Value stream mapping (VSM) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we'll dive into the ins and outs of VSM, including its history, benefits for product managers and examples of successful implementations. Een value stream-overzicht (value stream map, VSM) is een stroomdiagram dat de stappen illustreert en analyseert die nodig zijn om een product te produceren of dienst te leveren.

Value Stream Map Lean Six Sigma Groep

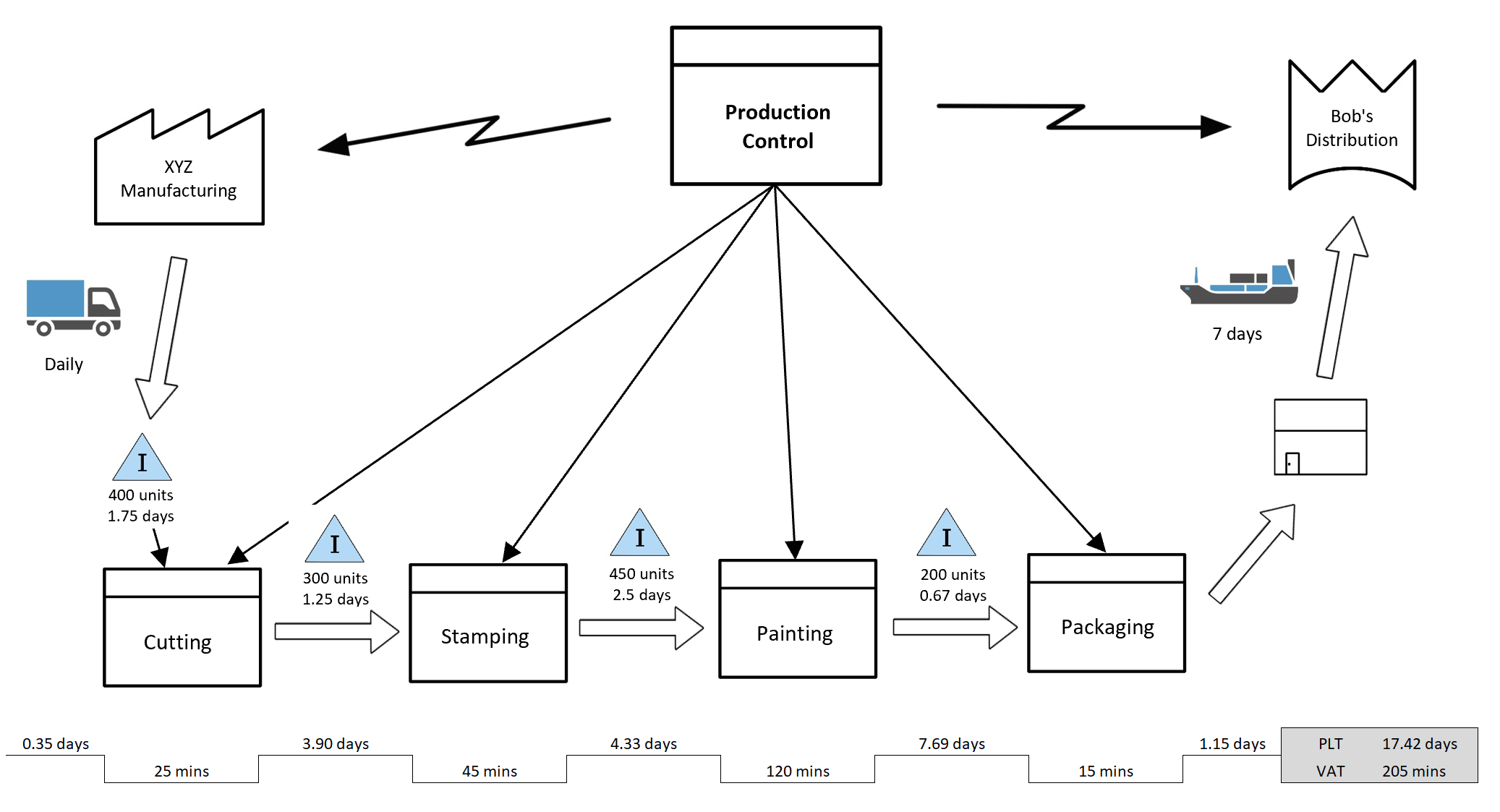

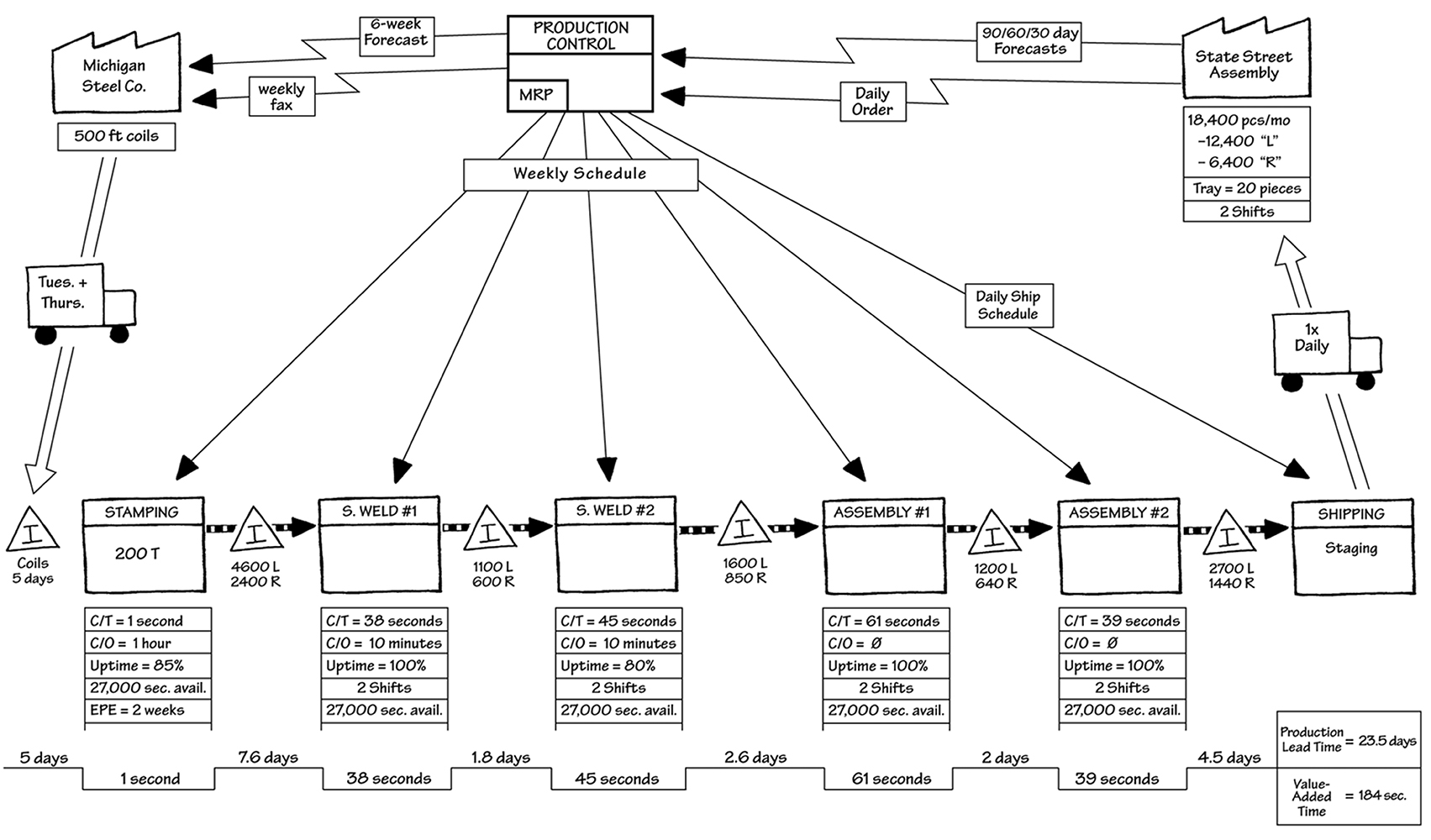

Value Stream Mapping allows analysis of the Current State Map in terms of identifying barriers to flow and waste, calculating Total Lead Time and Process Time and understanding Work-In-Process, Changeover Time, and Percent Complete & Accurate for each step. What is VSM? The ITIL ® 4 Foundation publication defines a value stream as a series of steps an organization undertakes to create and deliver products and services to consumers. Value stream maps are also one of the tools from Lean manufacturing. Create a value stream map. Click File > New. Type value stream map in the Search box, click the Start Searching button, and then double-click Value Stream Map when it appears. From the Value Stream Map Shapes stencil, drag shapes onto the page to represent your processes, information, and materials. Use the connector shapes from the Value. This current state map is a funnel-shaped value stream model. This model is used when there are large incoming amounts of material and fast initial processing. Click to commit the necessary changes. Funnel Shaped Value Stream Model (Click on the image to edit it online)

