The four most common coal pulverizers types are: Ball-Tube Mills This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Coal Pulverizer Machine, कोल पल्वराईज़र Zoomlion, Hyderabad ID 8551450333

pulverizer is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal combustion in the steam-generating furnaces of coal power plants. Types of coal pulverizersedit. Coal pulverizers may be classified by speed, as follows: [1] Medium Speed. High Speed. Are you looking for a direct-fired coal pulverizer, a low-capacity coal size reduction machine, or something in between? Williams has you covered. At Williams Patent Crusher, we set ourselves apart from other crusher and pulverizer companies. This is done with our diverse product line and customized systems for a variety of applications. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classification functions. The classification function plays the important role of ensuring that only fine particles are sent to the boiler. 35K views 13 years ago Here's a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in the field today..

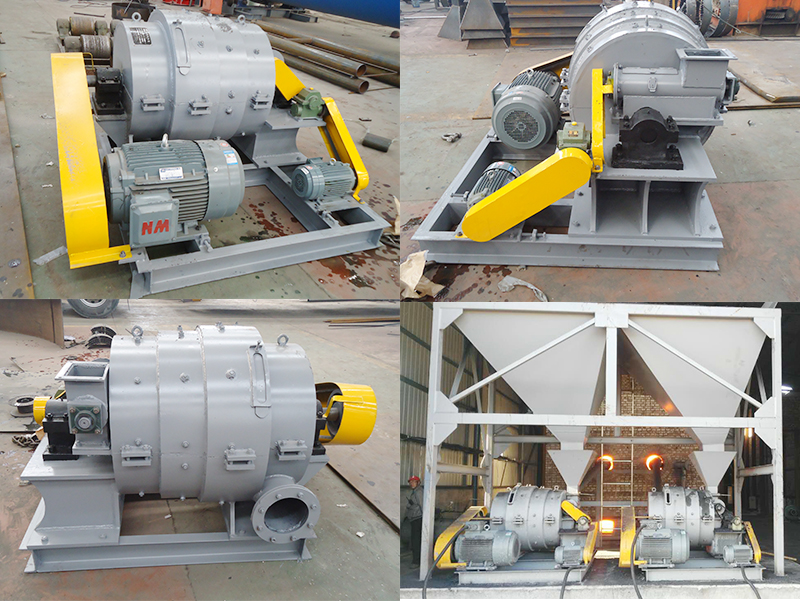

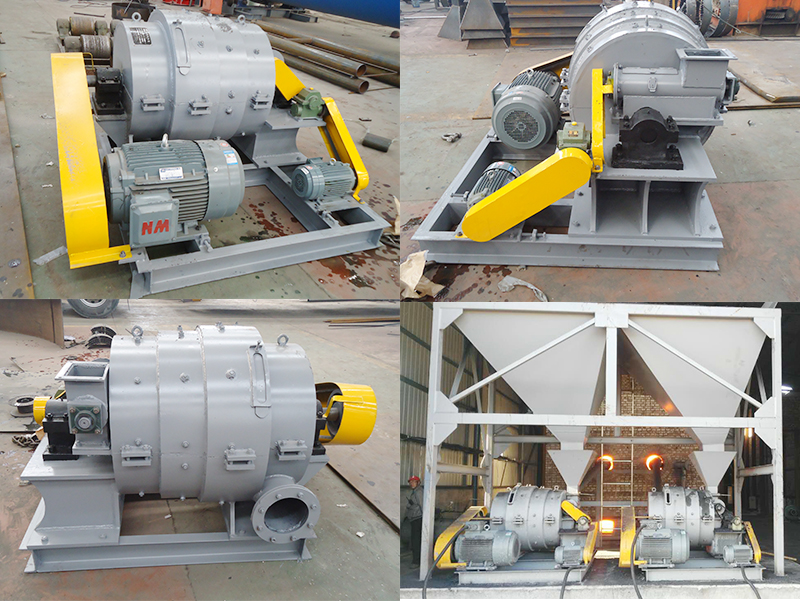

China Coal Grinding Mill/Coal Mill Pulverizer/Coal Pulverizing Machine China Coal Mill

tion, particularly when pulverizing high moisture and/or oversize coal. A TRITA Pulverizer The ATRITA pulverizer is a high-speed, compactly designed machine which reduces raw coal to pulverized coal by the combination of crushing, impact and attrition. The AT RITA has separate crusher, pulverizer, Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification. coal limestone phosphate rock pigments tobacco clay barite gypsum Williams Crusher pulverizers have many possibilities. If you don't see your application listed, our sales engineers can help you find the right machine for your needs. One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal. Read More.. Stedman Machine Company has produced quality, reliable and durable size reduction and industrial crushing equipment. Stedman has expert field service and installation technicians.

China Coal Pulverizer Machine Manufacturers, Suppliers Cheap Coal Pulverizer Machine for Sale

Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size. As a premier industrial crushing equipment manufacturer, Stedman Machine Company provides consulting services, custom designs, project planning, and more. Contact us!. One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal. Read More.

In the first computational example the coal pulverizer drive system is considered. This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary gear of the resultant ratio 1:5.33. The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass.

Coal Pulverizer Machine DONGDING DRYER

Pulverizing Mill Solutions Pulverizer mills are mechanical devices that grind various types of materials, processing them in batches or through continuous acceptance on a conveyor. What Is A Coal Pulverizer? Pulverization is currently the most preferred method for preparing coal for burning. Coal Pulverizers help to mechanically smash and grind coal into a fine powder, enabling it to be burnt like gas. This increases the efficiency of combustion.