Here is a tried and tested sample circuit of a Li-Ion battery charger that can be used to charge any 3.7V Li-Ion battery using a 5VDC (USB, Solar Panel…) power supply. At the heart of the circuit is one microchip MCP73831, available in SOT-23-5 package. MCP73831 is a highly advanced linear charge management controller for use in space-limited. 51 thoughts on " Lithium-Ion Battery Circuitry Is Simple ". I wish there were a charger circuit as readily available as TP4056 boards that allowed 4.0v termination voltage, I'd replace.

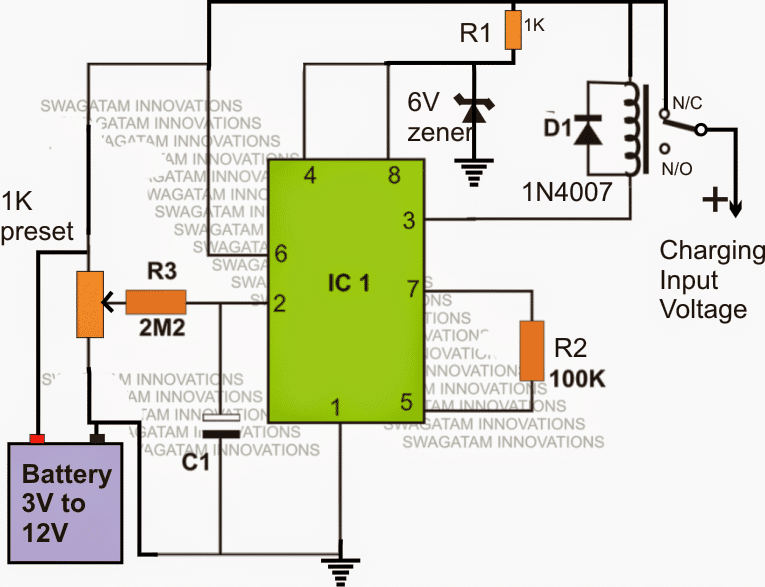

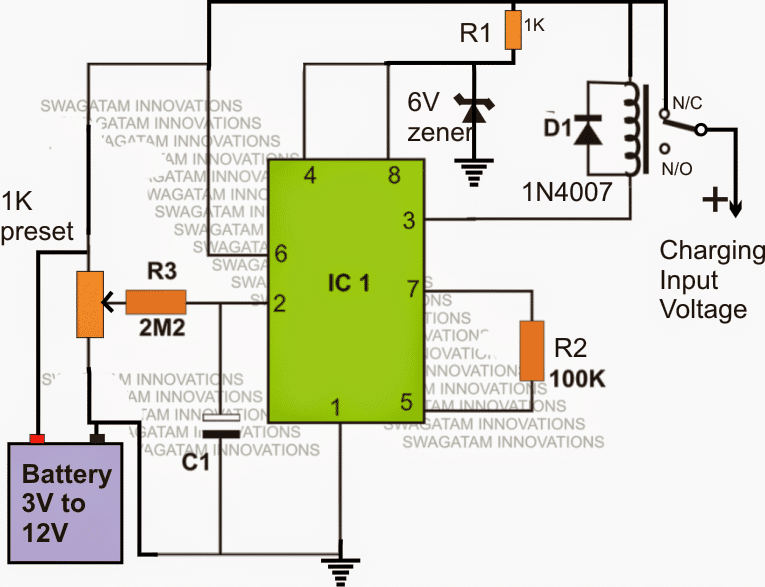

LiIon Battery Charger Using IC 555 Homemade Circuit Projects

Charging the battery forces the ions to move back across the electrolyte and embed themselves in the negative electrode ready for the next discharge cycle (Figure 1). Figure 1: In a Li-ion battery, lithium ions move from one intercalation compound to another while electrons flow around the circuit to power the load. 4 Simple Li-Ion Battery Charger Circuits - Using LM317, NE555, LM324. The following post explains a four simple yet a safe way of charging a Li-ion battery using ordinary ICs like LM317 and NE555 which can be easily constructed at home by any new hobbyist. Although Li-Ion batteries are vulnerable devices, these can be charged through simpler. Calibration: Step 1: Disconnect the battery to be charged. Step 2: Connect the DC power supply to the input. Step 3: Adjust the variable resistor till you get full charge voltage at the output terminal. (For 3.7V Li-ion output voltage will be 4.2V but here we will set it to 4.1V to increase the battery life). Main features of this Li-ion / Li-Po battery charger circuit. How to charge a 3.7V Li-ion / Li-Po cell correctly. Circuit diagram of Li-ion / Li-Po battery charger.. 149 thoughts on " Arduino Lithium-ion Battery Charger " Rick says: December 7, 2019 at 7:22 am. Really good Instructable. Thanks!

