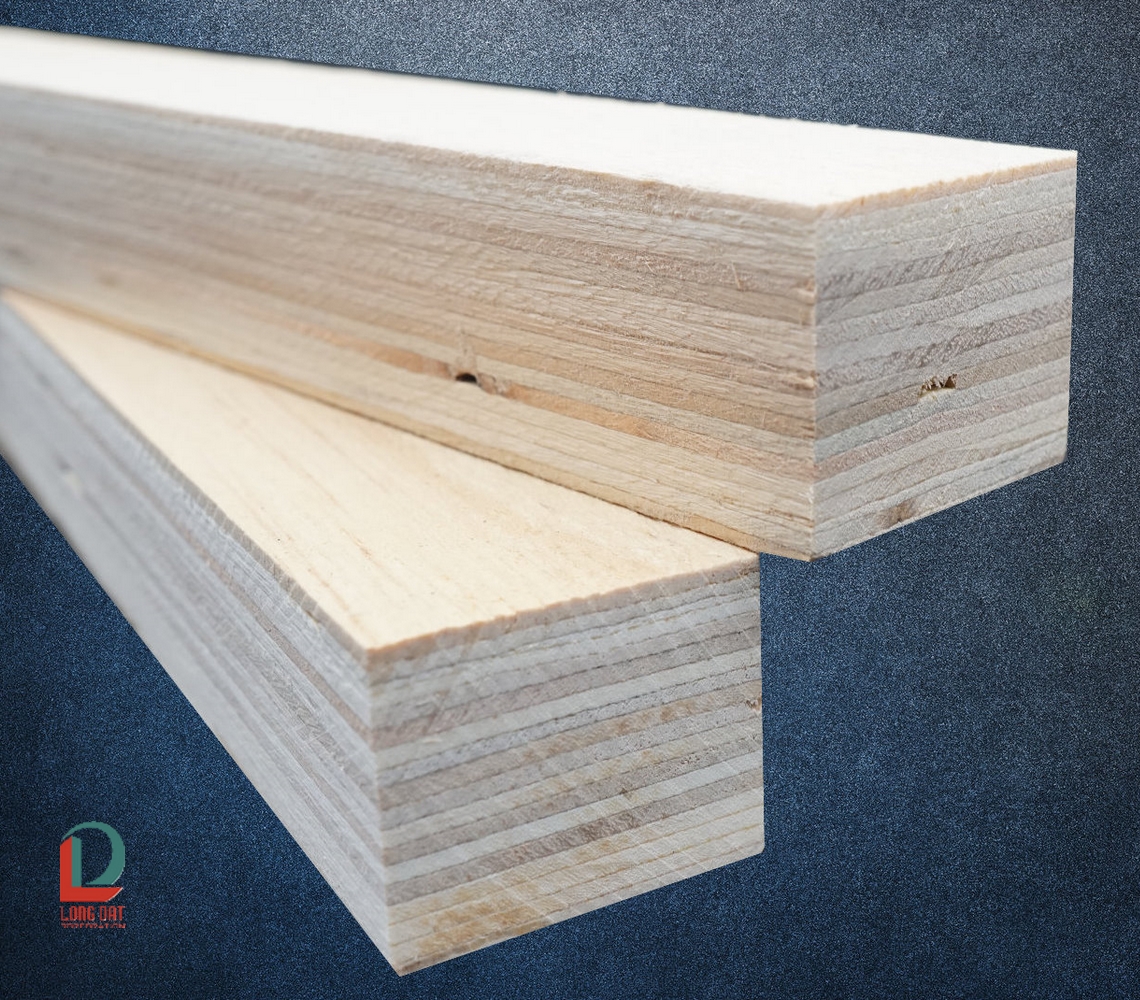

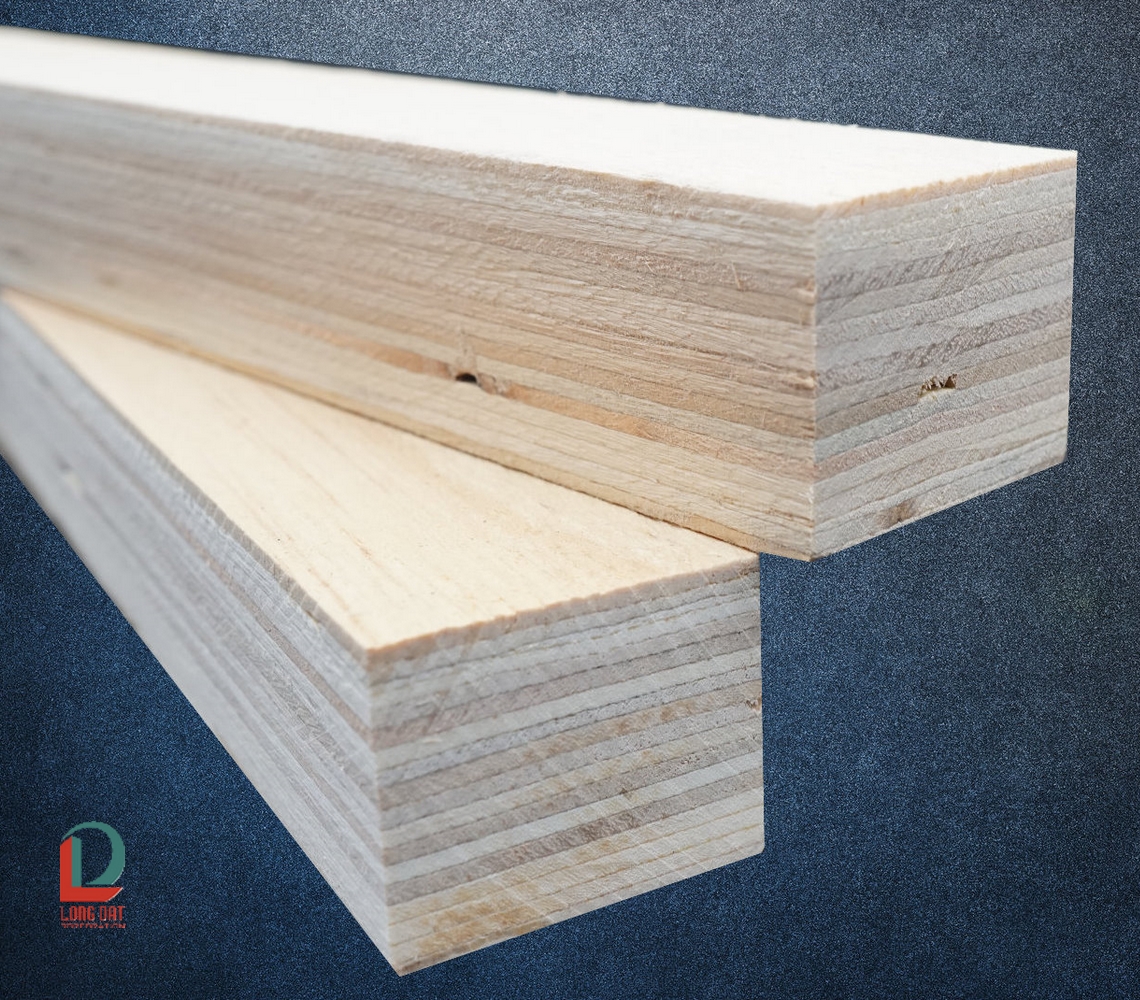

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL is part of a family of products, structural composite lumber (SCL), that are made of dried and graded wood veneers, strands or flakes that are layered upon one another and bonded together with a moisture resistant adhesive into large blocks known as billets.

