- Types of Blades - Discharge Options - Integration into a Production Line - Common Manufacturers Functions of a Sigma Arm Mixer The operations of a sigma arm mixer begin with the materials being loaded into the bowl through the top of the container. The sigma blade mixer is the most commonly used type of double arm kneader mixer, and is best suited for all round use. Sigma Blade Mixer The sigma blade profile is shown in figure 1. In mixers handling very viscous materials, it is necessary to promote both lateral and transverse motion of the material.

Double Sigma Arm Spiral Mixer Shaffer Mixers & Bakery Equipment

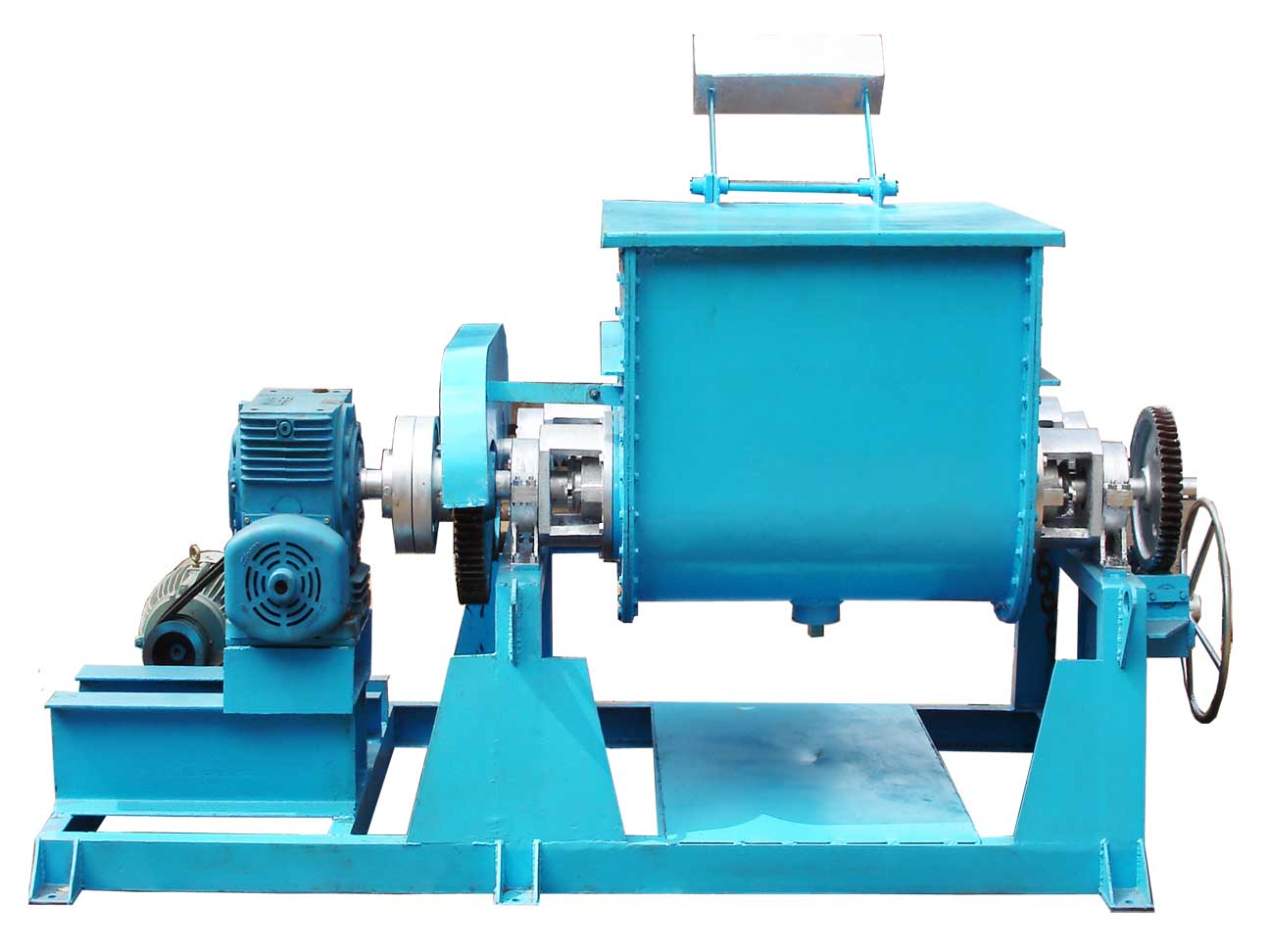

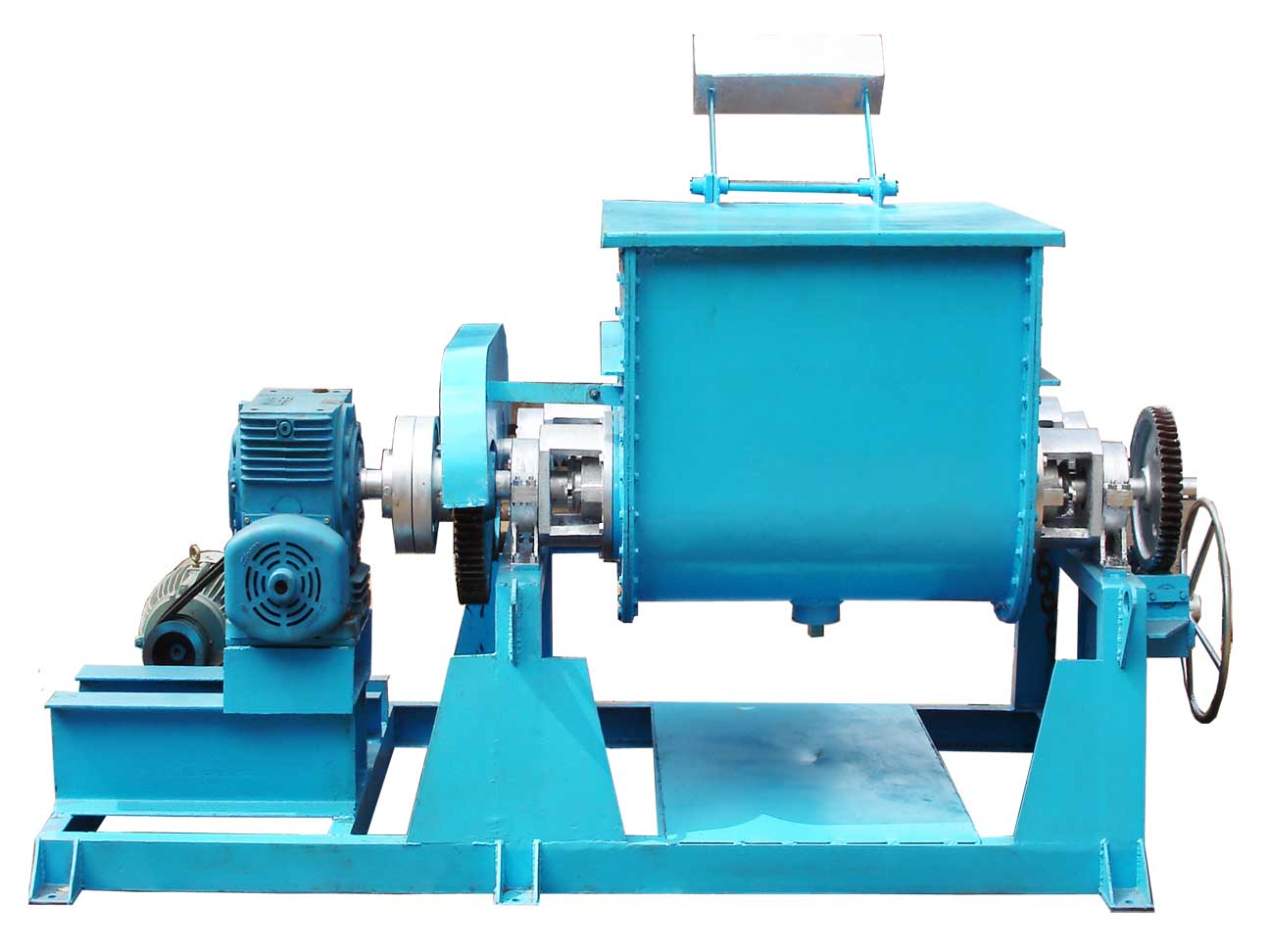

This type of mixer is usually equipped with a jacket to help with temperature control when cooking or cooling products. After the product is measured it is dumped into the top of the sigma arm mixer. Sigma arm mixers are designed to rotate the mixer body to help with product removal. Sigma mixers work well with pastes and powders. This type of mixer is usually equipped with a jacket to help with temperature control when cooking or cooling products. After the product is measured it is dumped into the top of the sigma arm mixer. Sigma arm mixers are designed to rotate the mixer body to help with product removal. Sigma mixers work well with pastes and powders. Double Sigma Arm Mixers incorporate extra strong shaft gears, which are hardened and ground, and have the highest possible rating from the AGMA. Uniquely designed shaft seals are sanitary and easy to remove. Other Standard Features • Unibody design and construction for strength and stability, regardless of the load size or dough type. This type of sigma mixer has