What is PLC Control Panel Wiring? PLC Control Panel Wiring refers to the process of connecting various electrical components, such as switches, relays, and sensors, to a programmable logic controller (PLC) in order to control and monitor different machinery or processes. Electrical wiring diagrams of a PLC panel In an industrial setting a PLC is not simply "plugged into a wall socket". The electrical design for each machine must include at least the following components. Transformers - to step down AC supply voltages to lower levels

Ban genius sunset plc layout

by Viral Nagda In this article, you will learn the wiring in a PLC control panel and the basic electrical design of a PLC system cabinet. Wiring in a PLC control panel is a hectic job and requires a good understanding of PLC standards as well as electrical standards. How to Read a PLC Wiring Diagram (Control Panel Wiring Diagram) - Upmation How to Read a PLC Wiring Diagram? In this article, you'll learn how to read, understand and use a PLC wiring diagram. Reading a PLC Wiring Diagram is one of the must-to-learn skills for every automation and electrical engineer. A PLC panel is simply an electrical control panel consisting of electrical components which use electric power to control a variety of mechanical functions of industrial machinery or equipment. In order for industrial machinery and equipment to accomplish their various process goals, they require user-defined functions and well-organized control. Vladimir Romanov Electrical panel wiring diagrams are used to outline each device, as well as the connection between the devices found within an electrical panel. As electrical panels are what will contain control systems, panel wiring diagrams are commonly encountered by PLC technicians and engineers.

