Custom Prefab steel Arch-Style Building Kits. Easy DIY Set-Up. Free No-Hassle Quotes. Custom Prefab Steel Arch-Style Building Kits. Quick & Easy DIY Set-Up. Free & Fast Quotes. 4. Finish pouring the concrete and let it set for 24 hours. After the metal reinforcement is set, fill the wood forms the rest of the way with concrete and then brush off any excess to ensure the surface is perfectly flat. Allow the concrete to cure for at least 24 hours before doing any more work on the structure. 5.

Easy Steps for 3D Home Architect Design Southern Pride Painting llc

**Plans sets are now available!! (Includes pdf, .plan, and .dxf files) Start Building your own Modern Mountain Getaway! https://gum.co/WKyoRThis is the first. Step 3: Research and hire the building team. Building a home is a huge project, and the average build will involve 22 subcontractors working on the home. The first person you'll need to hire is the general contractor or a custom home builder. They will oversee the construction of your home from start to finish. Make alterations to the site's topography if necessary to alter the water flow across the site: This often requires a contractor with earth-moving equipment. Order a dumpster to handle refuse during the building project. Order one or more portable toilets for the workers. Order temporary utilities from the power company. Download Article. 1. Join the base panels to the bottom structure. Align and glue the base panels so that one flat face is flush with the back edge of the panel and the other is 3 in (7.6 cm) back from the front end. Then, using butt joints, screw through the cabinet base and into the edge of the panels.

How Much Does A Brick Wall Cost To Build In 2023? Checkatrade

April 24, 2023, at 10:12 a.m. Building a New Construction House. More. Whether you're a first-time homebuilder or have some experience under your belt, here's what you can expect when bringing your vision to life. (Getty Images) Building a new construction house is an exciting experience that allows you to build your dream house from scratch. 1. Gather Your Tools. You might be able to get by with a screwdriver from your junk drawer, but if you're spending a bunch on a new PC, get a nice tool kit to go with it. You'll use it for not. Cost Breakdown. The average cost for drywall is $1.50 to $3.00 per square foot, with the cost per panel ranging from $60 to $90, including labor and materials. Once the drywall is up, the walls and ceiling can be textured, which averages from $1.15 to $1.35 per square foot. Build this handy stool in one hour and park it in your closet. You can also use it as a step to reach the high shelf. How to make storage shelves: All you need is a 4 x 4-ft. sheet of 3/4-in. plywood, wood glue and a handful of 8d finish nails. Cut the plywood pieces according to the illustration.

