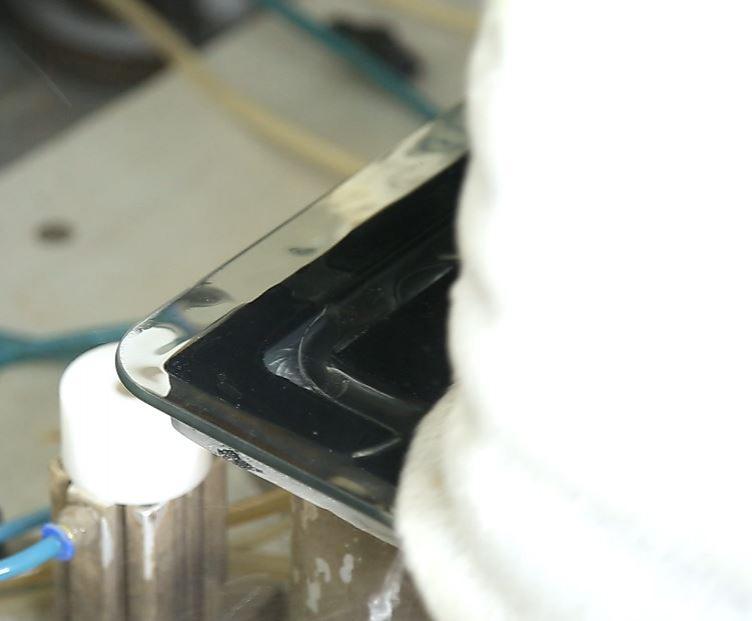

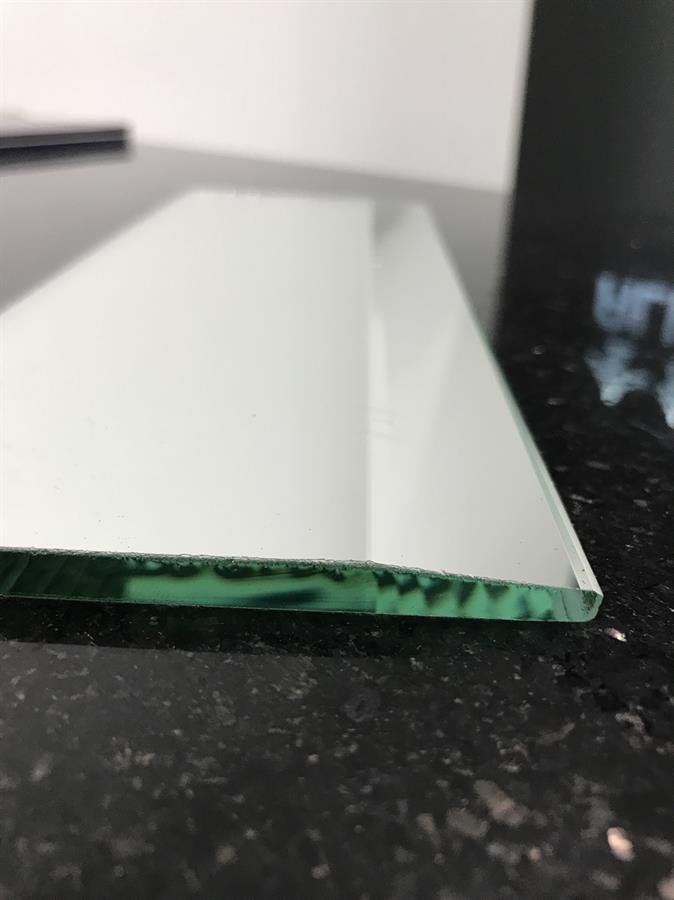

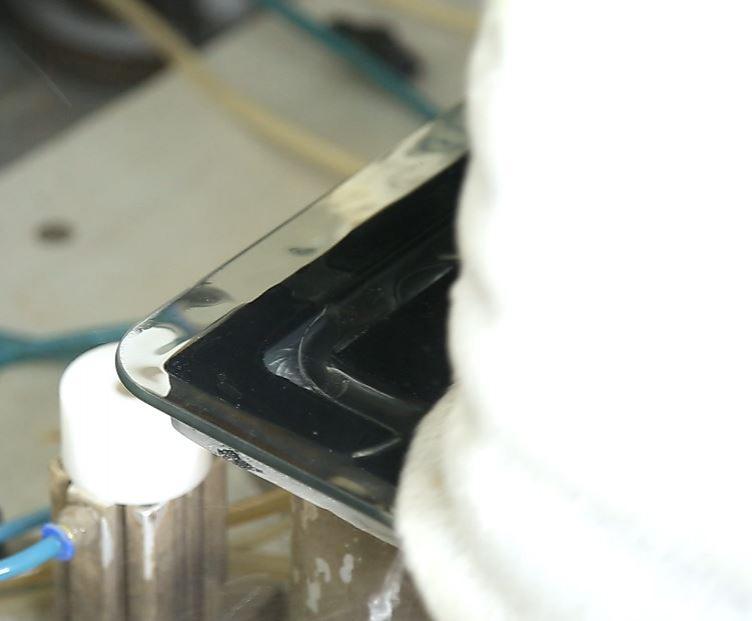

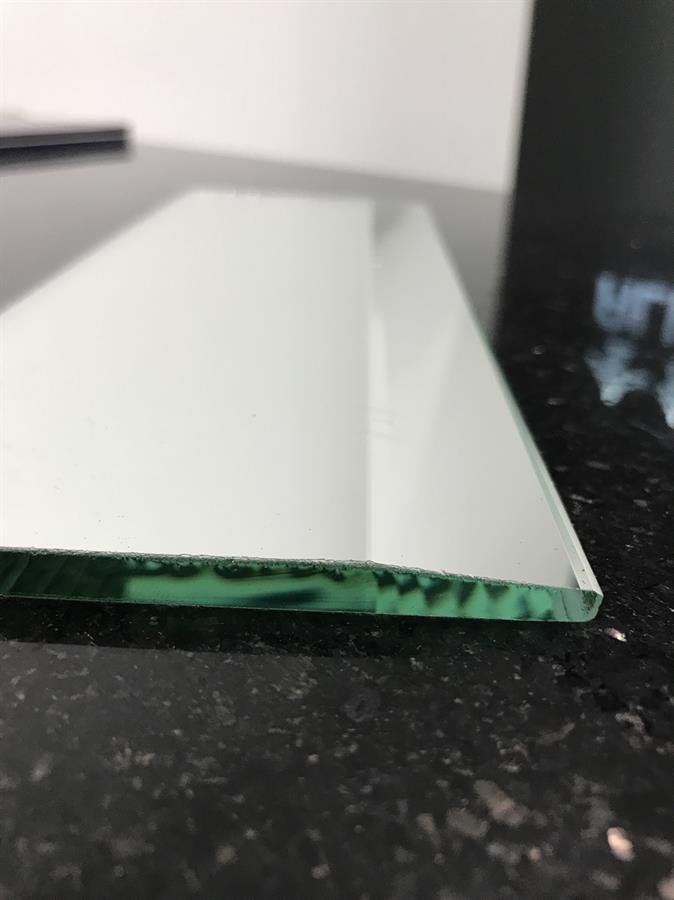

1. Flat Edge: The flat edge adds no roundness, but the edges are polished to present a sleek, clean appearance. A chamfer is added at the transitions of the piece's edges to prevent sharpness. Flat, polished edge glass is most often used for custom-made or thick glass table tops. Glass edging is the fabrication process of grinding and shaping raw, jagged glass corners into a smooth, finished texture. It is highly specialized, and best handled by an experienced fabricator with professional equipment and operators, such as Dillmeier Glass Company. Glass Edging Benefits

Glass edging knowledge

The five most common edge treatments for glass materials include cut and swipe (seamed edges), grindand chamfer (bevel), pencil grind, pencil polish, and flat polish. Glass edgework is the process of sanding the edges of the glass to finalize the piece. There are multiple reasons why you might want to consider different types of glass edgework. For example: if you want a decorative piece of glass to display throughout your home, then you would want either polished or beveled edges. Edging your glass or mirror involves creating a finished look along the sides of a piece and includes beveling as one of its styles. In edging, however, the glass appears to have a more step-like formation in the way it is cut to create a different fashioned edge that offers a grander variety of appeal to your personal space. GlassArt Design can finish off your glass project with machine cut flat edge, beveled edge or seamed edge and more glass edge finishes for that perfect fit. Or, for a more unique glass edgework design, we specialize in a variety of edge finishes, ranging from jagged edges to a tapped edge to nibbled and broken edge finishes.

Glass Machinery and Accessories Supplier Ervin Sales Group

What is glass edging? Finishing the sharp edges of cut glass enhances the glass through chip reduction, safe handling, and even custom design elements. Our machinery and glass artisans make refined, smooth edges, and can even add dimensional details to glass and mirrors. Glass Edging & Edge Finishes - Abrisa Technologies Get a Quote Minimum Substrate Thickness 0.020" (0.5 mm) Maximum Substrate Thickness 1" (25.4 mm) - will have overall size limitations Tolerances ±0.001" to ±0.010" dependent upon size and shape of glass parts Maximum Substrate Size 