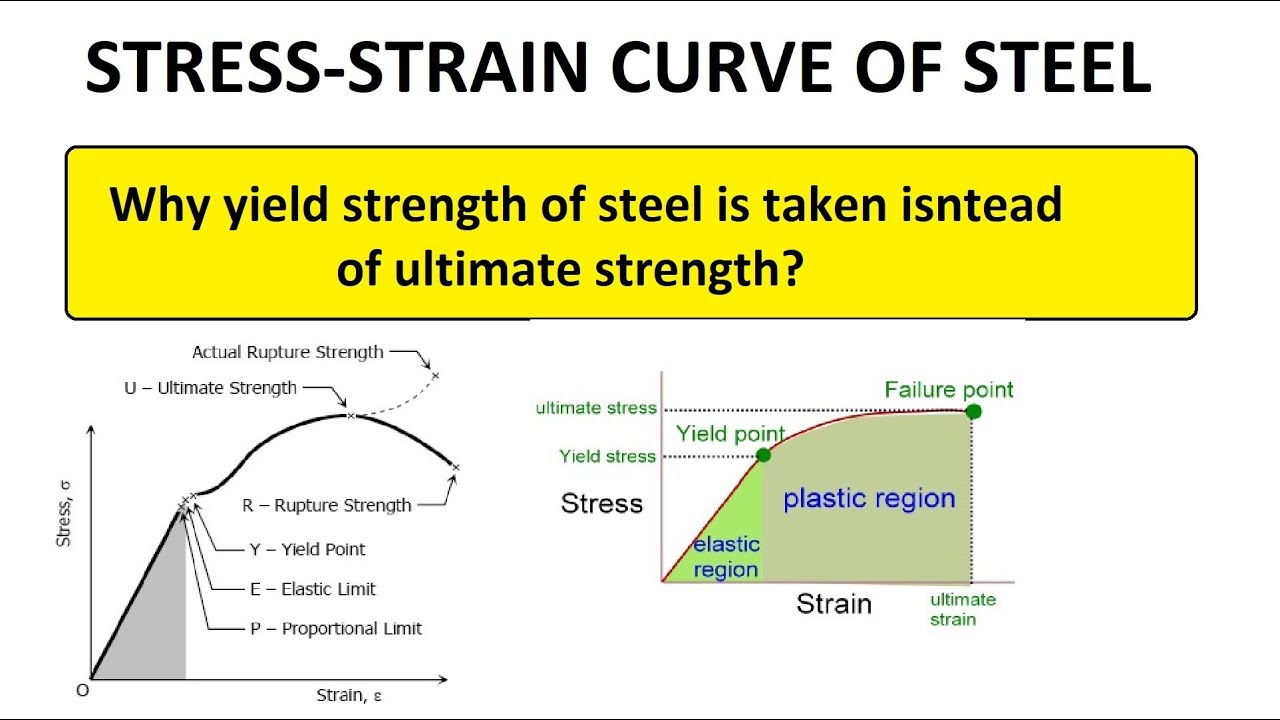

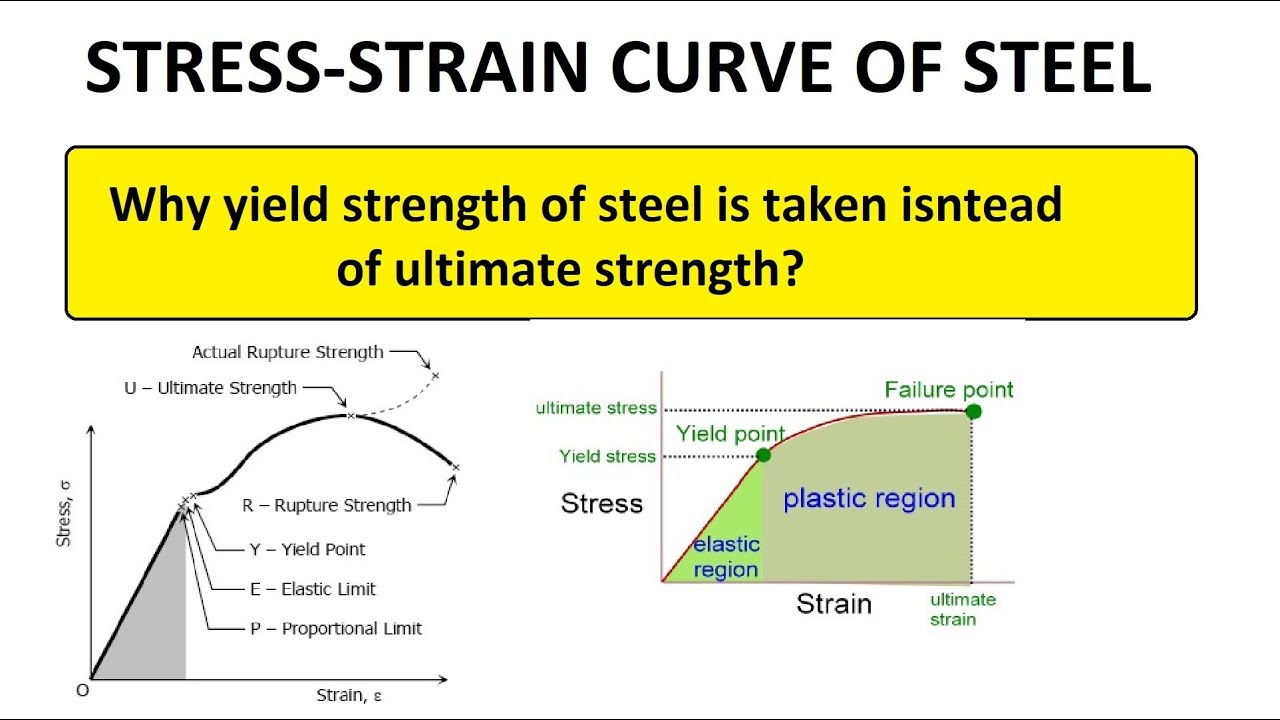

Whereas, tensile strength is the maximum tensile stress beyond which a material fails and breaks. One property can be considered more important than the other depending on the type of material. If the material is ductile, yield strength is usually the more prominent property to consider, while tensile strength takes precedence in brittle materials. The main difference between yield strength and tensile strength is that yield strength is the minimum stress under which a material deforms permanently, whereas tensile strength describes the maximum stress that a material can handle before breaking. Stress - Strain Characteristics of a Material

Difference between Yield Strength and Ultimate Strength YouTube

Differences Between Tensile and Yield Strength 1. Definition Tensile Strength: Represents the maximum stress a material can endure while being pulled or stretched. Yield Strength: Indicates the stress at which a material begins to undergo permanent deformation under tension. 2. Behavior Under Load It can be used to predict the elongation or compression of an object as long as the stress is less than the yield strength of the material. More about the definitions below the table. Young's Modulus, Tensile Strength and Yield Strength Values common Materials 1 Pa (N/m2) = 1x10-6N/mm2= 1.4504x10-4psi Yield strength is the maximum stress a material can withstand and still return to its original shape. After that point, the material will remain deformed, even after the stress is removed. Like tensile strength, yield strength can increase or decrease depending on the material's temperature. The biggest difference is that tensile strength is catastrophic, where yield strength is only a permanent deformation. Below we will go into more details about both of these, as well as talk about what elongation is in respect to tensile strength. What Is Tensile Strength? Tensile by definition means capable of being drawn out or stretched.

Yield Strength vs. Tensile Strength 6 Key Differences, Pros & Cons, Examples Difference 101

1. Yield Criteria Three commonly used yield criteria in engineering are: (1) Proportional Limit - The highest stress that maintains a linear relationship on the stress-strain curve, internationally represented as σp. Material is considered to start yielding when stress exceeds σp. The main difference between yield strength and tensile strength is that under yield strength, a material changes its form completely, while tensile strength is the stress which a material can handle