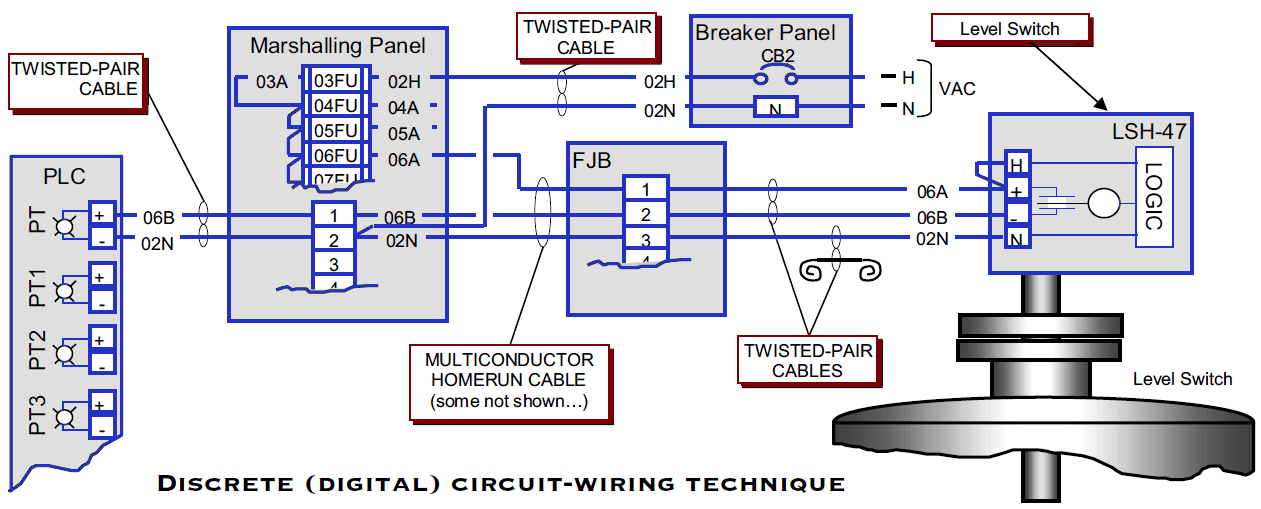

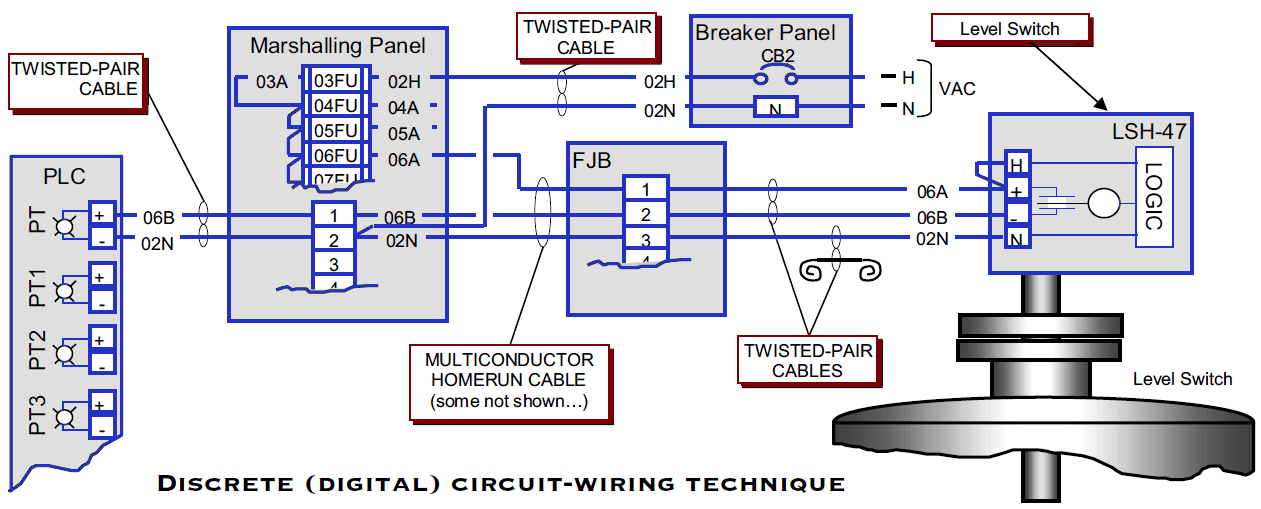

PLC Wiring Diagrams PLC Digital Signals Wiring Techniques

How to PLC Control Panel wiring Power Process 337 subscribers Subscribe No views 1 minute ago #PLCControlPanel #IndustrialAutomation #ElectricalEngineering In this comprehensive video. Join us here, get awesome perks, and support us, all at once:https://www.youtube.com/c/upmation/joinRead the full blog post at https://upmation.com/plc-w. It is a 2-door control panel on the front of which we have some switches that are connected to the PLC inputs and outputs. We are going to look at these switches and try and figure out the. Wiring diagram. Now you maybe be curious how you should know which input on the PLC you should connect the Emergency-Stop to. Well, this is simply done based on the wiring diagram. In a later article, we will get into the details of the wiring diagram and show you how simple it is to read and carry out the control panel wiring.

Reliance SCADA in Istanbul

The following considerations will facilitate an orderly installation of a PLC: PLC I/O module installation Wiring considerations Recommended wiring procedures Wire size Wire and terminal labeling Wire bundling Special I/O connection precautions Connecting leaky inputs Suppression of inductive loads Fusing outputs Shielding I/O module installation Control Panels compliant with IEC Standards and European Directives 6 Reference Manual, 10/2017, A5E38284819002A/RS-AB/002 Authors Martin Berger Staatlich geprüfter Techniker (state-certified technician) Application consulting and business development for control panel engineering and low - voltage controls and distribution

location wiring diagrams also evolved into the relay logic being shown in a ladder fashion. The control power hot wire would be the left rail, with the control power neutral as the right rail. The various relay contacts, pushbuttons, selector switches, limit switches, relay coils, motor starter coils, solenoid Now we have to understand that -v (0V) We need to create a potential difference of +V (24V) across these input terminals. Then only this PLC will recognize that there is some input. For example, if i connect this V over here (IN ). And then i am going to simulate that. You will see this is ON.

PLC wiring diagram. Download Scientific Diagram

Wiring Diagrams of PLC and DCS The below list shows the basic types of wiring connections available for DI, DO, AI, and AO Signals: Digital Input (DI) Signals Single-wire Connection Two-wire connection Two-wire connection with Line Monitoring DI with Relay - Wet Contact DI with Relay - Dry Contact Now we have to understand that -v (0V) We need to create a potential difference of +V (24V) across these input terminals. Then only this PLC will recognize that there is some input. For example, if i connect this V over here (IN ). And then i am going to simulate that. You will see this is ON.