Single-phase induction motors have a copper or aluminum squirrel cage embedded in a cylinder of steel laminations, typical of polyphase induction motors. Permanent-Split Capacitor Motor One way to solve the single phase problem is to build a 2-phase motor, deriving 2-phase power from single phase. For the single phase motor, do the following: (1) Check the appearance of the motor. Check for burnt, damage to body or cooling fan or shaft. (2) Manually rotate motor shaft to examine bearing condition. Look out for smooth and free shaft rotation.

Types of Single Phase Induction Motors Applications

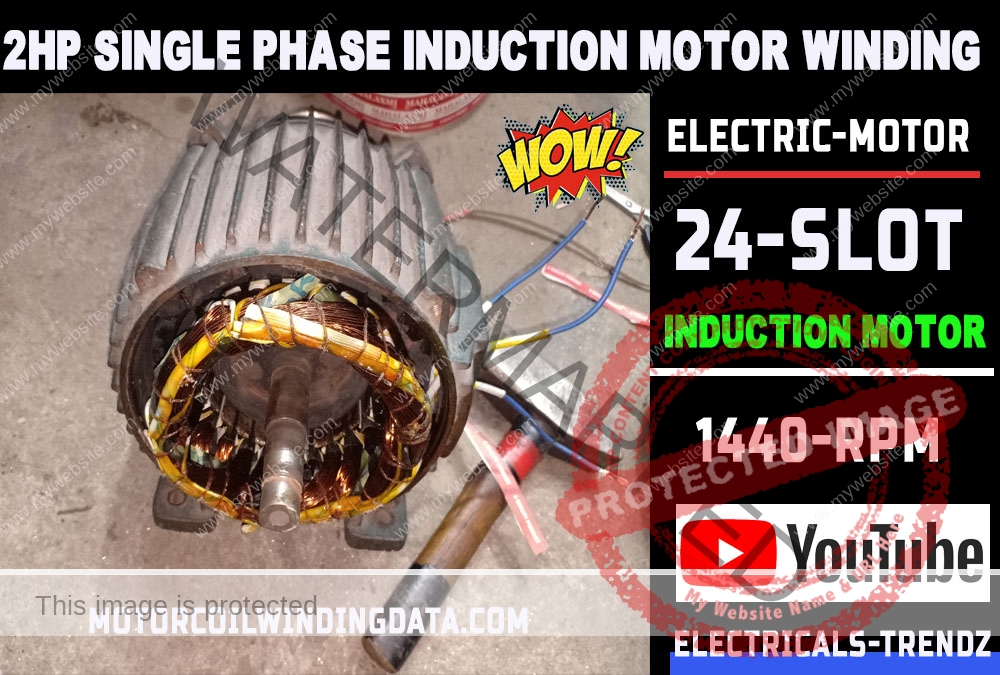

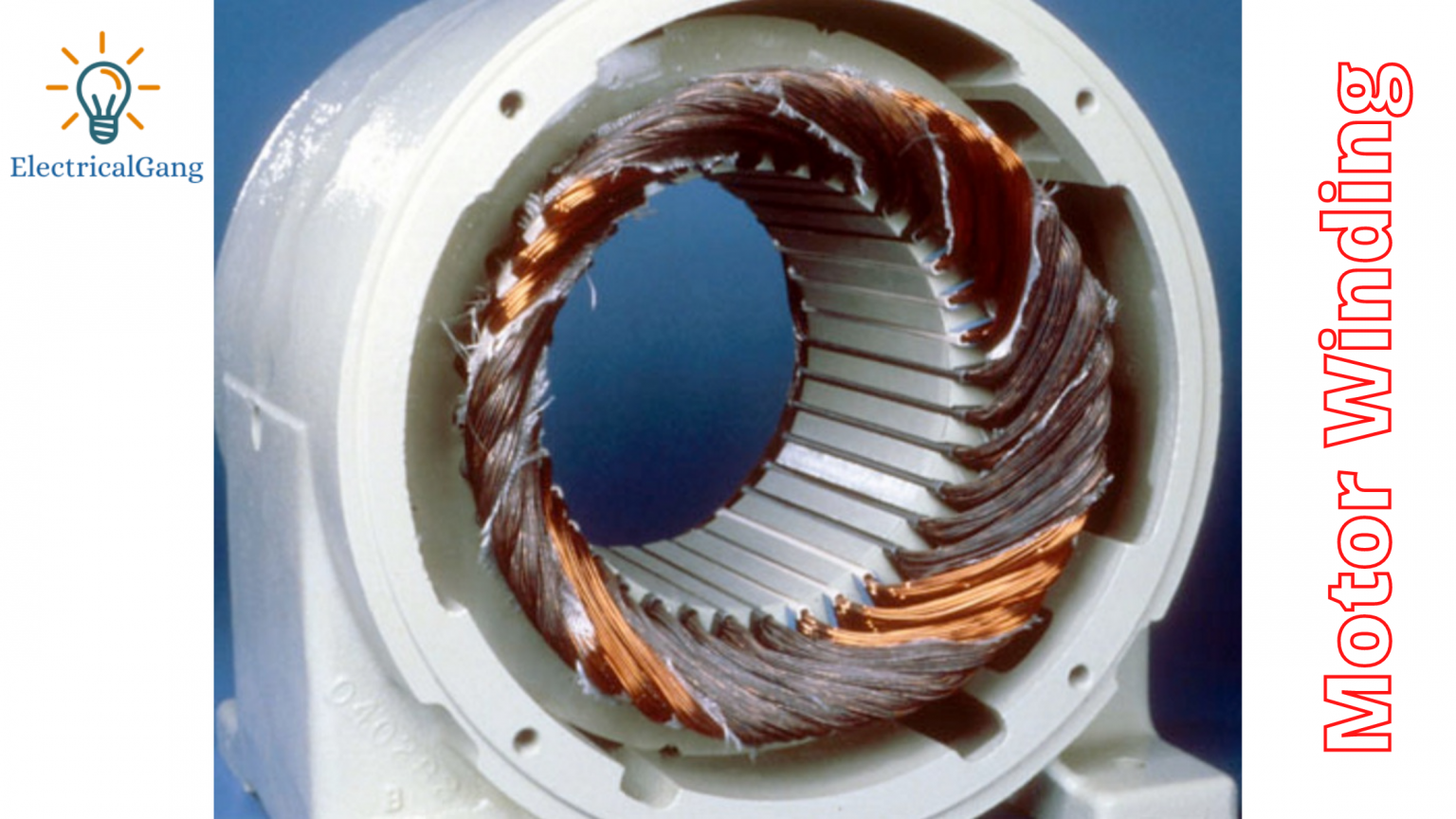

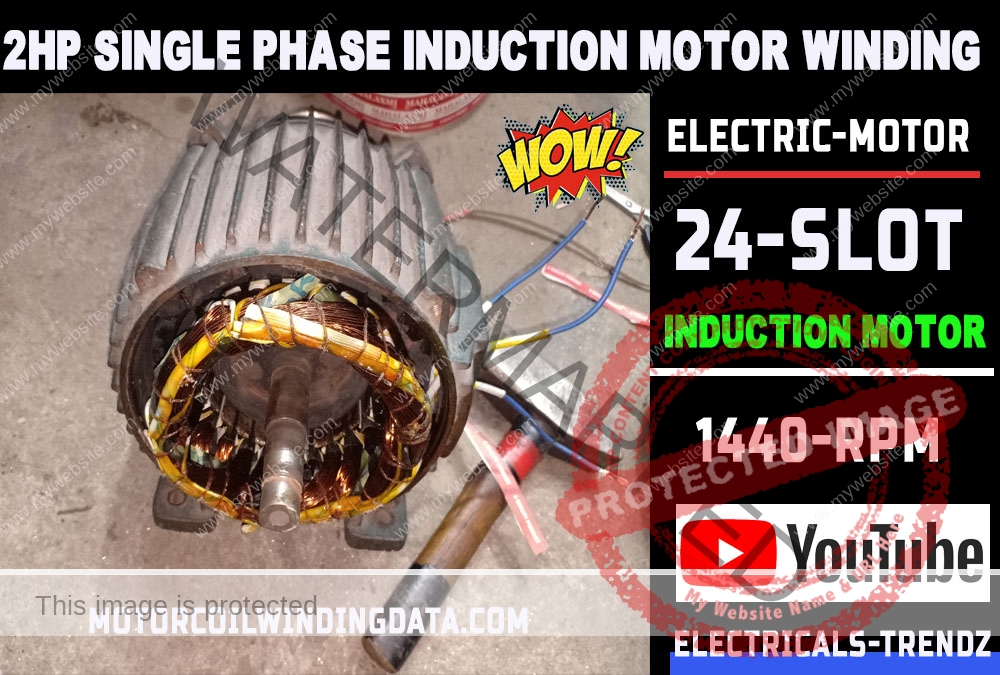

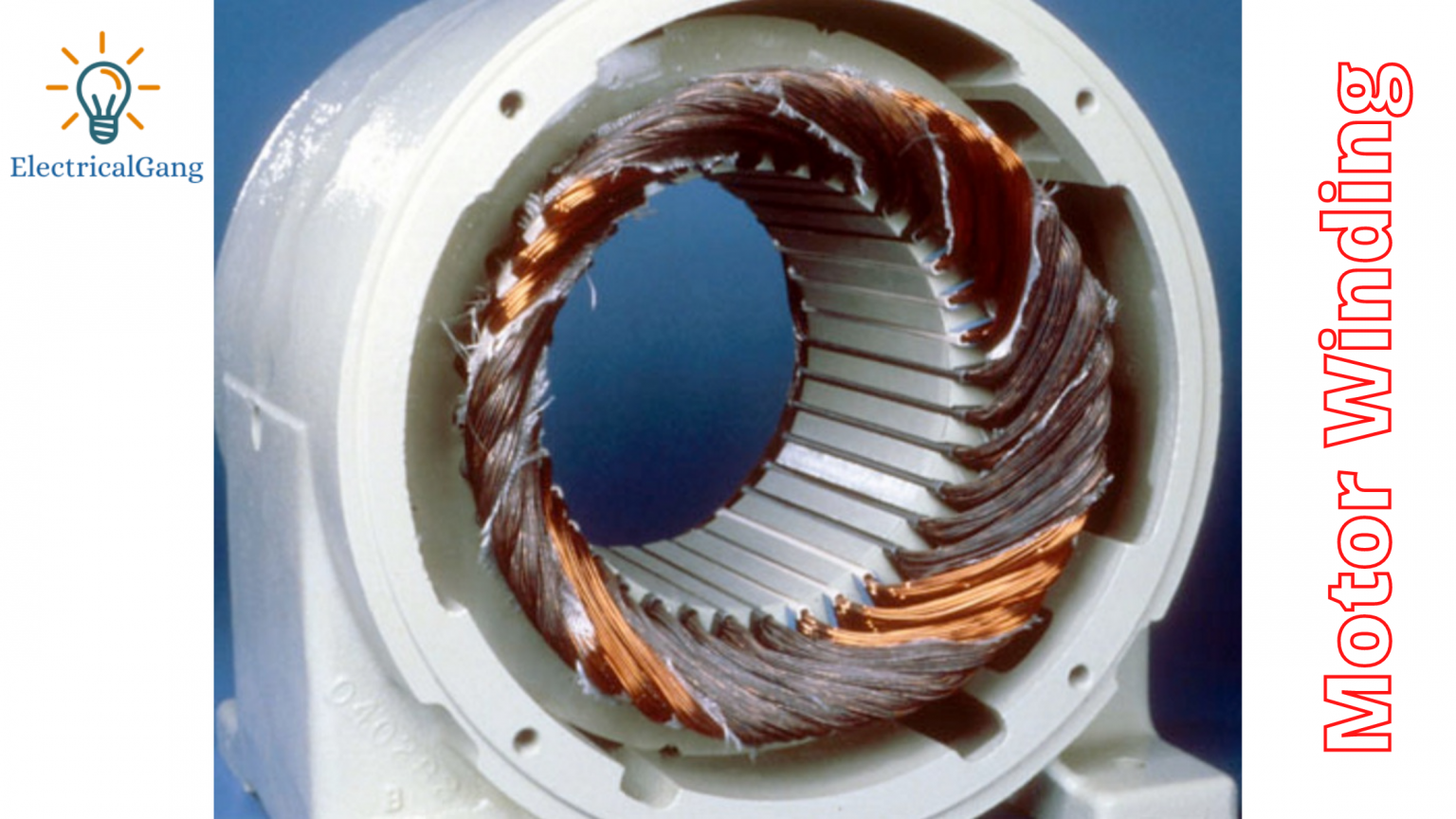

If you open the single-phase motor, you will find out that your motor has two types of winding of which one is made from a thick wire gauge and one thin. the thick wire gauge winding is the main winding and the thin wire gauge winding is the starting winding. In a single-phase induction motor, there are two winding are used in stator except in shaded-pole induction motor. Out of these two windings, one winding is the main winding and the second is auxiliary winding. The stator core is laminated to reduce the eddy current loss. The single-phase supply is given