Vertical mills use a rotating cutting tool that most closely resembles a drilling machine or drill press. The drill chuck is mounted on a gantry above the bed of the mill and is lowered into the workpiece. The cutting tool is generally a single-pointed milling cutter. The vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock typically from metallic work pieces. Plastics and other materials can also be machined on the mill depending upon tooling and material. Mill controls may be manually operated, computer numerical controlled (CNC), or a combination of both.

Update more than 63 milling machine sketch in.eteachers

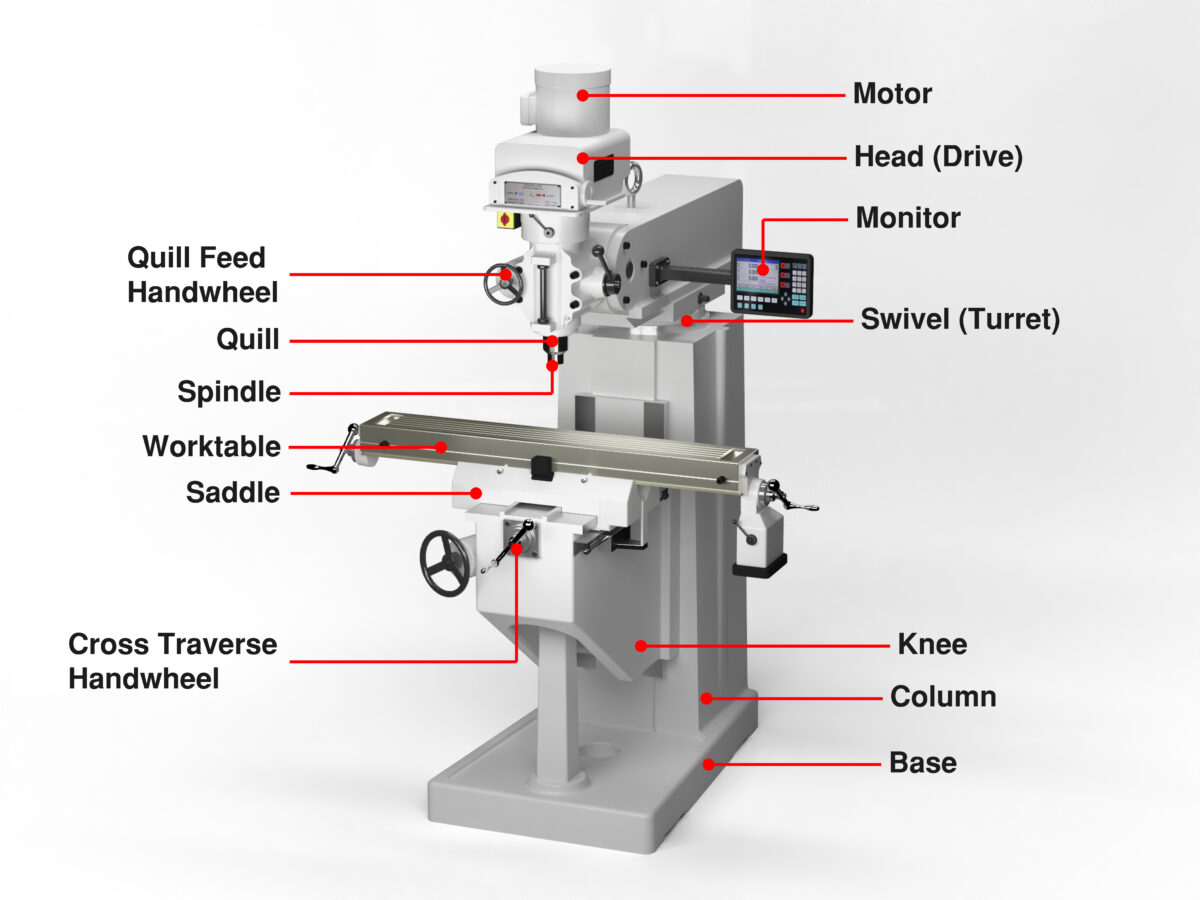

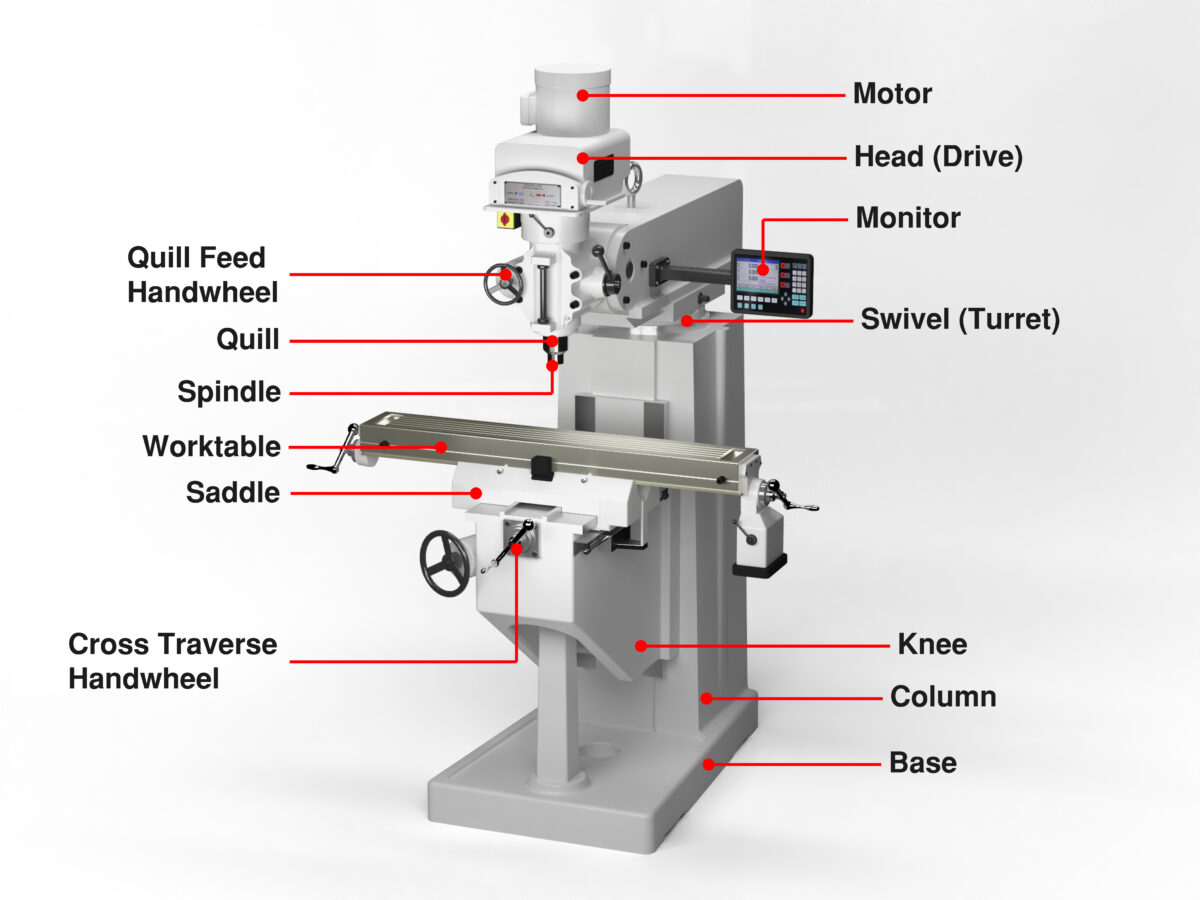

Figure 2. VMC Machine Coordinate System (At Home Position) As shown in Figure 12, when working with a CNC, always think, work, and write CNC programs in terms of tool motion, not table motion. For example, increasing +X coordinate values move the tool right in relation to the table (though the table actually moves left). Mr. Riggs explains the parts and functions of the vertical milling machine Bridgeport Vertical Mill (Manual) Purpose: Milling machines use the rotational motion of a stationary cutter to remove material from a workpiece. The position of the workpiece can be moved along all 3 of the machines working axes (X, Y, and Z). By advancing the workpiece into the rotating cutter, material is removed, and it is brought to the. In Vertical Milling Machine, the head is used to swiveled or it can be fixed. this can move in upward and downward directions and can move in any directions. Vertical Milling Machine is used to make a different type of operations like a flat surface, grooves, slots etc. Working of Vertical Milling Machine:

Jet Milling Machine Outlet Online, Save 60 jlcatj.gob.mx

SIMPLE DIAGRAM OF A VERTICAL MILLER A wide selection of cutting tools are available. They are made from high speed steel and are strong enough to cut through mild steel, cast steel and aluminium. Three examples are shown below with an example of the profile they cut into the metal. DIAGRAMS OF SOME CUTTERS PHOTOGRAPHS OF REAL LIFE CUTTERS Diagram of a milling machine VMCs can be equipped with multiple adjustments. For example, there are many angles of approach available as well as rotary and other positioning devices up on the worktable. Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment. Context 1. structure of the mechanism offers good force and speed transmission ratios of the platform with driving forces and speeds without problems with singularities. A variant of the.

Vertical Milling Machine Parts In Hindi Basic YouTube

Download scientific diagram | Vertical Milling Machine from publication: Optimization of process parameters for Milling Using Taguchi Methods | The Present work deals with the effects of various. GENERAL DESCRIPTION At first glance, a vertical mill looks similar to a drill press, but there are some important design differences; for example, a spindle that can take side loads as well as end loads and an accurate method of moving work in relation to the spindle on all three axes.

The process of removing material from a workpiece by advancing rotary cutters cutter into it is called milling. The process is carried out by adjusting pressure, speed of cutter head, and direction of feed. A milling machine is a piece of equipment that removes a layer of material from the surface by using a multi-point cutting tool. MILLING MACHINES Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. Part No. M -0009500-0450 June, 2003 TP5260. Information in this manual is subject to change without notice. This manual covers installation, operation, maintenance, and parts list for. safeguarding for vertical milling machines.

Grizzly Milling Machine Shop Official, Save 61 jlcatj.gob.mx

Vertical Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece, and occurs a vertical machining center (VMC), which employs a spindle with a vertical orientation.. Vertical Machines: Ez Series VC-Ez 16 VC-Ez 16X VC-Ez 20 VC-Ez 26 VC-Ez 32. FJV FJV 5 Face-100/120 FJV 5 Face-100/160 FJV 5 Face-35/120 machine startup and machining restart. To stabilize thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced. World's first "Collision-Free Machine" CAS prevents collisions in automatic or manual mode, providing risk-free protection for the machine and great