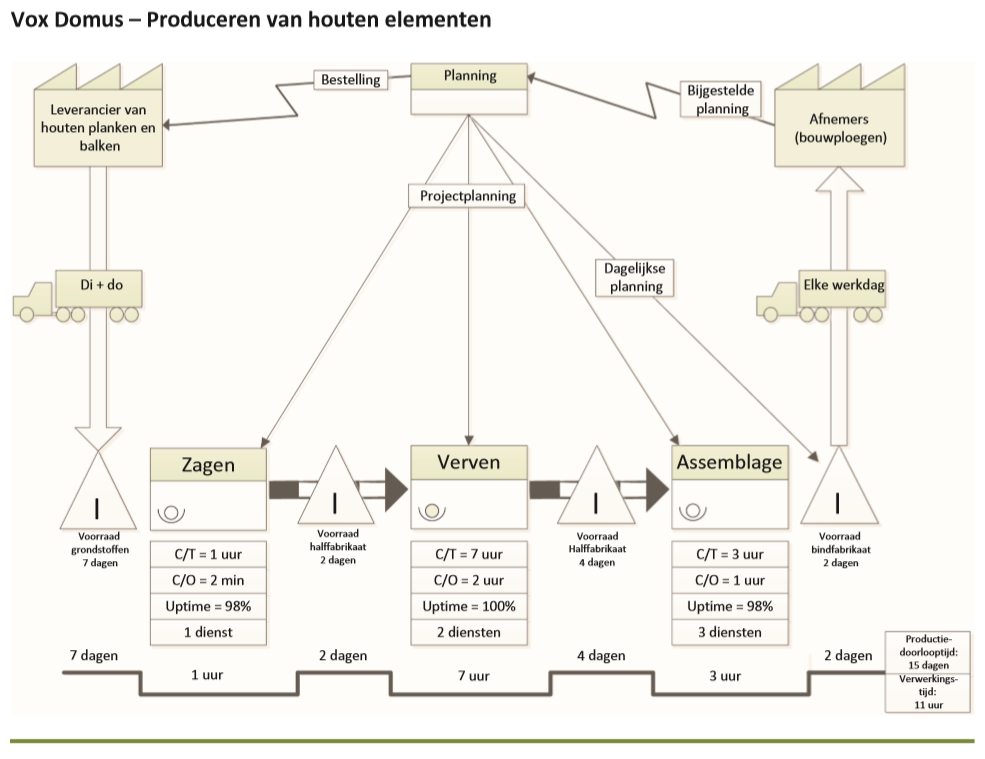

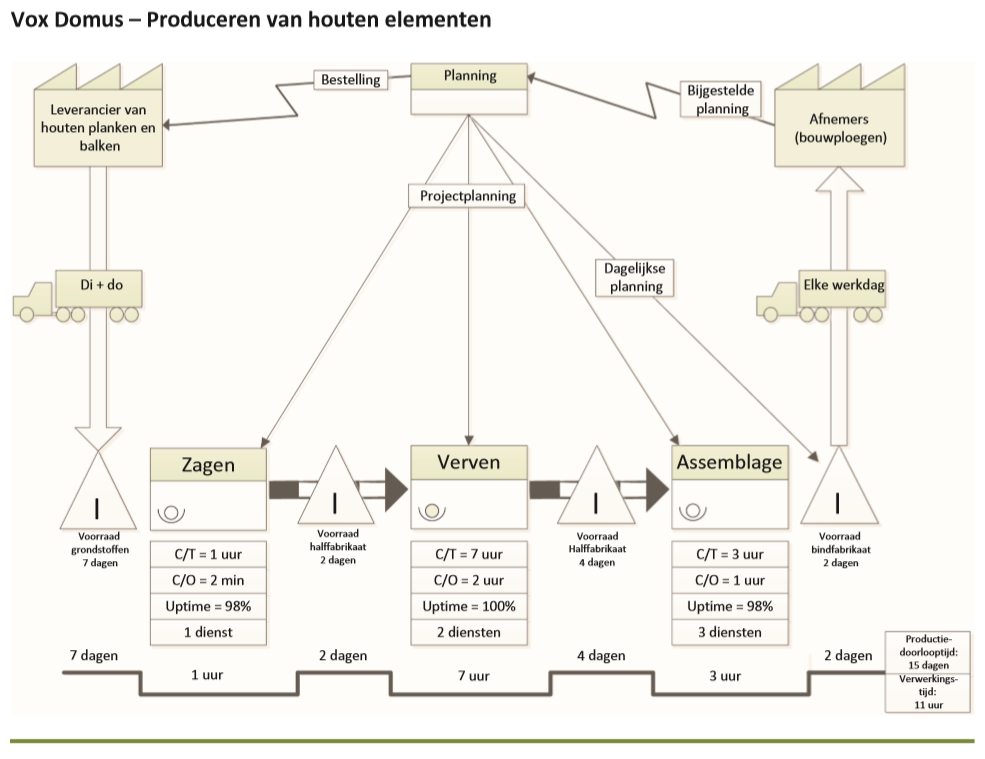

De value stream map Boom Management

Value stream mapping (sometimes called VSM) is a lean manufacturing technique to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Also known as "material and information-flow mapping", it uses a system of standard symbols to depict various work streams and information flows. Value-stream mapping (VSM) is a fundamental lean practice that involves diagraming a value stream, which includes all the actions (value-creating and nonvalue-creating) needed to move a product or service from raw material to the arms of the customer, including the material and information flow. A value stream map is a visual [2] tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process. [3] Value stream mapping (VSM) is defined as a lean tool that employs a flowchart documenting every step in the process. Many lean practitioners see VSM as a fundamental tool to identify waste, reduce process cycle times, and implement process improvement.