LiPo Battery Charger Circuit

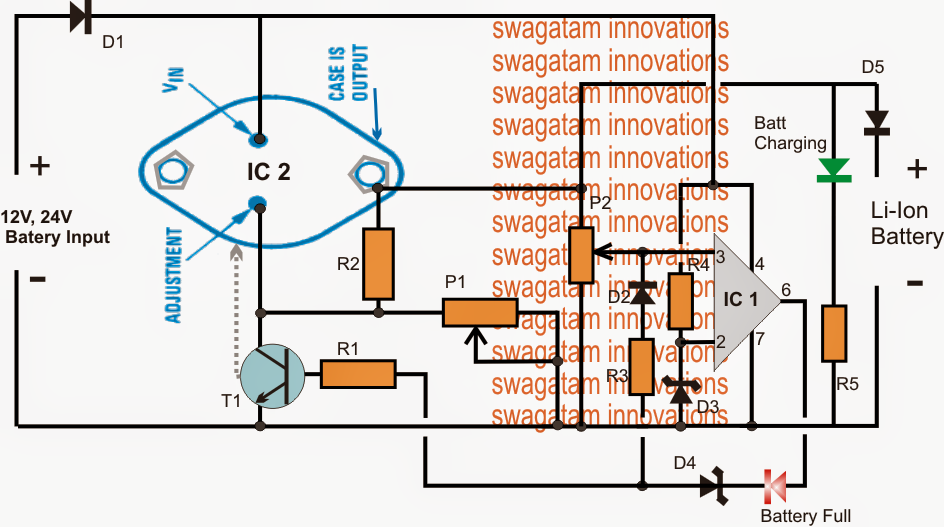

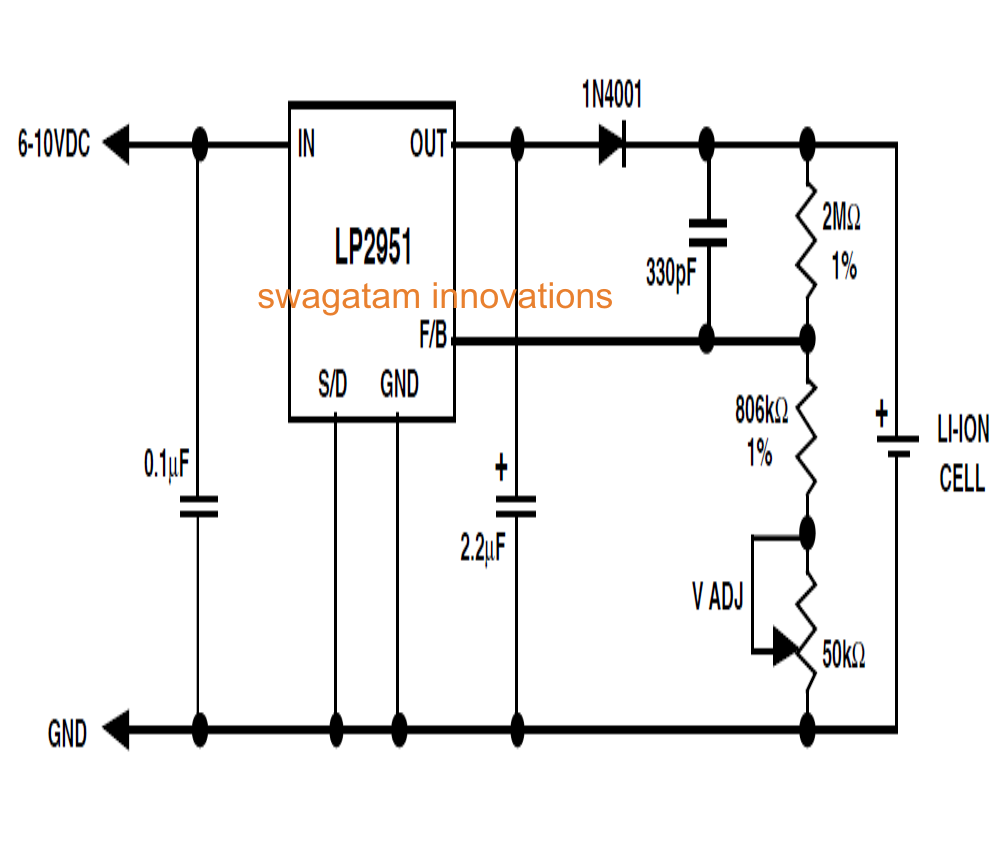

The final lithium ion battery charger circuit is the most advanced, and takes the advantages of the prior method, and removes the main con's. There are battery charging IC's made by Texas Instruments, Analog Devices, and Maxim that have what they call "Power Path" management. Step 8: Trial Run. Insert a discharged lithium-ion battery inside the charger, connect a 12 V DC input or a USB input. Charger should flash RED led indicating charging is in progress. After a while, once battery gets charged, charger should flash BLUE led. Unless a Li-ion battery is charged very slowly (usually 0.15 C or even less), terminating the charge based on reaching a voltage of 4.2 V/cell will only charge the battery to a maximum of 0.7C. Some batteries may only reach 0.4C. Charging Li batteries at less than 4.2 V/cell is possible but also not