10" x 60" (2794 mm x 1524 mm) up to 6 mm thick at this size We are a Miami-based company dedicated to the art of transforming glass into masterpieces of both form and function. With a relentless pursuit of perfection, we combine cutting-edge technology with skilled craftsmanship to deliver tempered glass solutions that exceed expectations. The advantages of the vertical KSR edge seaming system at a glance: Compact construction means significantly less space is required compared to horizontal design. Only 1 grinding head with diamond grinding belts. Very short cycle times - further cycle time reduction of 35% when used in combination with KSV.

Curved Glass Edging Bevel Edge Dexin

CNC Glass Edging: Our precision grinding stations are extremely versatile, offering a wide degree of flexibility in our process design. While the illustrations depict the most common edge and corner specifications, we can custom design and produce nearly any edge or corner profile to meet specific application requirements. The vivid, sharp look of Hard Edge glass art starts with clear design & colour ideas - with precise drawings to back them up - rather than inspired impulses for how shape and colour might look as the work progresses. Hard Edge work begins with pencil sketches which are developed into firm designs - before ever a piece of glass is cut.

In such cases, rounded edge finish like pencil polished or beveled edges can be safer options compared to sharp, unpolished edges. 5. Blend with Your Decor: Ensure that the selected edge type complements your existing decor and furniture. The right choice can seamlessly tie your pentagon glass table top into the overall interior design. 6. Simply place your piece of glass on top of the sanding disk and run it back and forth in an up-and-down motion until smooth. This method works especially well for small pieces of glass that can't fit inside of a belt sander or won't fit on top of a block made for smoothing glass edges. 4. Use a hand sander.

Glass Edging Building Materials Online

In a six-story building in the city's center, Michael and Petra Mayer run — and reside in — one of the world's oldest and most celebrated architectural glass and mosaic studios. The Mayer. Glass Edgework Types Here are some of the most common types of glass edgework: Seamed - This is the standard edgework option and is fairly basic. It's also the easiest and cheapest form of edging. It's safe, but there can be some defects in the edging that affect the aesthetics of the piece.