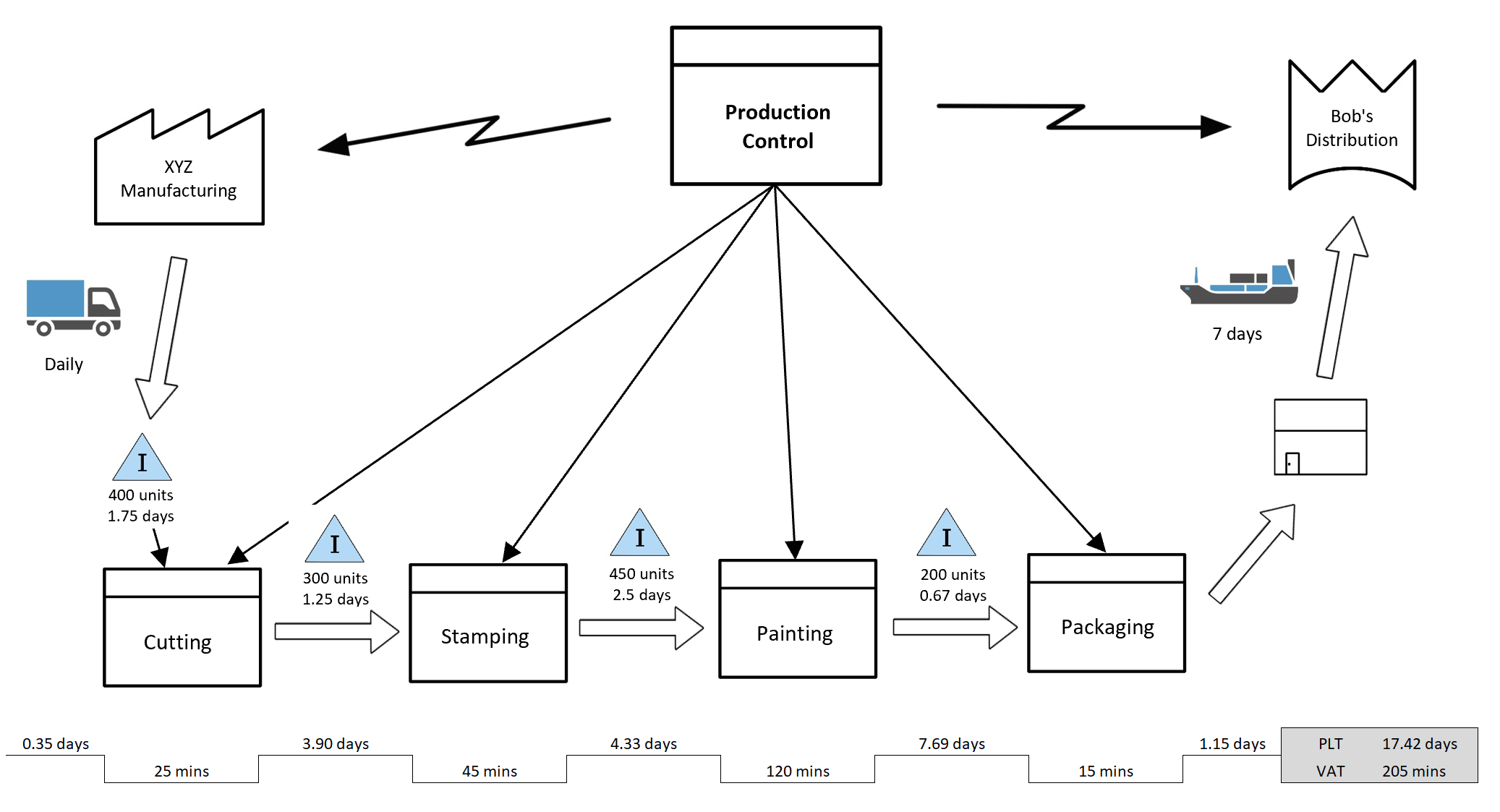

Value stream map example

Create a value stream map. Click File > New. Type value stream map in the Search box, click the Start Searching button, and then double-click Value Stream Map when it appears. From the Value Stream Map Shapes stencil, drag shapes onto the page to represent your processes, information, and materials. Use the connector shapes from the Value. 1. Determine your scope Figure out the start and endpoints of your value stream. When do you start adding value to the raw materials, and when do you hand the finished product off, either to a customer or another business? 2. Add objects for each step What steps do you take to prepare a single product or feature for the customer?

Definition, Working, and Examples. Value stream mapping (VSM) shows the events leading up to product usage to map inputs vs. outputs and reduces waste. Chiradeep BasuMallick Technical Writer. September 20, 2022. Value stream mapping (VSM) is a project workflow visualization tool that pictorially represents the events that lead to the user. A value stream map, in the simplest of terms, is a way to visualize the steps required to transform a customer request into a good or service, or in other words, a product's production path from supplier to the customer.