before it breaks. Let's take a closer look at Tensile Strength vs. Yield Strength Table of Contents What Is Yield Strength? Yield strength refers to the point at which a material undergoes permanent deformation or a significant change in shape due to applied stress, signaling its transition from elastic to plastic behavior. On the other hand, tensile strength represents the maximum amount of stress a material can withstand before it fractures or breaks. #yieldstrength #tensilstrength #metals #materials Visit https://link.matmatch.com/eqmat to find equivalent materialsVisit https://link.matmatch.com/EMtoMM to.

Yield Strength vs. Tensile Strength 6 Key Differences, Pros & Cons, Examples Difference 101

The tensile strength and yield strength of a metal decide its areas of application. In the case of larger projects, such as in the aerospace or construction industries, these factors are a matter of life or death. Designers make sure that the maximum stress never reaches the yield strength of the metal used. Yield Strength vs Tensile Strength. Tensile strength quantifies the force needed to pull a rope, wire, or a structural beam to the stage where it breaks. Specifically, the tensile strength of a material is the maximum amount of tensile stress that it can withhold before failure occurs. Yield strength, or the yield point, is described in.

10. Both yield strength and tensile strength are measures of a material's resistance to mechanical failure, but they signify different behaviors. Yield strength highlights the onset of plastic deformation, while tensile strength signifies the point of outright failure. Sumera Saeed. Oct 04, 2023. The difference between yield strength and tensile strength is that yield strength is the smallest amount of force that can start the beginning of the deformation of an object. However, tensile strength is just the opposite of that, being the maximum force to cause breakage in an object.

Yield and tensile strength of steel

Key differences between yield and tensile strength These are some of the major differences between yield strength and tensile strength: Yield strength is a measurement to determine the maximum stress that can be applied before permanent shape change is achieved in ductile materials. In summary, the key difference lies in their definitions and the points on the stress-strain curve at which they are measured. Yield strength is associated with the onset of plastic deformation, while tensile strength is associated with the maximum stress a material can endure before failure. In general, yield strength is used for designing.