two bladed shafts next to each other that rotate in different directions at different speeds. This enables them to rotate pastes, doughs and powders, thoroughly mixing the materials. Some double sigma arm mixer bowls are manual tilt, which requires an operator to turn a wheel to tip the bowl, while others are automatic.

Sigma Mixer Working Principle Function And Application For Industrial Use

This type of mixer is usually equipped with a jacket to help with temperature control when cooking or cooling products. After the product is measured it is dumped into the top of the sigma arm mixer. Sigma arm mixers are designed to rotate the mixer body to help with product removal. Sigma mixers work well with pastes and powders. The sigma mixer is one of the most popular used for mixing and kneading high viscosity materials. It belongs to the family of double arm kneader mixers. Double Arm Kneader Mixers All double arm kneader mixers are equipped with two mixing blades placed in a W-shaped horizontal trough. With over 50 years of experience in mixing innovation, AMF's Specialty Sigma Arm Mixer offers maximum flexibility and unmatched reliability for a variety of dough types. Offered as part of a complete dough system solution, the Sigma Arm Mixer is seamlessly integrated with AMF's dough chunker, dough elevator, and sanitary dough conveyors. Double Sigma Arm Mixers incorporate extra strong shaft gears, which are hardened and ground, and have the highest possible rating from the AGMA. Uniquely designed shaft seals are sanitary and easy to remove. Other Standard Features Unibody design and constftlction for strength and stability, regardless of the load size or dough type.

Sigma Mixer in Ahmedabad, सिग्मा मिक्सर, अहमदाबाद, Gujarat, India