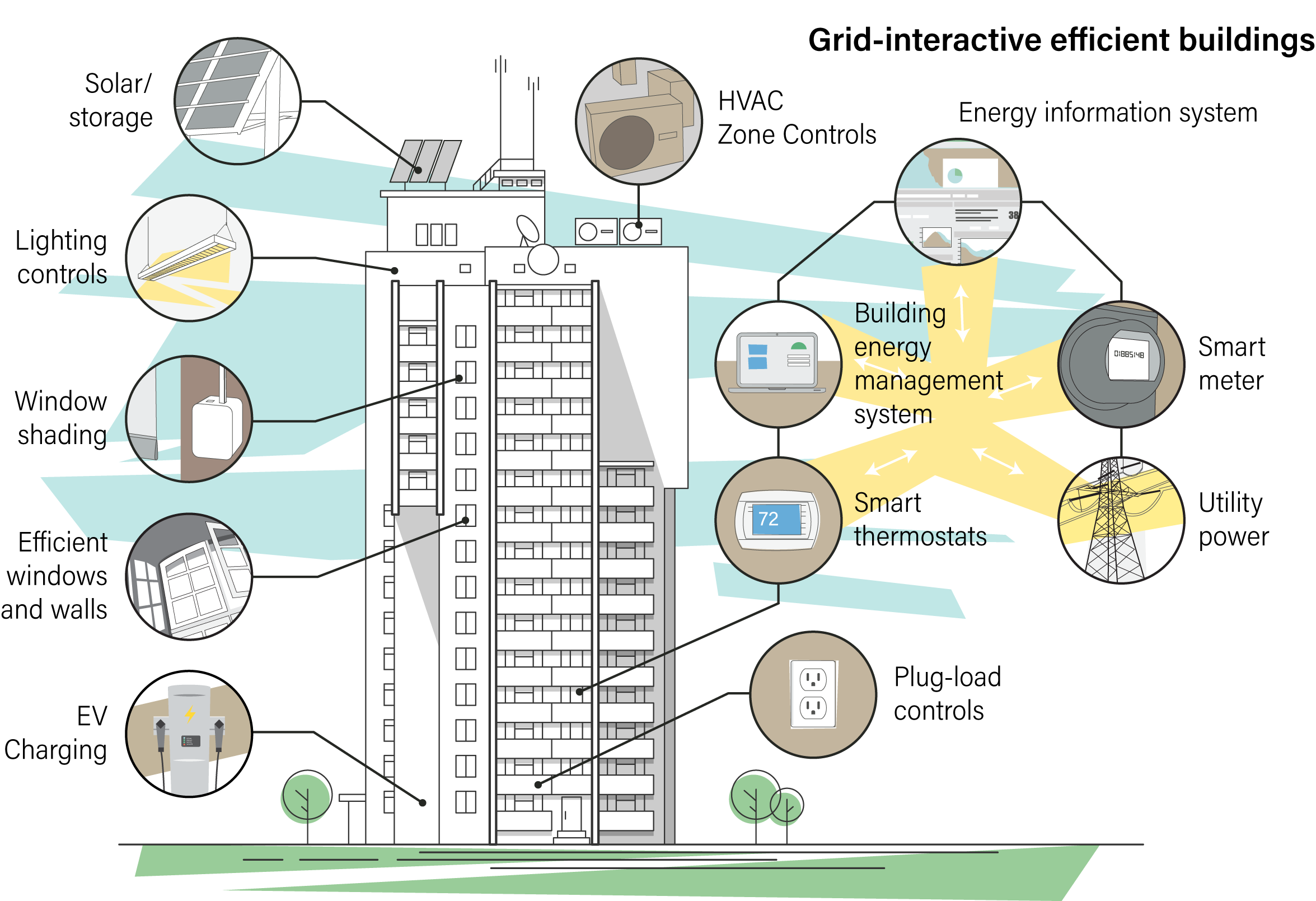

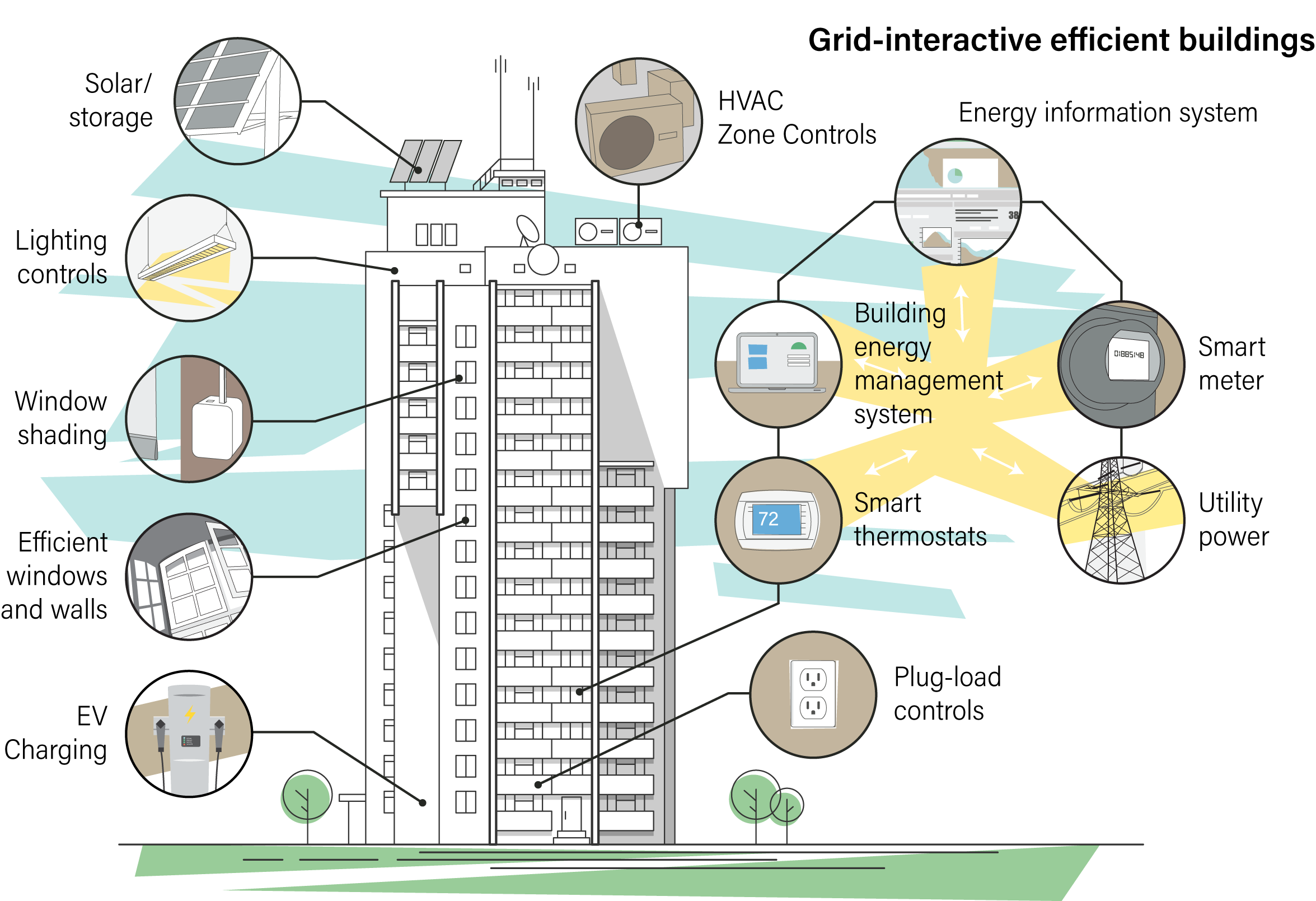

Gridinteractive Efficient Buildings Are the Future, and Utilities Can Help Lead the Way ACEEE

The second-floor space is 176 square feet for a guest bedroom. The building plans cost $1,600 for PDFs and $2,100 with CADs, including the materials list, construction notes, and plans for the foundation, plumbing, roof, elevation, HVAC, electrical, doors, and windows. Square footage: 1,410 square feet. Bedrooms: 3. 7. Column Construction. After the construction of the foundations and plinth beams is present, a reinforced concrete column would be constructed. The procedure involves constructing a column kicker, placing steel bars, setting up formwork, pouring concrete, and curing the concrete.

The planning in building construction involves three major steps: Developing the Building Plan. Analysing the Finance. Selecting the Construction Team. Once the site where the building project is indented to construct is chosen, the expertise of engineers and architects are taken to develop the site and the building plan. Make an Easy Knife Block. This handsome knife block is fast, easy, fun to build and includes a 6-in. wide storage box for a knife sharpener. To build one, you only need a 3/4-in. x 8-in. x 4-ft. hardwood board and a 6-in. x 6-1/2-in. piece of 1/4-in. hardwood plywood to match. Begin by cutting off a 10 inch length of the board and setting it aside.

Introduce 55+ imagen building background knowledge Thpthoanghoatham.edu.vn

Subtract that number from the case width. Cut the cabinet bottom to that length. For example, to make a cabinet 33 3 ⁄ 4 " wide using 3 ⁄ 4 " plywood, cut the case bottom 33" long. To size the stretchers, use that same number minus the 3 ⁄ 4 " dado allowance. Calculate upper cabinet sizes the same way. DIY or Let Us Draw For You. Draw your floor plan with our easy-to-use floor plan and home design app. Or let us draw for you: Just upload a blueprint or sketch and place your order.