Laminated Veneer Lumber (LVL) Gallery

Laminated veneer lumber (LVL) is one of the most widely used engineered wood products for constructional applications. It is a composite product manufactured from multiple thin layers of veneer that are aligned with the length of the finished lumber. Laminated veneer lumber (LVL) is a high-strength engineered wood product, and one of the most widely used kinds of lumber in construction projects. It's used for boards of all kinds, including rim boards, headboards and even skateboards, as well as beams, trusses and more. Lowe's features LVL in a wide range of lengths, widths and thicknesses. RigidLam® LVL ENGINEERED WOOD Laminated veneer lumber beams, headers, columns and studs for strong, straight open concept residential and commercial spaces. Backed by a product and performance warranty, RigidLam LVL provides a better alternative to traditional, solid sawn lumber. The product is stronger, stiffer, and a more predictable. What Laminated Veneer Lumber (LVL) Is Pros Good overall strength Good weight-to-strength ratio Stable Consistent quality Excellent size-to-strength ratio Cons Expensive Special order item Installation specifics to be followed Defects like warping possible Not always exterior-rated

LVL lumber laminated veneer lumber Ultralam Official website Russia

Synopsis: Laminated-veneer lumber (LVL) combines the versatility of sawn lumber with the strength of engineered beams, according to John Spier. In this article, Spier talks about how to build up center carrying beams and two different ways they can support a floor frame (flush beam or dropped beam). Laminated veneer lumber (LVL) is an engineered wood construction product. LVL is made of multiple veneer sheets and assembled with waterproof adhesives. It is used in headers, beams, rim boards, truck bed decking, roadway signposts, trusses, and many other applications. LVL is an innovation for the construction field. Laminated Veneer Lumber, widely known as LVL, is an engineered wood product that combines technology and nature. Designed with the objective of optimizing the natural properties of wood, it provides robustness and adaptability that are difficult to achieve with traditional timber. It has carved out a distinct niche in the world of modern. LVL Panels. Vertically laminated veneer lumber (LVL) panels are made from "peeler logs" in the same production lines as LVL beams. Engineered to precise design values and with a very high strength-to-weight ratio, LVL panels are suitable for structural wall, floor and roof applications. With increasing interest in mass timber use for.

RedLam™ LVL Beams, Headers and Columns Laminated Veneer Lumber

Boises Laminated veneer lumber (LVL) is a product that uses multiple layers of thin wood assembled with adhesives. LVL offers several advantages over typical milled lumber: Made in a factory under controlled Kerto® LVL is structural laminated veneer lumber used in all types of construction projects, from new buildings to renovation and repair. Kerto LVL combines excellent technical performance with ease of use. Its essential qualities include strength and rigidity, dimensional stability and light weight.. Kerto LVL is produced from 3 mm thick.

LVL is available in lengths up to 24.4 m (80 ft), while more common lengths are 14.6 m (48 ft), 17 m (56 ft), 18.3 m (60 ft) and 20.1 m (66 ft). LVL can easily be cut to length at the jobsite. All special cutting, notching or drilling should be done in accordance with manufacturer's recommendations. Laminated veneer lumber (LVL) is a mass timber product that is twice as strong as steel in proportion to weight. It provides an ideal solution when strength, dimensional stability, and high load-bearing capacity are essential. Photo: Aalto-yliopisto & Stora Enso / Vesa Loikas What is LVL?

Laminated Veneer Lumber

Laminated veneer lumber (LVL) is a type of engineered wood that is made by bonding together thin layers of wood veneers. LVL is often used as an alternative to solid lumber in construction projects, as it is stronger and more resistant to warping. However, there are some things to consider before using LVL in your next project. To make STEICO LVL (Laminated Veneer Lumber), debarked softwood logs are put in hot water to soften and are then peeled into veneer layers in a rotation process.The veneers are dried, sorted, glued, pressed and cut to their final format. The clever bit: where naturally grown wood has flaws, such as knots, stretching over the entire cross-section, STEICO LVL restricts the flaw to a single sheet.