Peerless Single Sigma arm Mixers are ideal for rotary molded and laminated or sheeted cookies, crackers, biscuits, corn tortillas, buttermilk biscuits, energy bars, pet foods and cream fillings. Mixer Model Dough Lbs. Capacity kGs. Note: SD3 SD4 Application and introduction Sigma mixer is an widely used mixing machine ,with strong mixing blade and motor ,mainly for high viscous materials and slurries, It with special Z blade ,and a U shape chamber with cover , Two blade rotating with different speed ,one is slow and one is quick .two. Contact Now Vacuum Sigma Blade Mixer with Extruder

A sigma blade mixer typically consists of two sigma-shaped blades that are mounted on parallel shafts. The blades have a curved "S" shape and are oriented diagonally to each other. They rotate in opposite directions, generating a kneading and shearing action. Mixing Principle All double arm kneader also called Z arm Sigma mixers are competent of with two mixing blades situated in a W-shaped horizontal furrow. A variety of blade shape have evolved, every of which is best suitable for a scrupulous type of compliance. The frequently use blade types are the spiral blade, masticator blade sigma blade, nabbed blade, and shredder blade.

Double Arm Sigma Mixer

The sigma blade mixer is the most commonly used type of double arm kneader mixer, and is best suited for all round use. Sigma Blade Mixer In mixers handling very viscous materials, it is necessary to promote both lateral and transverse motion of the material. Sigma mixers operate at low tip speeds of 60 - 70 metres per minute. Mixing is accomplished at ambient temperature or under conditions of controlled temperatures, depending on the process requirements.