A 3D printing brim is a flat extension of the first layer, enhancing bed adhesion and reducing warping, especially for small, tall, or warp-prone prints. Adjusting brim settings like width and line count tailors its effectiveness, though it requires extra post-processing for removal. 3D Printing Brim: When Should You Use It by Lauren Fuentes Updated Sep 3, 2022 Prevent warping, help with adhesion, and reduce waste - what's not to love about a 3D printing brim? Read on to learn more! Advertisement with personalized ads Accept and continue

3D Printing Brim Learn How to Print With Pick 3D Printer

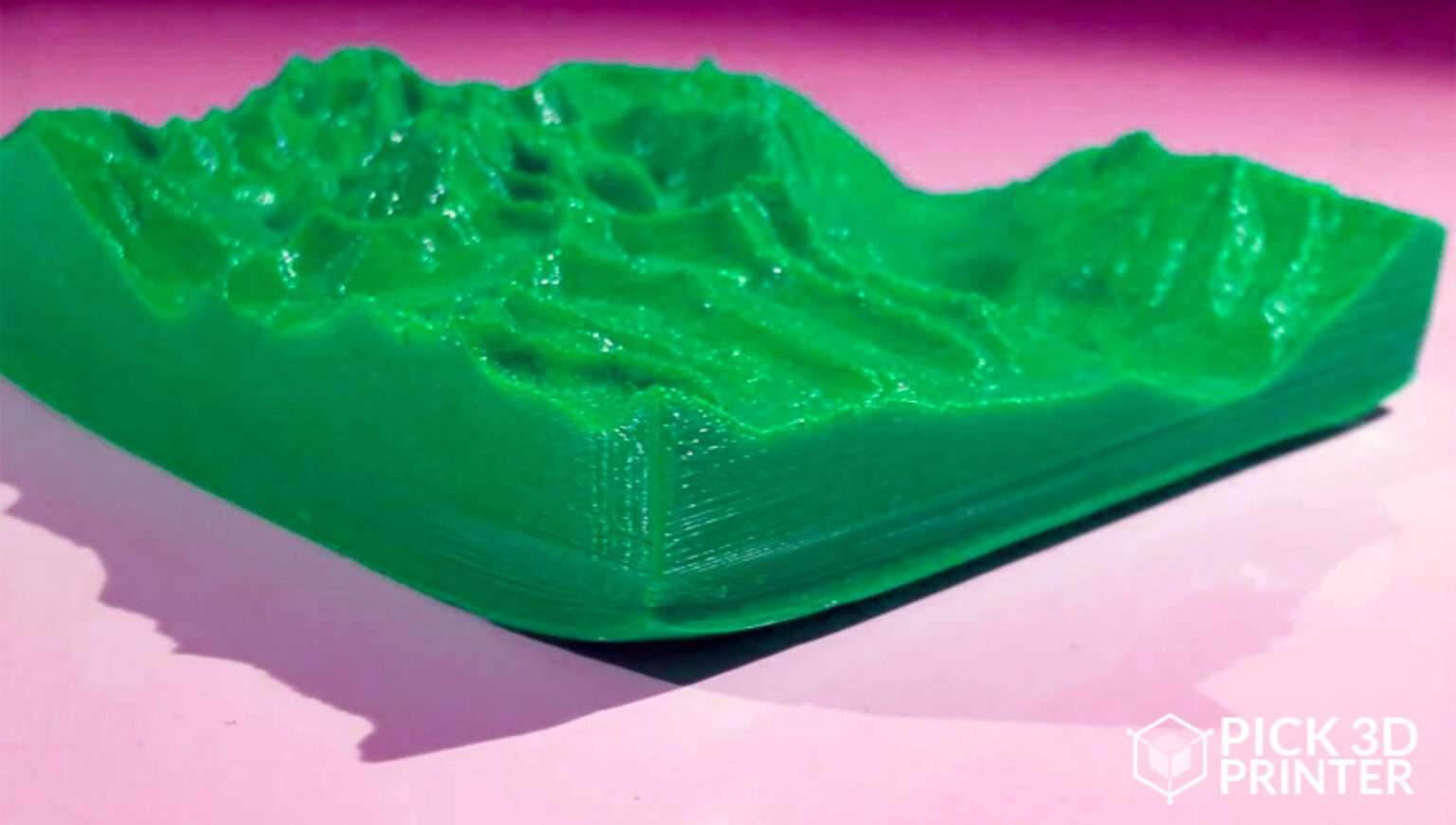

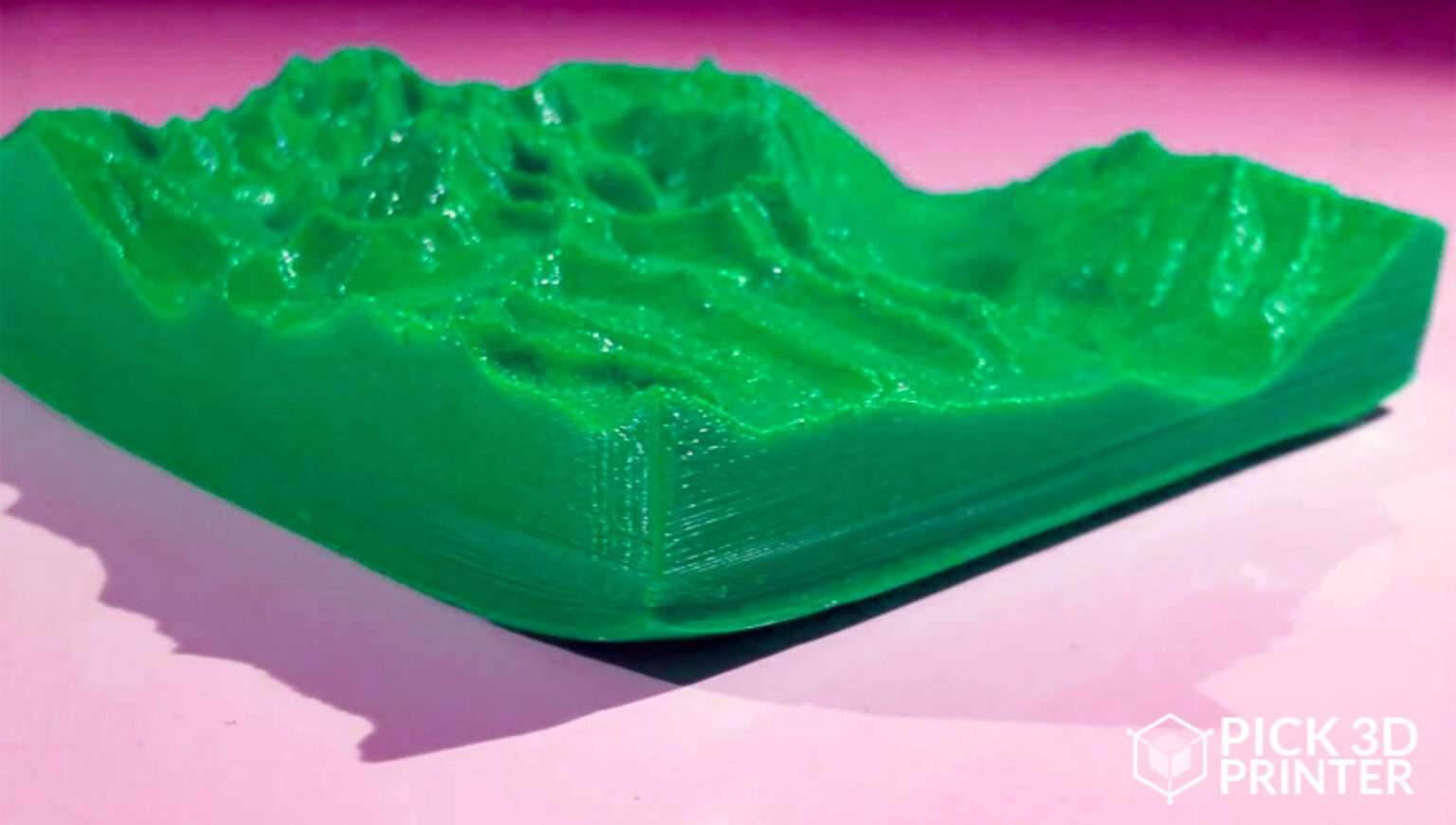

Benefits of 3D Printing Brim Some of the benefits of a brim in your designs include: Improved adhesion: As we have mentioned above, the primary purpose of a brim is to enhance adhesion. Rafts, brims, and skirts are key tools for ensuring firm first layers and preventing warping for your 3D prints. In this guide, I'll explain all the key differences so you can decide which is right for your project, as well as the settings you'll need to use them effectively. 3D printing raft vs. brim vs. skirt: Learn the differences between these adhesion assistants and which to choose, using Cura as an example. The brim is present in the first layer of printing, it is an extended structure that surrounds the bottom of the 3D print. Adding a brim to a 3D print will extend the bottom layer of the model, increasing the surface area of the first layer. The 3D print brim provides more contact with the printing bed, which helps improve the bed adhesion of.

