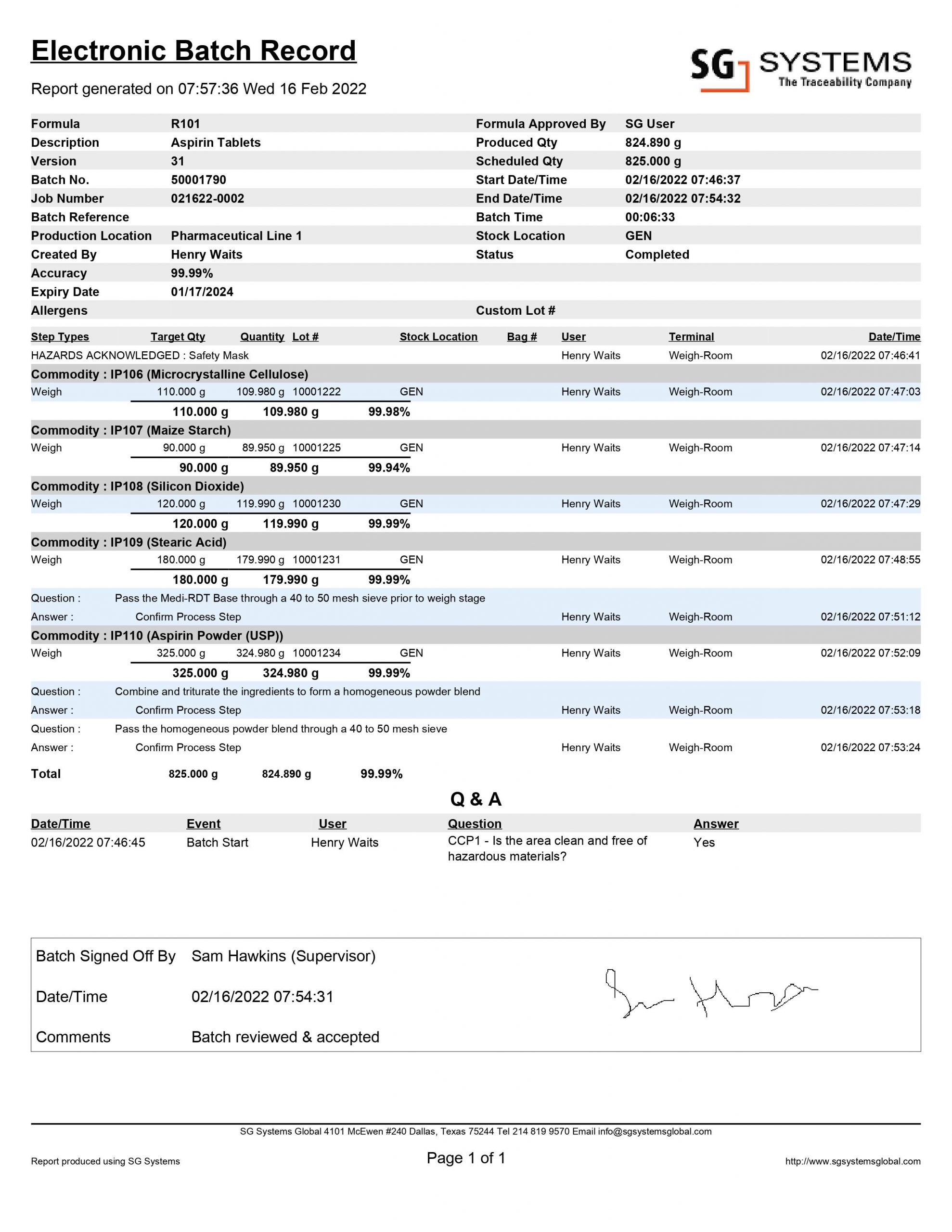

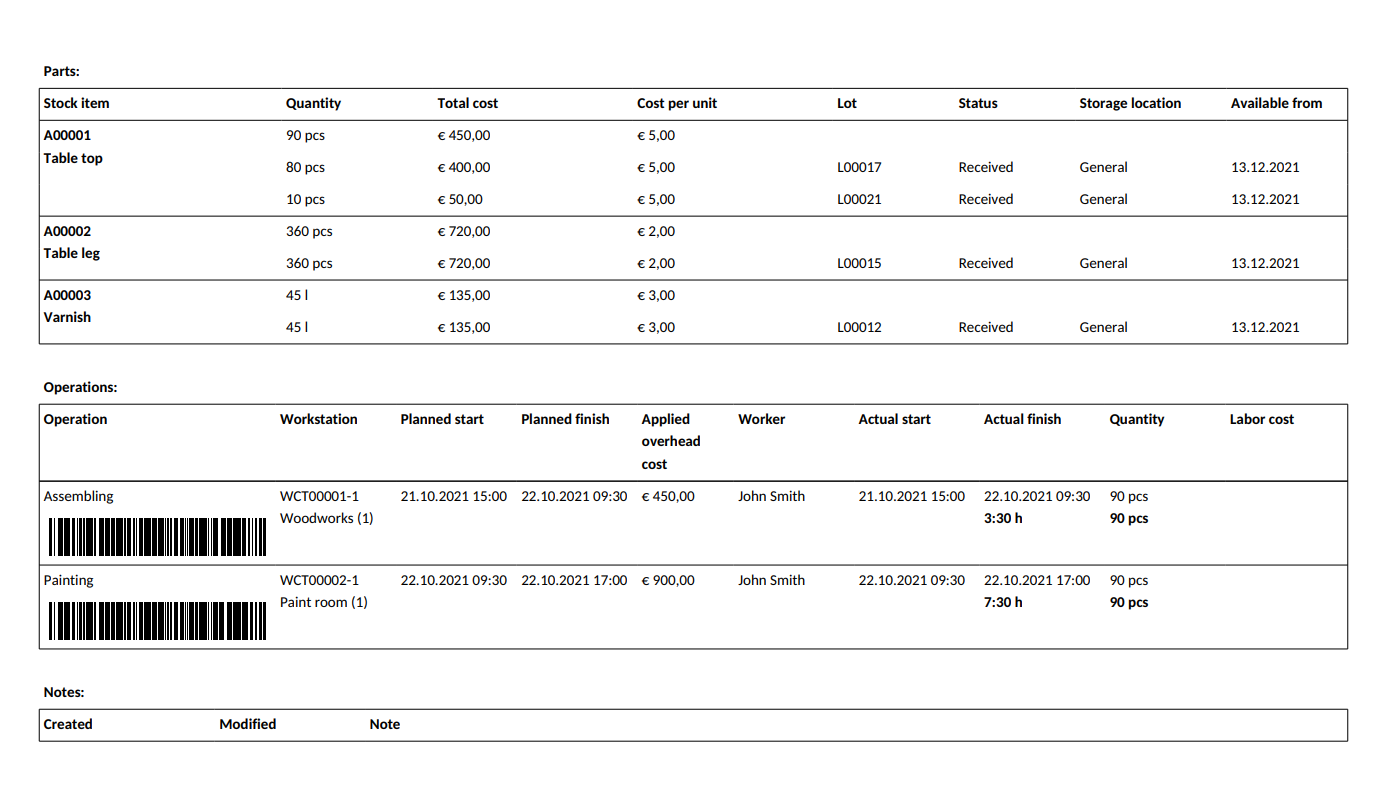

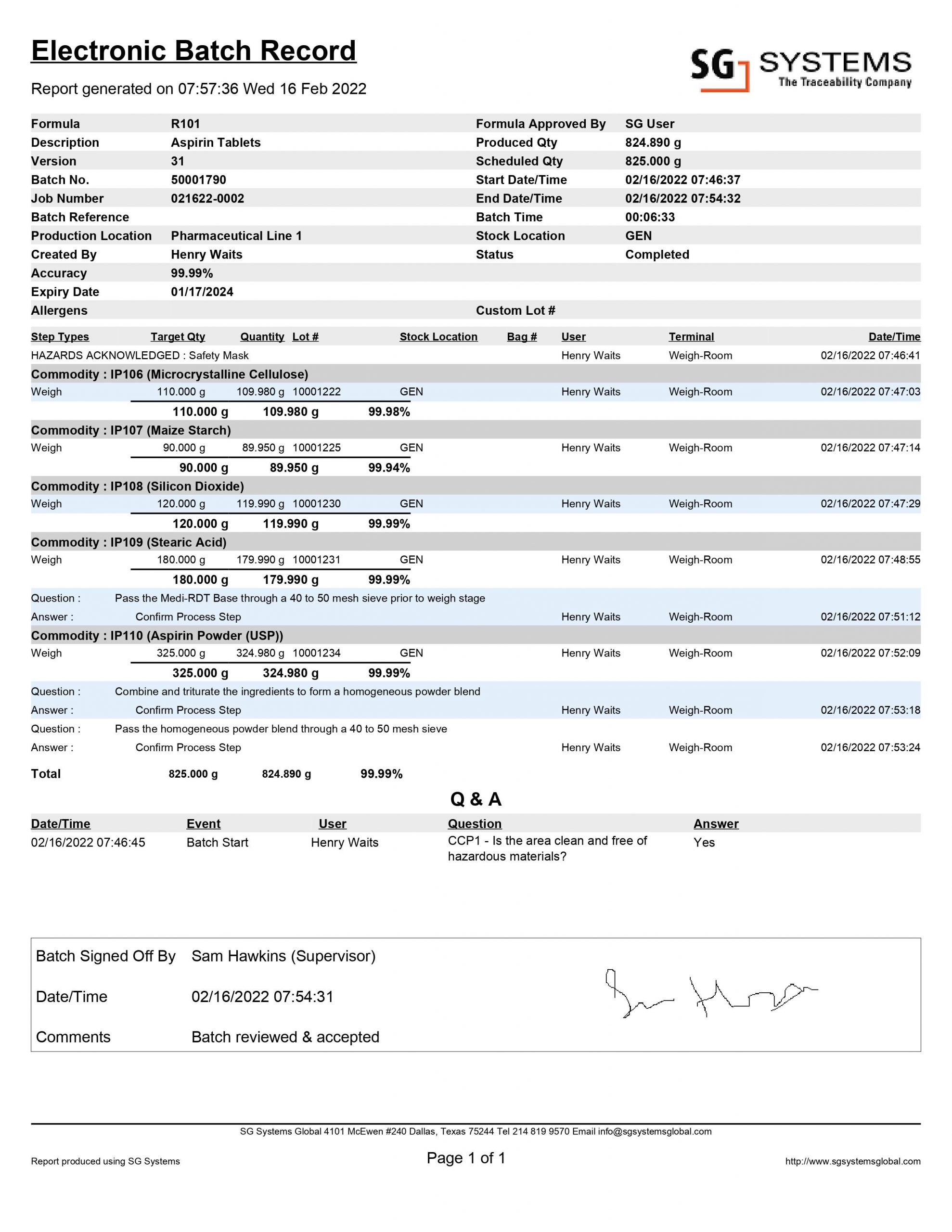

A batch manufacturing record (BMR) is an important document for chemical and process manufacturers: It tells users how to produce a batch of a given product, then records the entire production process, from start to finish. Batch Manufacturing Records (BMR) are essential to any pharmaceutical or medical device manufacturing. These documents allow manufacturers to track and document the production process and ensure product quality. From start to finish, batch records provide an audit trail of the manufacturing process and the materials used.

Batch Manufacturing Record (BMR) and BPR

A batch record is a comprehensive set of documents that outlines all aspects of the Batch manufacturing records (BMRs) Batch production records (BPRs) Master production records (MPRs) This is the most comprehensive type of batch record. It includes all the data associated with the manufacturing process, from raw materials to Batch manufacturing record is a written document from the batch that is prepared during the pharmaceutical manufacturing process. It contains actual data of the batch manufacturing and whole manufacturing process step by step. There are several stages of