recommended. The battery charger circuit is designed for 7.4V lithium battery pack (two 18650 in Series) which I commonly use in most robotics project but the circuit can be easily modified to fit in lower or slightly higher battery Packs like to build 3.7 lithium battery charger or 12v lithium ion battery Charger. As you might know there are ready made.

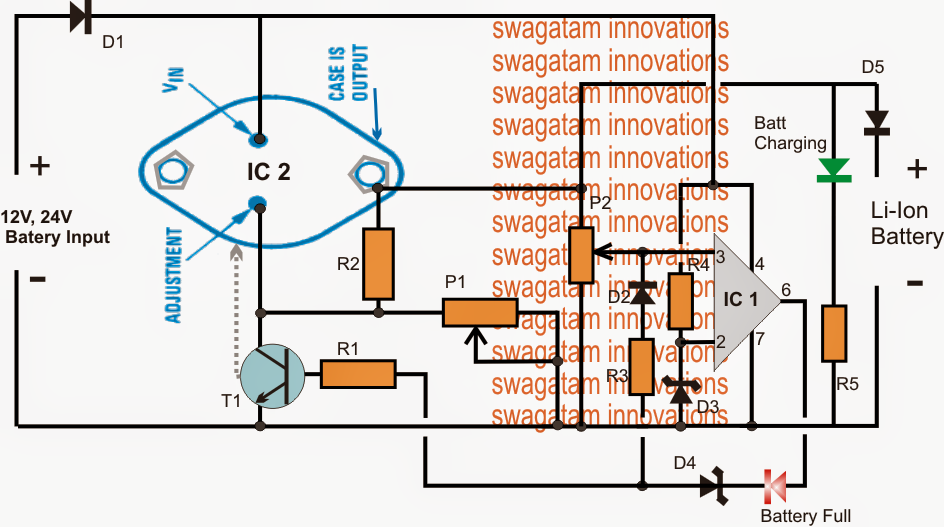

High Current 12V, 24V LiIon Battery Charger Circuit

Understanding the basics of charging and discharging circuits for lithium-ion battery cells is key to proper contacting system design as well as successful manufacturing and testing. Figure 2: Typical application circuit for the MCP73827 Another easy way to charge a lithium battery is to use Linear Technology's LT3650, a DC-DC converter with integrated lithium-ion battery charger intelligence. A designer adds a few passive components to implement a complete lithium battery charging solution.

