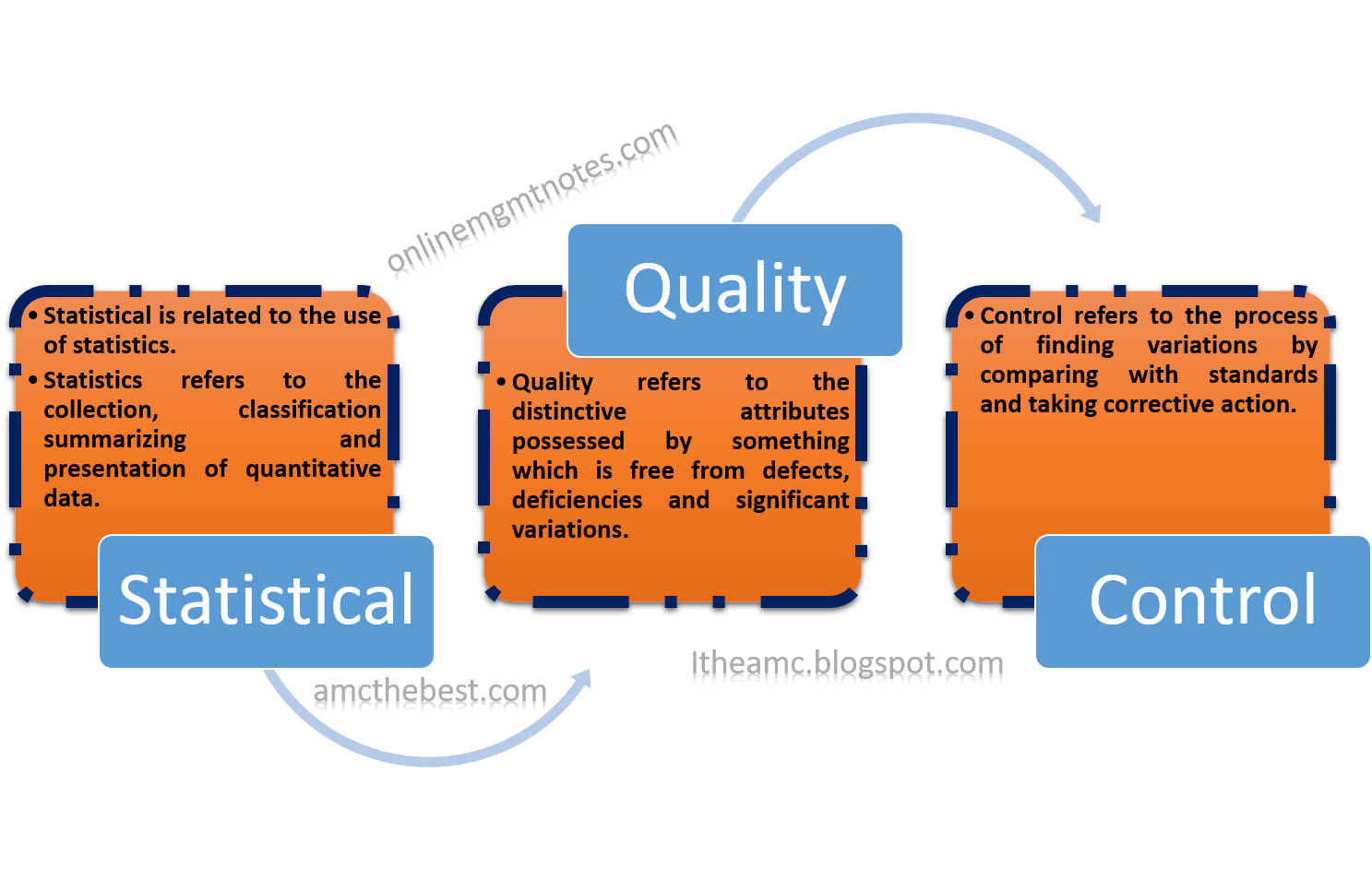

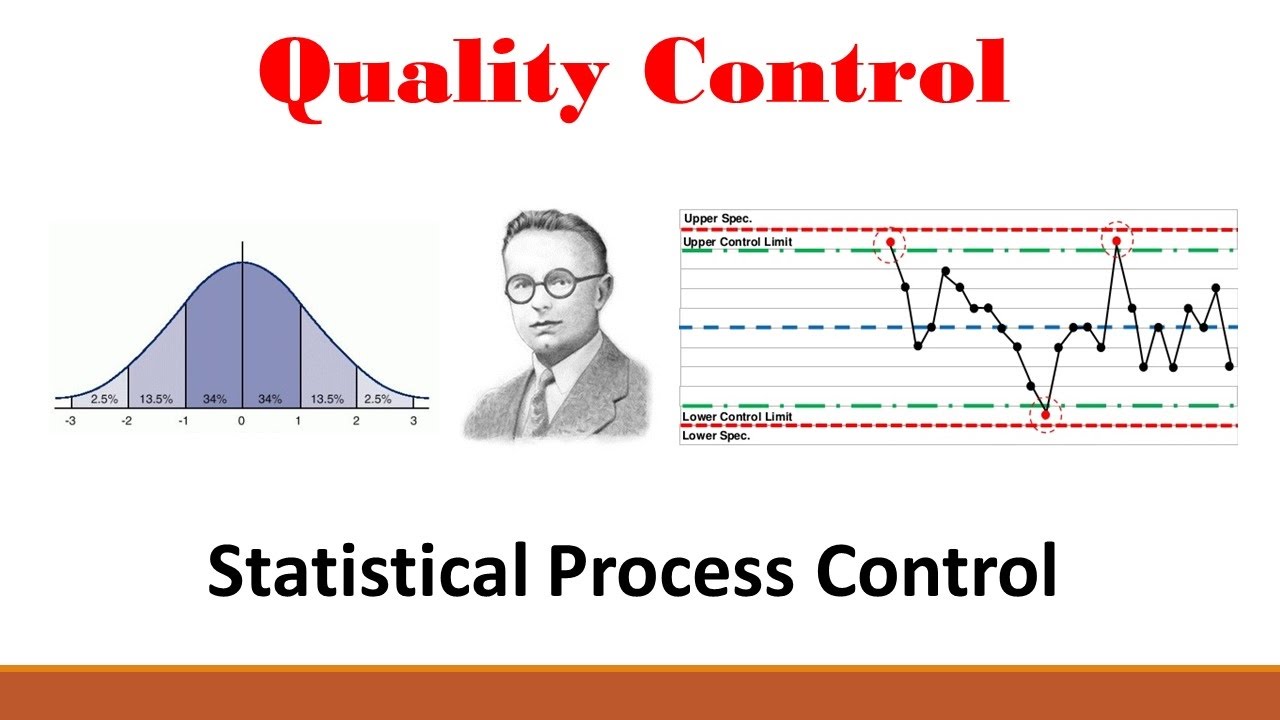

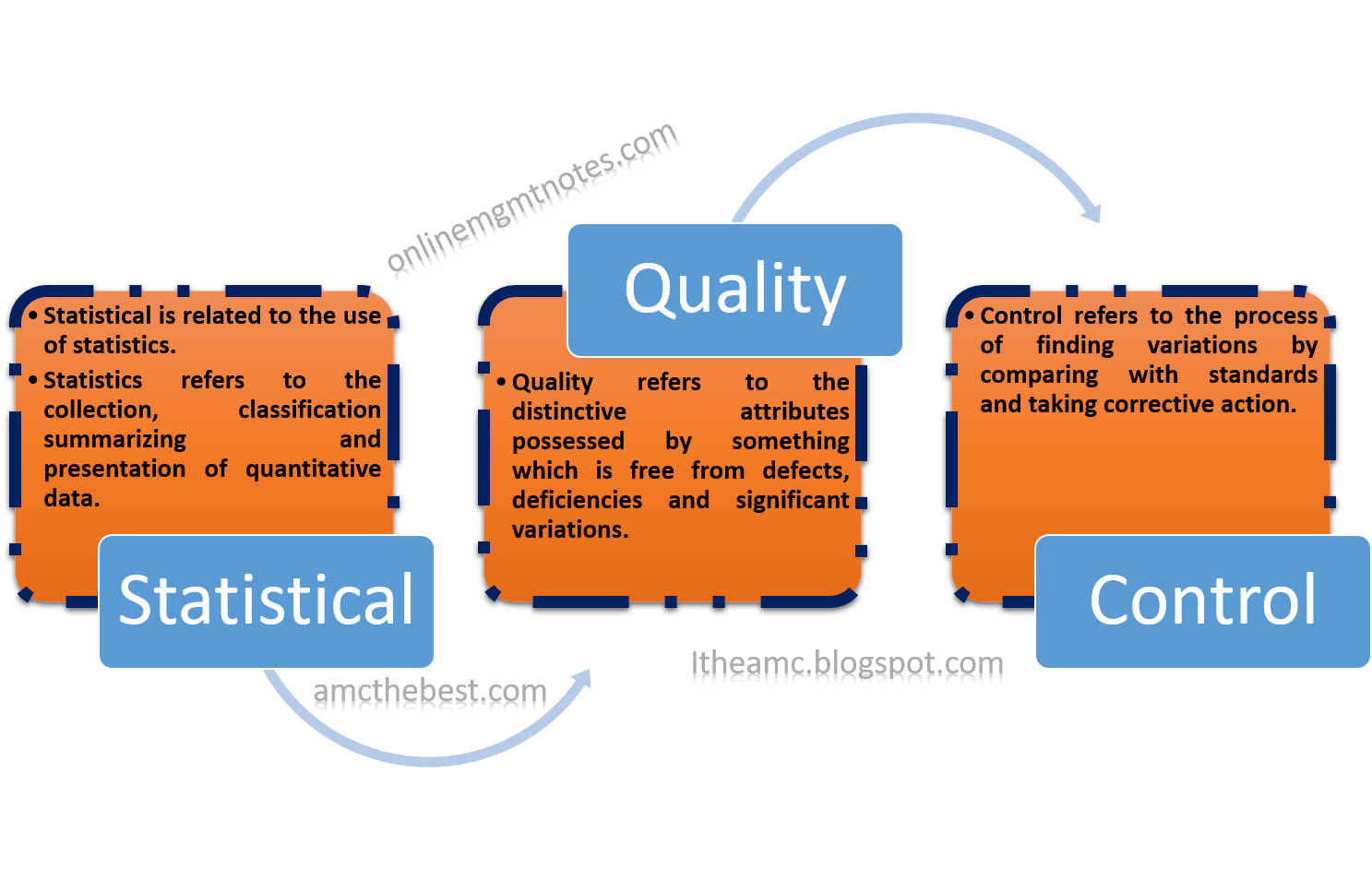

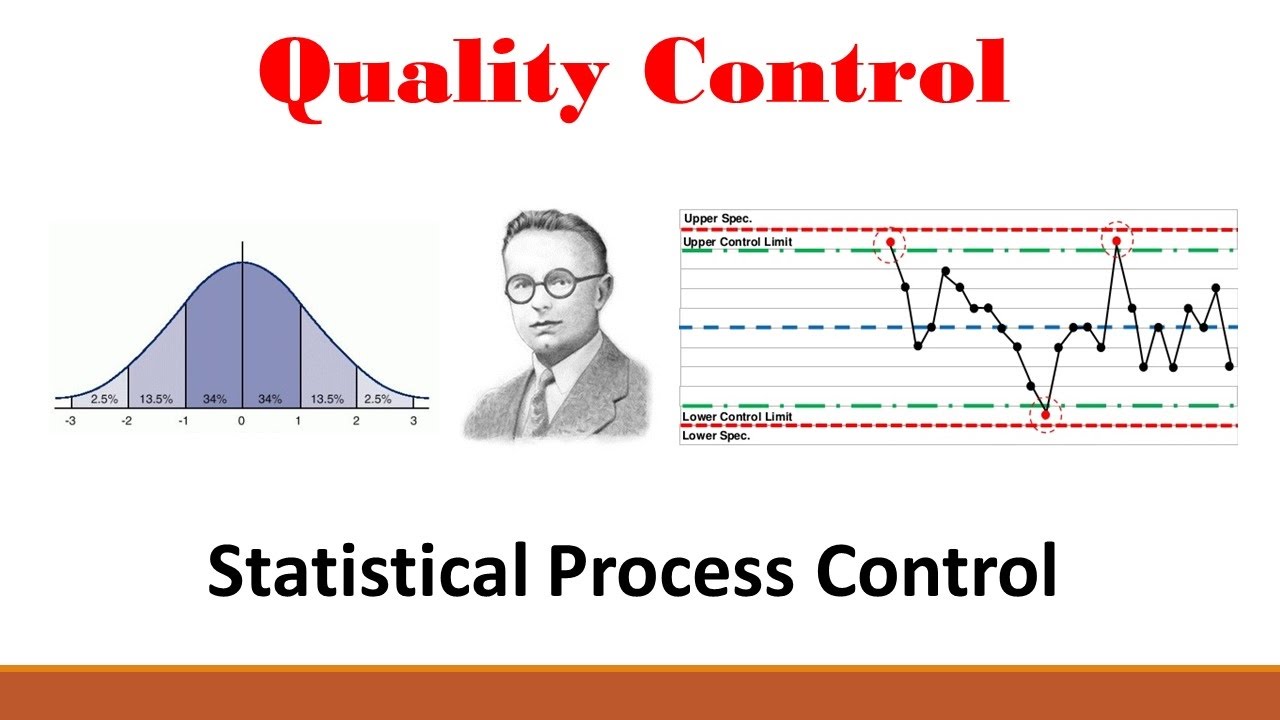

Statistical quality control (SQC) is defined as the application of the 14 statistical and analytical tools (7-QC and 7-SUPP) to monitor process outputs (dependent variables). Statistical process control (SPC) is the application of the same 14 tools to control process inputs (independent variables). Statistical process control ( SPC) or statistical quality control ( SQC) is the application of statistical methods to monitor and control the quality of a production process. This helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste scrap.

What does Statistical Quality Control (SQC) mean? Expand Your Knowledge

Statistical Quality Control Lean Tools in Apparel Manufacturing, 2021 Testing and statistical quality control in textile manufacturing A. Das,, in Process Control in Textile Manufacturing, 2013 3.2 Basic measurement concepts in statistical quality control SQC comprises the set of statistical tools used by quality control professionals. Statistical methods in quality improvement are defined as the use of collected data and quality standards to find new ways