the pharmaceutical product manufacturing process. A batch manufacturing record (BMR) is a comprehensive document that outlines the entire production process for a specific batch of a product. It serves as a detailed guideline for manufacturers to follow in order to ensure consistency and quality control throughout the manufacturing process. What should be included in a batch manufacturing record? A Batch Manufacturing Record (BMR) is a document that contains step-by-step documentation of the entire manufacturing process involved in producing a product batch, including the expected batch yields and labeling requirements.

Sample of Batch Manufacturing Record (BMR) Atorvastatin PDF Download M A N O X B L O G

The batch manufacturing record (BMR) is a document containing the instructions that must be followed when manufacturing medication. It includes information like product name, weight and count of each component in the medication, a list of all processes and procedures to follow, and the expected yield of each batch. G. Batch Production Record Review (6.7) Written procedures should be established and followed for the review and approval of batch production and laboratory control records, including packaging. A batch manufacturing record is a written and validated narration of the end-to-end manufacturing process. It includes the records of production, instructions on how to manufacture a product, quality control measures, the procedures involved, inspection reports, and the report on the outcome. A master batch record (MBR), also known as a master production record (MPR) is a document that contains the approved ingredients, formulation, and instructions guiding the production of a pharmaceutical product. The document enables manufacturers to follow the necessary regulatory guidelines when manufacturing a product.

Electronic Batch Record (EBR) 21 CFR Part 11 Digital Compliance

The following features can also important for prep batch manufacturing records by the chemical and process manufacturing industry: Step-by-step instructions additionally authentications. BMR software doing a copy a the master formula record, auto-populating instructions how users have lead thru the manufacturing process step by step without. A batch manufacturing record, or BMR, is a document containing the details of the manufacture of each product batch, across the whole manufacturing process. As there are many stages in the manufacturing process, each step must be recorded as proof, from obtaining the raw materials through to the final stage of packaging ready for sale.