The TP4056 is a low-cost Lithium Ion battery charger controller IC. It supports a constant current - constant voltage charging mechanism for s single cell Li-Ion Battery. It is available in 8-pin SOP package and requires very minimum external components in order to build a Lithium Ion battery charger circuit. The word 'Ion' existing with the battery's name merely means that Lithium must never be encountered in its metallic form in the battery. The electrolyte collects lithium ions (Li+) on the graphite anode throughout the charging process.. Figure 4 depicts a Li-Ion charger circuit in accordance with the National Semiconductor IC LM 3622.

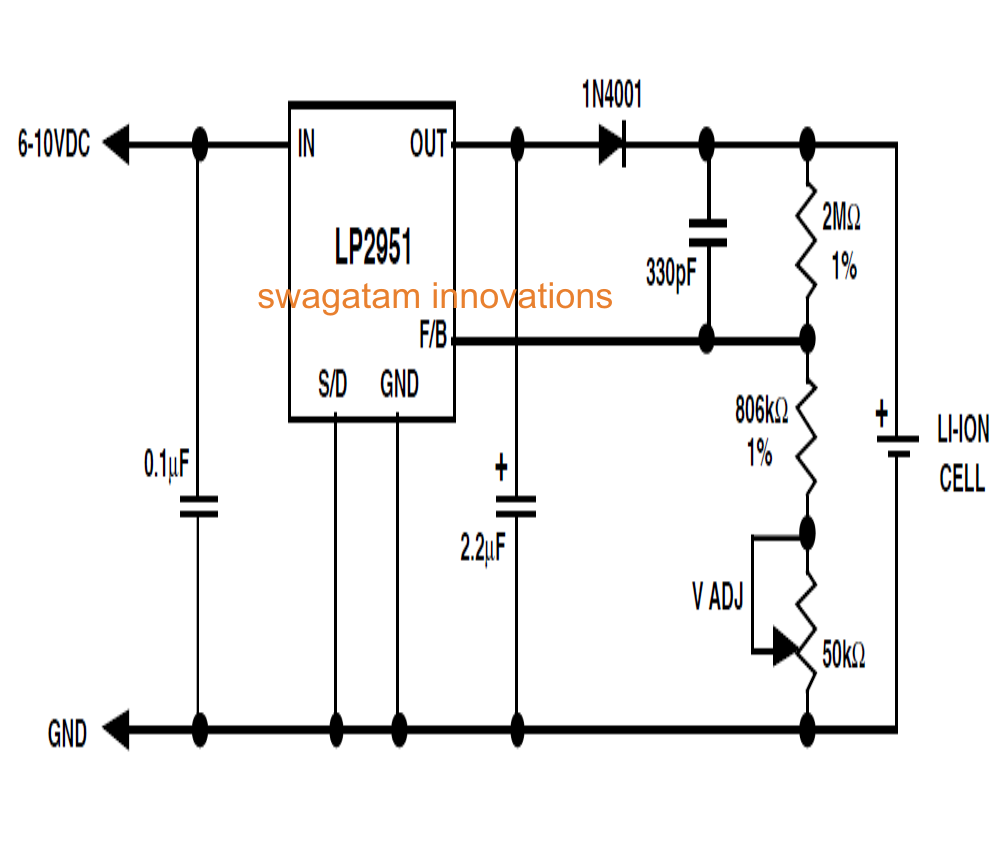

LiIon Battery Charger Circuit Using IC LP2951 Circuit Diagram Centre

In this project we will build a Two Stage Battery charger (CC and CV) that could be used as to charge Lithium ion or lithium polymer batters. The battery charger circuit is designed for 7.4V lithium battery pack (two 18650 in Series) which I commonly use in most robotics project but the circuit can be easily modified to fit in lower or slightly. Materials needed. A microchip MCP73831, resistors, a 5VDC power source. Design Principle. You can use a standard 3.7-volt lithium-ion battery charger to charge a 3.7 V Li-Ion Cell up to 4.2V. The charger performs its function by increasing voltage from 0.25 V to 4.0 V in an hour at a 1 amp constant current charging rate.