to improve products and services. They are a formalized body of techniques characteristically involving attempts to infer the properties of a large collection of data. Statistical process control (SPC) is a quality management technique used to monitor and control industrial processes by analyzing and interpreting statistical data. A new statistical quality control planning tool, called 'Westgard Sigma Rules,' provides a simple and quick way for selecting control rules and the number of control measurements needed to detect medically important errors. The concept of a quality control plan is described, along with alternative adaptations of a total quality control plan.

PPT المحاضرة الثانية تقنيات الضبط الإحصائي للجودة Statistical Quality Control Tools PowerPoint

The seven basic tools stand in contrast to more advanced statistical methods such as survey sampling, acceptance sampling, statistical hypothesis testing, design of experiments, multivariate analysis, and various methods developed in the field of operations research. [10] See also A3 problem solving - Structured problem improvement approach statistical quality control, the use of statistical methods in the monitoring and maintaining of the quality of products and services. One method, referred to as acceptance sampling, can be used when a decision must be made to accept or reject a group of parts or items based on the quality found in a sample. Quality: A Brief Introduction. The main objective of statistical quality control (SQC) is to achieve quality in production and service organizations, through the use of adequate statistical techniques. The following survey relates to manufacturing rather than to the service industry, but the principles of SQC can be successfully applied to either. The statistical tools are a key element to support quality management and production process analyses, allowing managers to anticipate, in various ways, the situations that will arise. After a general introduction to statistics, this chapter discusses the main statistical techniques used to describe, visualize, and analyze data, with particular.

7. Statistical Quality Control

Statistical quality control consists of three main pillars: Descriptive statistics Statistical values such as the mean, standard deviation and range are used to describe the attributes of a selected sample of products.; Acceptance sampling Products are typically selected at random and various criteria are statistically assessed. On the basis of whether these criteria meet predefined standards. What are the 7 basic quality tools? Stratification Histogram Check sheet (tally sheet) Cause and effect diagram (fishbone or Ishikawa diagram) Pareto chart (80-20 rule) Scatter diagram Control chart (Shewhart chart)

Statistical quality control is an application of statistical techniques to measure and inspect the quality of a product, service or process. Explaining SQC vs SPC also in the blog. Statistical Quality Control is a branch of statistics. Data are two types (variables, Attributes). Variables measure-Length, Diameter, Volume, Time, Temperature etc. Attributes count-Number.

Quality (Part 1 Statistical Process Control) YouTube

In addition to containing a robust suite of control charts and other statistical quality control tools and procedures, the NCSS solution is a comprehensive statistical software package containing hundreds of analysis and graphics tools. Question: Statistical process control (SPC) is best defined as the use of. (A) Pareto charts to understand and control a process. (B) inputs to control critical and complex processes. (C) statistical methods to identify and remove manufacturing errors. (D) statistical methods to understand and control a process.