3D Printing Brim When Should You Use It

Brim This tutorial will help you understand the differences between rafts, skirts and brims. All three techniques provide a starting point for your 3D printed models, but they have different uses and advantages. Rafts A Raft is a horizontal latticework of filament that is located underneath your part. Cura is one of the most popular slicers for 3D printing. Clear display, ease of use and support for all possible file formats are just a few arguments in favor of the slicer. Although Cura belongs to Ultimaker, it also supports 3D printers from other manufacturers - which is of course perfect. Raft A Raft is a support construction that lifts the actual workpiece off the print bed. A thin layer of filament is printed as a "base" before the actual printing begins. The technology dates back to the early days of 3D printers. Older generations in particular had problems with the adhesion of the print bed. Extending along the print bed of your 3D printer, a 3D printing brim is a layer of material that is produced from the edges of the part of a functional prototype. There is another terminology that you might easily confuse brim with and that is a raft.

3D printing using brim, raft, and skirt? What should you use?

What is a Brim & Raft in 3D Printing? Best Ways for Removing Rafts & Brims From 3D Prints Using The Proper Software Settings Cutting The Rafts Off Sanding Use Soluble Materials When Should You Use a Raft for 3D Printing? Use a Raft To Eliminate Warping Get Better Print Bed Adhesion With a