In pharmaceutical manufacturing, MES most often means using electronic batch records (EBR) — a digital record that provides proof of a product's batch record with details on process steps, equipment information, materials and supplies. The MES system is centered in manufacturing operations with connections to other foundational business and. Batch Manufacturing Record (BMR) In the pharmaceutical industry, a Batch Manufacturing Record (BMR) is an essential document used to monitor and control all steps in pharmaceutical production processes. It contains detailed information about how a specific batch of pharmaceutical products was produced. A BMR typically includes details on raw.

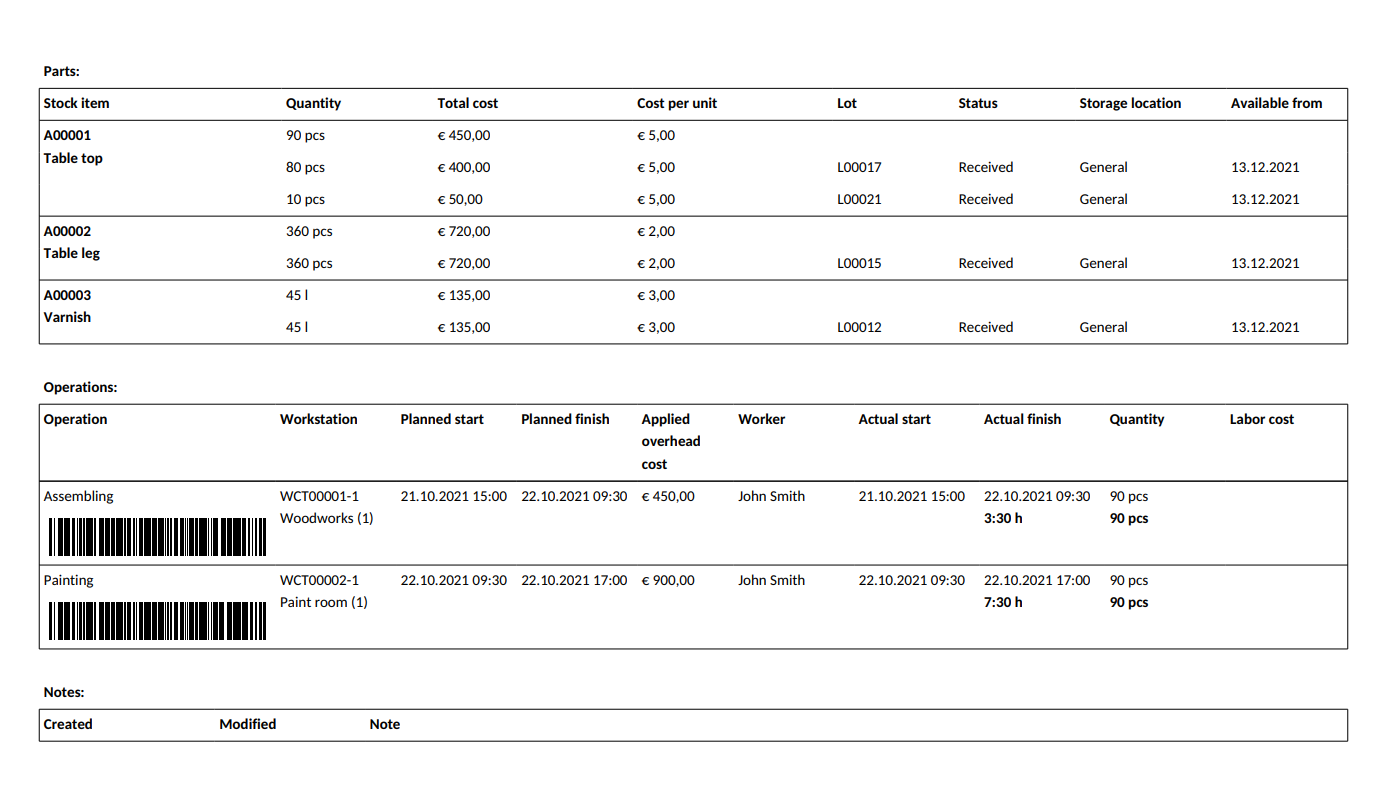

How to Keep Perfect Batch Records? MRPeasy

July 25, 2023 | Business Tips Behind the Scenes: Unraveling the Structure and Components of Manufacturing Batch Records Producing a batch record to verify quality and compliance is an important administrative task for manufacturers, especially in highly regulated industries. A batch manufacturing record is a document designed to provide a complete record of the manufacturing history of a batch of product. The terminology is widely applied within the Pharmaceutical & Chemical industries and is referenced in many of the pharmaceutical and food regulatory agency requirements. The US Food and Drug administration.