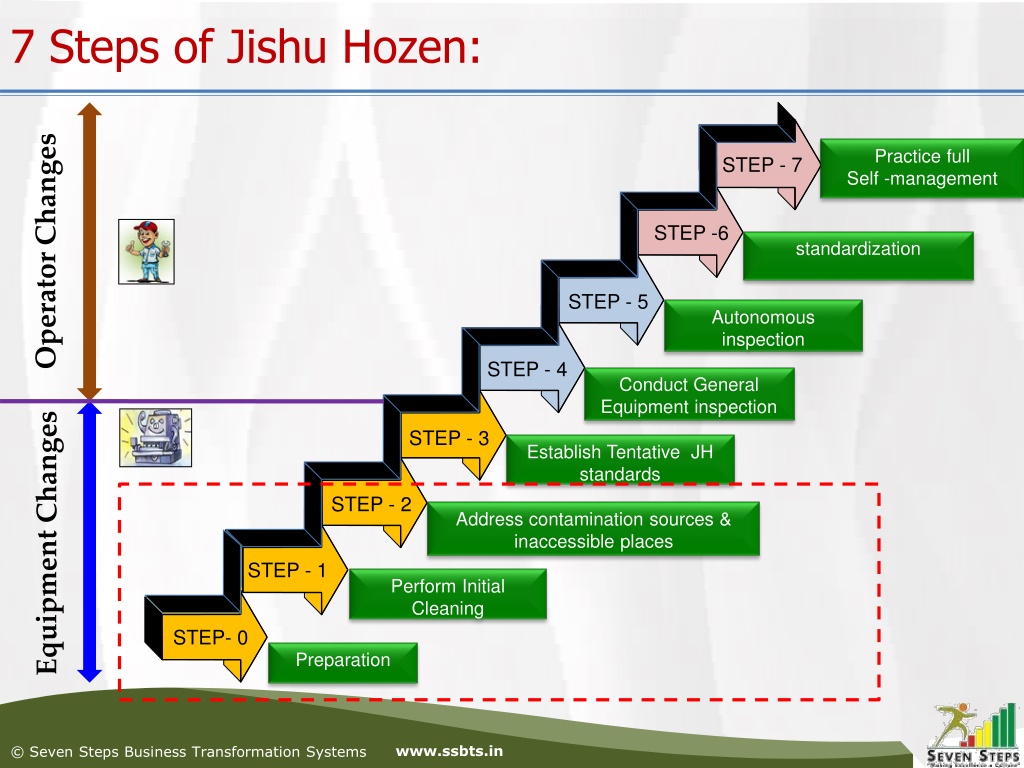

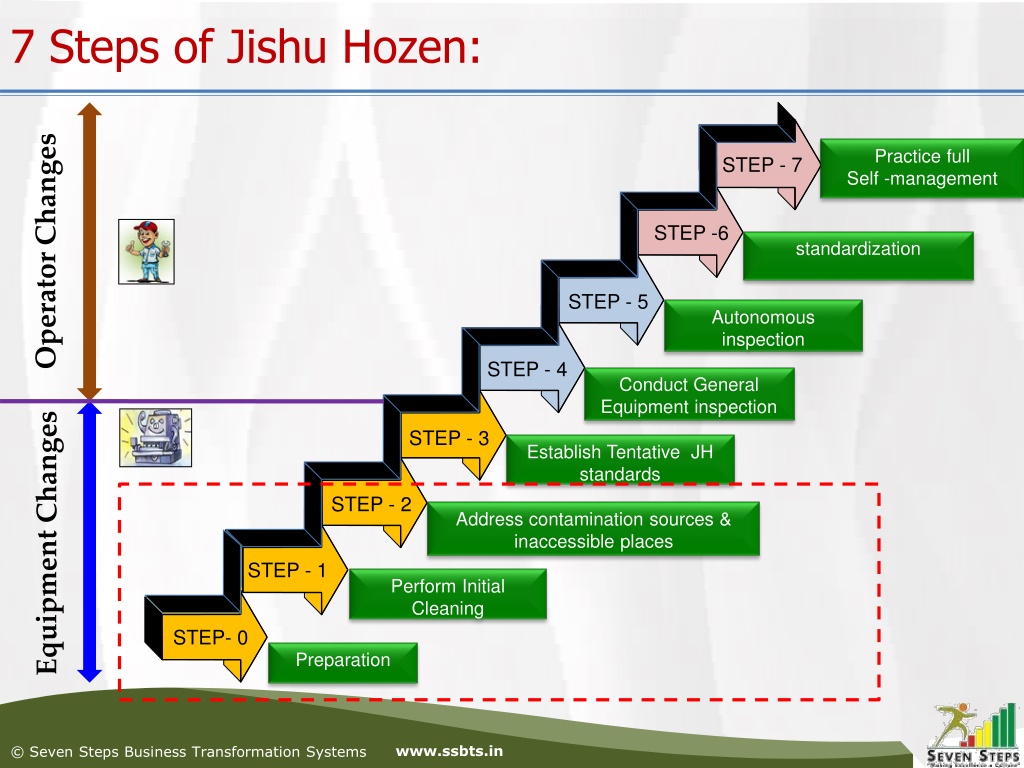

7 Steps of Jishu Hozen (Autonomous Maintenance) Pillar in TPM 14 Comments What is Jishu Hozen (Autonomous Maintenance)? → The Jishu Hozen is a Japanese word that means autonomous maintenance. → Autonomous Maintenance is a well-defined method for maintaining the machine by the operator rather than the maintenance person. "Jishu" loosely translated, means - independence, autonomy. "Hozen" when translated to English means - preservation, integrity or conservation. Jishu Hozen is one of the eight pillars of Total Productive Maintenance, the other seven being: Focussed Improvement Planned Maintenance Training & Education Early Management Quality Maintenance

TPM 7 Steps of Autonomous Maintenance (Jishu Hozen) Poster (3page PDF document) Flevy