Raft Use a Raft to Increased Stability Skirts, Rafts, and Brims are the different base layer techniques used to print your 3D model with better success. These techniques are popular and useful to us because they give a stronger base and make the filament flow smoothly after laying the base layer, which then hopefully adheres correctly.

1. Understanding the Role of Brim in 3D Printing: A Beginner's Guide 📌 Brim is a crucial element in 3D printing, serving multiple purposes. It acts as a foundation for the printed. The 3D printing brim function is an extremely useful mode as it uses less material, helps create that desired bottom layer, and most importantly, it's easily removable. Being that the mode creates a flat area on the first layer around the model's base, it both increases the contact area and improves the adhesion..

The need of brim and support for learning FDM 3D printer YouTube

By understanding the different types of build plate adhesion: skirts, brims and rafts, you can increase the chance of successful 3D prints. They can be found in the slicer setting, once activated, they work to detect problems for your printer and improve bed adhesion. As for which one is the most suitable for FDM 3d printer, it still depends on. 5 Easy Fixes for 3D Print Brim Not Sticking. If you've tried to print a brim but been unsuccessful, try one of the following fixes: 1. Set the Bed at the Right Temperature. The best way to prevent the brim from detaching is by heating the bed surface first. 3D printers have different filament types that stick differently at a given temperature.