMI mainly shows the method of serial communication using.

Linuxready SBC targets HMI development

Block diagram (SBD) for Single Board Computer, Human Machine Interface application equipment. Posted on November 6, 2013 by Electronic Products Design Considerations.. • HMI: A Human-Machine Interface (HMI) system's usability is determined by the its processing power, its ability to render complex and reality-like screens, its fast. The Pulse Timer controller electrical wiring diagram. Image used courtesy of the author . The schematic and diagrams shown in Figures 6 and 7 reference the M5Stack Core and the relay module dry contact wired to the Arduino. Figure 7. The M5Stack Core-Pulse Timer controller electronic circuit schematic diagram. Image used courtesy of the author