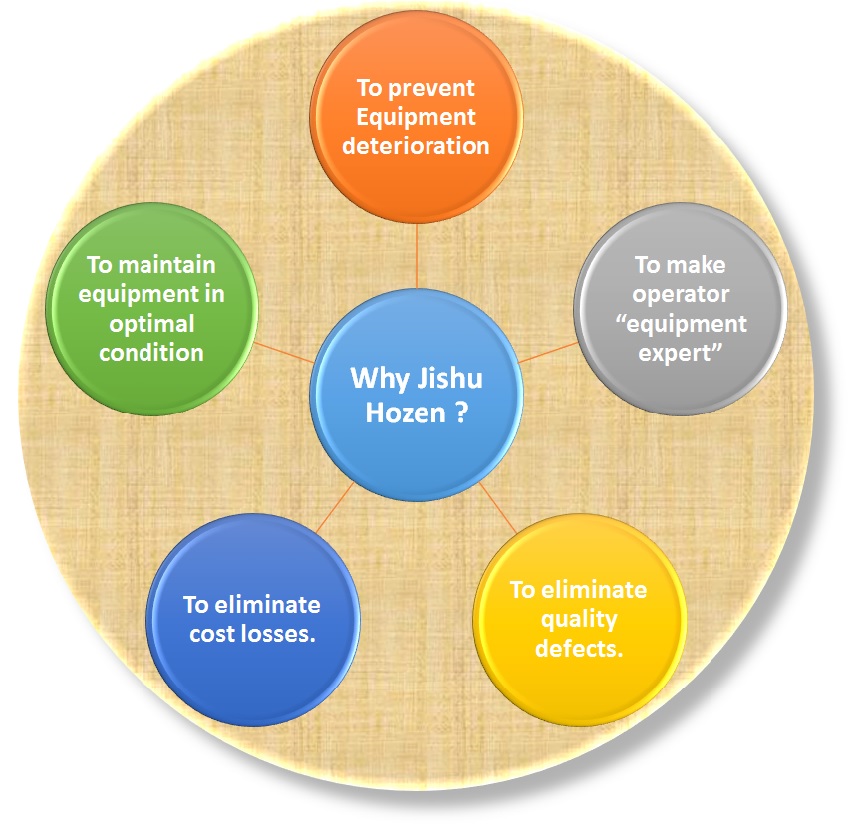

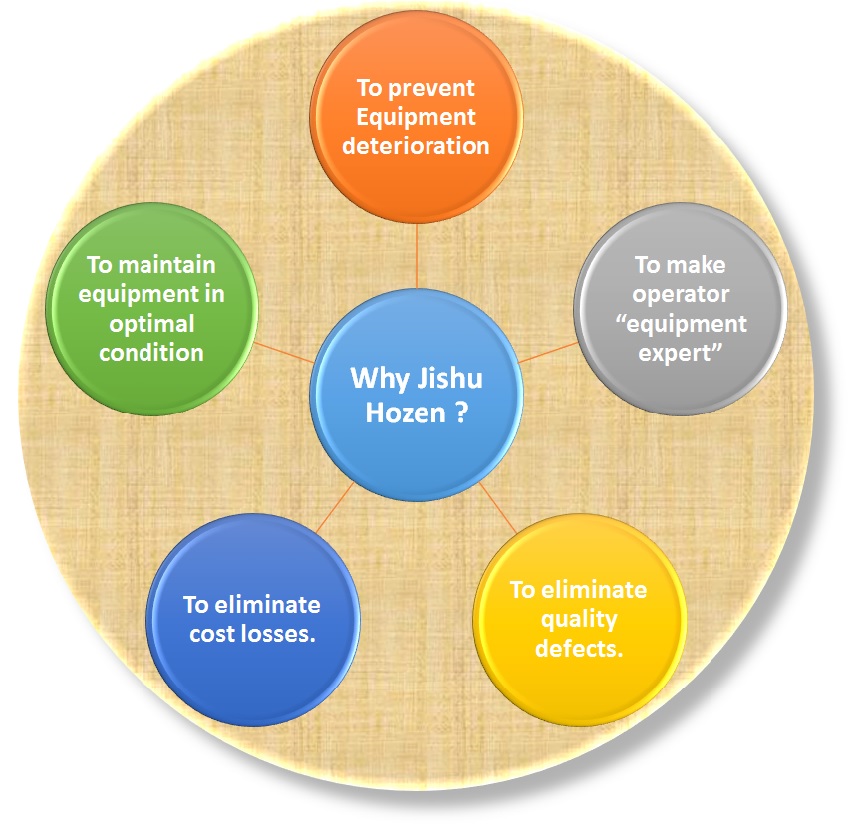

Leadership Commitment and Support Jishu Hozen Pillar in Total Productive Maintenance (TPM) Role of Jishu Hozen Pillar in TPM Importance of Jishu Hozen Pillar for TPM success Best practices for integrating Jishu Hozen Pillar with other TPM pillars Implementing Jishu Hozen Pillar Steps involved in implementing Jishu Hozen Pillar In this presentation, we will explore the importance and steps involved in Jishu Hozen. Overview of Jishu Hozen. Jishu Hozen, meaning "autonomous maintenance," aims to empower frontline operators to take responsibility for the upkeep and improvement of their equipment. It focuses on preventive maintenance, maximizing equipment performance, and. It is also called by other names such as Jishu Hozen. Autonomous Maintenance is a concept that emphasizes the involvement of operators/frontline team members to maintain their machines themselves with the support of the Maintenance department & completely own their equipment for ease of operation & Maintenance activity. The term 'Autonomous Maintenance' refers to the concept in industry where the operators of machines and equipment are trained to perform some basic maintenance tasks on their machines to reduce chances of breakdown. Autonomous Maintenance is actually a sub-concept of a bigger concept in maintenance called Total Productive Maintenance (TPM).

PPT JH Pillar training up to step 02 PowerPoint Presentation, free download ID11532593

Step 2: Remedy for contamination sources and hard-to-access areas ; This is the second step of Jishu Hozen. This step involves detecting sources of dust and stains, preventing scattering of dust, and improving hard-to-access areas for cleaning, oiling, retightening, or inspection, and shortening time for these activities. In this Tutorial we discussed about all 7 Steps of Jishu Hozen. we explained that Kill Machine Abnormalities (FUGUAI) through 5G | 3G | GEMBA | JH LEAN | TPM Lean Seekho 929 views 1 year. The Autonomous Maintenance or Jishu Hozen audit system assesses the progress made by production teams toward achieving the company's TPM goals. The Autonomous Maintenance audit step-by-step checklists are based on the TPM Excellence Framework. The AM audit checklists are especially useful for companies who want to kick-start the AM implementation process and are not quite sure how to define. PM & Jishu-Hozen, first step 36 Sumarizing AI / IoT sharing in PM & Jishu-Hozen 37 VI. Training of Jishu-Hozen. 