to the stator winding (main winding) GLOSSARY OF SINGLE-PHASE MOTOR TERMS centrifugal switch--a switch used to disconnect the start windings in a split-phase motor after the motor has accelerated to approximately 75% of rated speed compensating winding--a winding used in universal motors to counteract the inductive reactance in the armature windings Permanent-Split Capacitor Motor. One way to solve the single phase problem is to build a 2-phase motor, deriving 2-phase power from single phase. This requires a motor with two windings spaced apart 90 o electrical, fed with two phases of current displaced 90 o in time. This is called a permanent-split capacitor motor in Figure below.

Rewinding 3 Phase Motor Enjoy the topquality electronics here Motor, Electric motor

Single Phase Motor Winding Diagram - Main Winding and Starting winding. In single phase induction motor we have two types of winding coils in stator. In which one is made from thick wire and 2nd is made from the thin wire. For example one winding made from 21 SWG (Standard Wire Gauge) and 2nd is made from 26 SWG. often. The single-phase AC induction motor best fits this description. As the name suggests, this type of motor has only one stator winding (main winding) and operates with a single-phase power supply. In all single-phase induction motors, the rotor is the squirrel cage type. The single-phase induction motor is not self-starting. When the motor. The rated current of the designed motor winding was 2.74 A for the main winding and 3.15 A for the auxiliary winding. The performance of the designed motor compared to the traditional single-phase. Hence, stator of a single phase motor has two windings: (i) Main winding and (ii) Starting winding (auxillary winding). These two windings are connected in parallel across a single phase supply and are spaced 90 electrical degrees apart. Phase difference of 90 degree can be achieved by connecting a capacitor in series with the starting winding.

1Hp Single Phase Induction Motor Winding Electric Motor Winding

A Repulsion Electric Motor is, by definition, a single-phase motor with a stator winding arranged for connection to the source of power and a rotor winding connected to a commutator. Brushes and commutators are short-circuited and placed so that the magnetic axis of the rotor winding is inclined to the magnetic axis of the stator winding. Testing a Single Phase AC Motor. There are four common failure modes for single phase AC motors. First, one of the windings can break, leading to an open circuit. Second, the insulation can fail, leading to a short circuit. Third, the motor can be overloaded for numerous reasons (which can also lead to the first failure).

1 Tricky solution: Measure the winding resistances. Auxiliary windings are often thinner and therefore have a higher resistance (even if it's just a little bit higher). Once you know which terminals are used for each of the two windings, you can connect them to the power supply and the capacitor as shown in the following picture: Abstract: Single-phase induction motors are widely used in industry and the domestic sector. Their production in the world reaches several million pieces. In this regard, the share of electric energy consumption, despite the fact that their unit power is 0.5-1.5 kW, is up to 10% of the total power consumption by AC motors.

What Is Motor Winding? Types of Motor Winding

The winding calculator allows you to find the optimum winding layout for your electric motor in a fast and convenient way. You can investigate three-phase integer-slot, fractional-slot and concentrated windings, both with single and double winding layers where appropriate. Single-phase Induction Motors A three phase motor may be run from a single phase power source. (Figure below) However, it will not self-start. It may be hand started in either direction, coming up to speed in a few seconds. It will only develop 2/3 of the 3-φ power rating because one winding is not used.