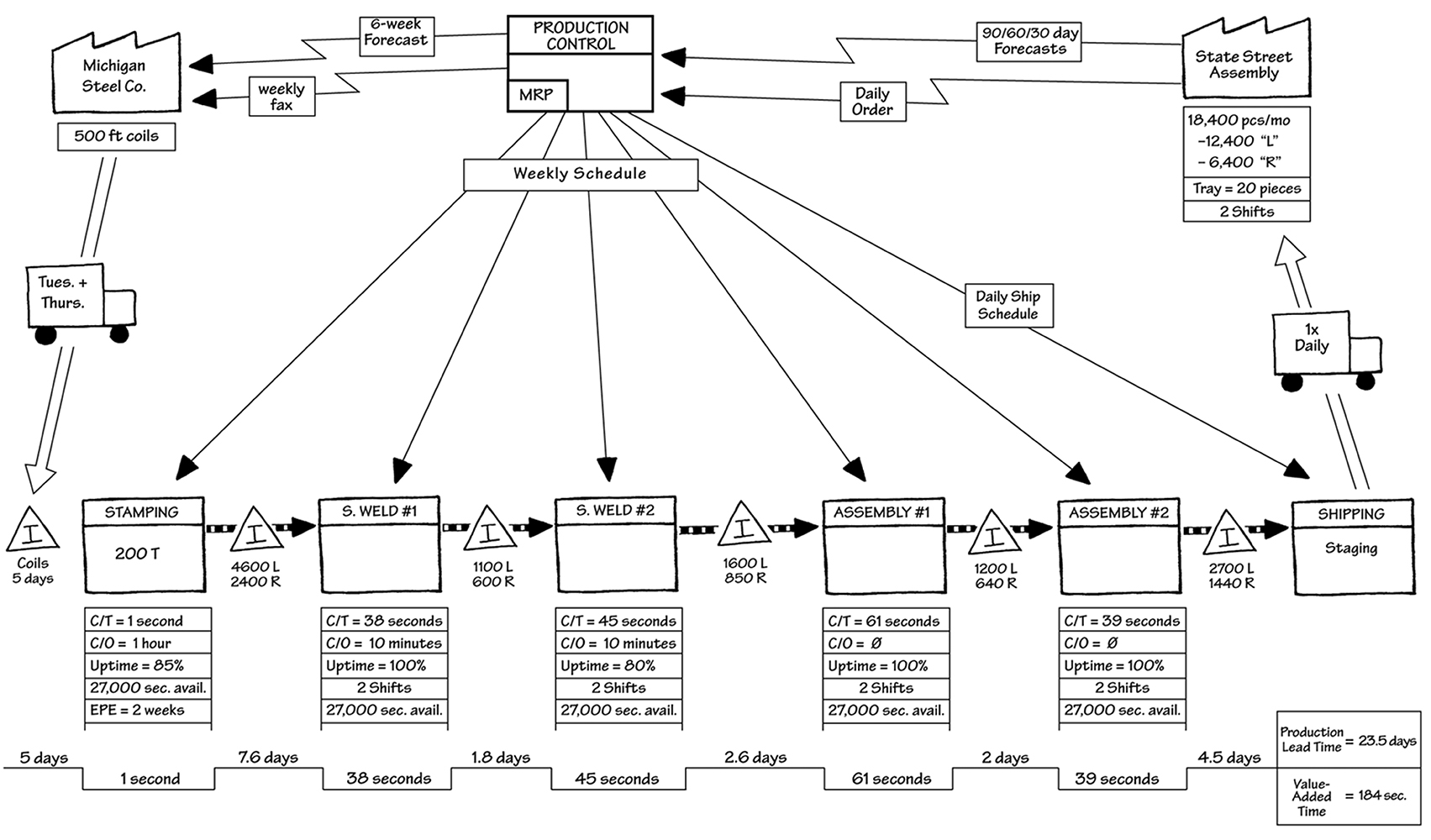

Value Stream Map Kaufman Global Lean and Operational Excellence

Step 2. Draw the entry and exit processes to the value stream (far right and far left portions of the page). Step 3. Create a map shell by drawing the processes (beginning from the furthest. What Are Value Stream Mapping Symbols VSM utilizes industry-recognized value stream symbols to map out all the processes from raw material to finished product. It is a graphical representation of the manufacturing process by including all stakeholders, processes, information, and materials in a flowchart.