39 Teach and training of basic repair & maintenance. 39 a) Tighten bolt properly. 39 The accident reporting. 39 Training of tightening bolt properly. 41 Aim of the training and target 41 Target persons of training and preconditions 41

Concepts of Business Excellence Concepts of Total Productive Maintenance Topic 6 Steps

159-slide PowerPoint presentation (PPTX) on TPM: Autonomous Maintenance (Jishu Hozen) with a supplemental Zip archive file document. Autonomous Maintenance (Jishu Hozen) is one of the most important building blocks in any Total Productive Maintenance (TPM) program. Autonomous Maintenance refers to TPM activities that involve operators in maintaining their own equipment, independent of the. TPM is a step by step process and it involves all the employees for a factory for a common goal and that is to minimize the losses.. Jishu-Hozen (JH) or Autonomous Maintenance; This pillar is responsible for autonomous maintenance of the machines and equipment used for work. It is considered that there is a mother and child like relationship.

12 Steps of TPM Implementation → 12 Steps for Implementation TPM are mentioned below. Declaration by top management to introduce TPM Education and training about the TPM campaign Formation of the committee for TPM promotion in the organization The setting of basic TPM principles and targets Preparation of a master plan for implementing TPM Autonomous Maintenance (Jishu Hozen) is one of the most important building blocks in any Total Productive Maintenance (TPM) program. Autonomous Maintenance refers to TPM activities that involve operators in maintaining their own equipment, independent of the maintenance department.

7 Steps of JH ! Jishu Hozen !! TPM Pillar !!! ASK Mechnology !!!! YouTube

Step 1:Initial-phase cleaning 2 :Efu / Tag Step2:Countermeasures for the source of problems Step3: Establishment of tentative standards for "Jishu-Hozen" Step 4: General [Overall] inspection Step 5: Autonomous inspection Step6:Standardization ("Jishu-Hozen") Step 7:Thorough implementation of autonomous Share Slide Share "Jishu-Hozen "Activities The operator also learns 7 steps of Jishu-Hozen 1. that helps to up-keep the performance level of the machine and achieving the target of zero down time.